Coal and Wood Tar Distillers

Tar distillers

Tar distillers process the oily tar recovered from charcoal plants, gas works and coke plants, they are often marked as 'Chemical works' on maps. From a railway modelling perspective these are similar in many ways to oil refineries, involving the use of rail tank wagons serving depots equipped with storage tanks. There were marked visual differences however, whereas the oil refineries tended to feature light coloured tanks and shiny pipes the tar distillers were generally black. Wood distillation is considered separately below.

When coal gas was widely introduced there was some public concern about the oily black by-product 'coal tar' that was simply dumped into the local rivers. People tried various applications for the tar, with the water content reduced it was found suitable as a protective 'paint' on buildings (rammed earth cottages had a black strip of tar around the base of their whitewashed walls where the rain might cause most damage). In the tar distillery itself a lot of the buildings were black with a coating of this material. It could not be used on boats and ships however (wood tar, discussed below, being a much more suitable material for this application). By the early nineteenth century someone had developed a method of producing 'roofing felt', essentially a woolen fabric coated in tar and then covered by sand. Roofing felt was popular in Germany and the USA throughout the nineteenth century but was less common in Britain other than on smaller flat roofed buildings.

Coal gas tar consists on a range of materials, basically divided into 'Naphtha' (valuable) and 'Pitch' (less valuable) with the once valuable creosote falling somewhere between the two. In the early days creosote and pitch were the only saleable products, the remainder of the distillates were burnt in a restricted airflow to make lampblack. The solid but fusible coal-tar pitch found a market as a binder for unusable small coal or 'duff' and anthracite dust, producing a first-class fuel briquette (by the early 20th century Britain was exporting large quantities of pitch to Germany for this purpose).

At first the tar distillers main objective was simply to obtain naphtha, which was used to make rubberised goods (the naphtha dissolves raw rubber), as a fuel for 'oil lamps' or simply to be burned in special chambers to recover 'lamp black' better known as soot (or carbon). Lamp black was used for making electric carbons, printing inks, shoe-blacking, patent leather and other goods but its most important use after the 1930's was in motor car tyres. Rubber tyres are actually about one third carbon, which makes the rubber much more hard wearing and accounts for the black colour. By the 1860's the lighter fractions were being further distilled to obtain benzene, toluene naphthalene & etc.

Naphtha is a generic term used for the assorted light distillates of coal tar, wood and petroleum. A ton of coal produced about seven and a half gallons of tar, of which about 60% ends up as 'pitch' and only about 5% constitutes the more valuable elements in the naphtha. After the valuable fractions have been recovered the residue is pitch, this ranged from a rather thick liquid to a solid material depending on the source of the tar and the processes used at the distillery (the solid type would soften at about 100 degrees centigrade).

One of the first valuable by-products from coal distillation was creosote, developed by a John Bethel of Bristol in 1838, this was adopted by Brunel as a preservative for railway sleepers on the GWR and became the standard wood preservative until it was phased out in the early years of the 21st century. Creosote is inflammable and for his timber fan viaducts Brunel had to resort to the older preservatives based on soluble salts (Kyan used mercuric chloride and Margary used copper sulphate, both of which leached out in rain water and required regular re-applications).

Products of coal tar have a staggering range of applications, the summary below is based on a wall chart distributed by the National Coal Board. The ammoniacal liquor provides liquid ammonia, sulphate of ammonia, sulphur and ingredients for wool scouring, soap, detergents and explosives Sulphuric acid is produced which is used in galvanising and for motor car battery acid. Carbolic oil contains phenols and cresols, the former are used in adhesives and aspirin the latter in sheep dips, tanning fluids and weed killers. This oil also contains Xylenols used in antiseptics and disinfectants. Benzole is used in perfumes and provides benzene used in petrol and for making nylon, toluene used for food sweeteners and TNT as well as the all important aniline dyes, and xylene, used in printing inks, paints and varnishes. Naphthaline oil is used in mothballs and also contains naphthaline used for disinfectants, antiseptics, fire lighters and dyes as well as phthalic anhydride used in disinfectants, antiseptics and plastics. The lighter oils in the naphtha's are used for brake linings, lubricants, photo chemicals and lino. Creosote oil is used as a wood preservative (until the early 21st century at least) and in aviation fuel and fuel oil. Anthracene oil is used as a spray for fruit trees, in the manufacture of dyes and as an additive for road tar. The residual pitch is used for making road tar, briquetted fuels, rust preventative coatings and for roofing felt.

One major application for the pitch produced at tar distillers was in making tarred macadam for road surfacing, much of which was shipped out in barrels (large wooden 'hogsheads' were used for this into the 1940s and possibly beyond) but in larger works a small fleet of tar lorries might be seen, these are discussed and illustrated in Appendix One -

Roads and Road Works. The loading facilities for the lorries would (typically) comprise a set of cylindrical steam-heated storage tanks (either vertical or horizontal), so you need to add the supply pipe from the rest of the works and steam heating pipes as well as the outlet pipe feeding the loading bay. The lorry loading system might consist of a simple elevated pipe on a metal gantry, it seems it was standard practice to simply have a light gantry to carry the loading pipe and hose, access being via the ladder on the tanker itself. The loading bay was typically in the open but might be covered with a simple corrugated iron roof but the structure would be open and would not require sides. For a gantry in the open a model railway signal gantry would serve, although the height would be reduced. There would be three or four pipes and hoses, the unused hoses simply laid back over the top of the gantry so they did not hit the lorry moving underneath. The livery shown below was taken from a photograph of a 1950s tanker but would apply to earlier vehicles.

Fig ___ Typical road tanker from about 1930

When gas works started using carburated water gas to heat their retorts, in about 1900 (achieving a higher temperature and great economies for the gas works), this drove off more of the valuable fractions and reduced the quality of the tar passed to the distillers.

When the country switched to North Sea Gas in the 1970s the tar distillers continued working, obtaining their raw material from the coke plants, both independent firms and those at steel works, several tar distillers (some of which had been owned by the local gas boards) were purchased by British Steel in the 1970s. I believe the industry, in decline by the mid 1970s, finally wound up in the later 1980s although there may be a few still operating as there are still a couple of coke and smokeless fuel works in operation (in the 1990s). As far as I am aware railway involvement in the coal tar business ended in the early 1980s (although they still supported the coke works).

Brief description of the process

Larger gas works would often process the coal tar on-site to some degree, selling the easily recovered products themselves. The degree of processing at the gas works varied considerably and a lot of unrefined coal tar was passed to distillers for processing as a dark red (almost black) liquid.

The tar from gas works or coke works includes a proportion of water (typically 5-10 percent), it was therefore necessary to put the tar in a tank to settle out (the water would eventually separate out and rise to the top). To facilitate this process the tank is heated slightly.

The unrefined naphtha, a deep amber to dark red liquid, was often delivered for further processing from the gas works where it had been separated from the heavy tar, in drums from smaller gas works or in tank wagons for larger establishments. A small coal tar works would often take in raw tar from a gas works and simply separate the black tar and dark red naphtha, selling the former and passing on the latter for further refining at a larger works.

Coal tar naphtha contains the more valuable light distillates usually lumped together under the general term 'Benzol'. A ton of coal only produced a few pounds of Benzol. Benzol is a mixture containing mostly benzene but also toluene, anthracene, xylene and the aniline so important to the dyestuffs industry. Benzene is highly inflammable and was used as an additive to (and in some cases as a substitute for) petrol in motor engines, National Benzole was a company trading petrol with this additive. Aniline is colourless but turns brown on exposure to air and light, it is one of the most important of the organic bases and as well as dyestuffs it is used herbicides, fungicides, photographic chemicals, in the making of urethane foam and pharmaceuticals. Over half the dyes used today are the nitrogen based 'azo dyes', the basis of which is naphtha. Since the 1930's however these chemicals have increasingly been obtained from petroleum oil at oil refineries.

Having extracted these lighter fractions the remaining coal tar is then passed to the Naphthalene plant where it is again heated to a slightly higher temperature (200-250 degrees centigrade). From this you can take the naphthalene direct as a white flaky powder or get heavier oils including carbolic oil.

At still higher temperatures (up to 400 degrees centigrade) you can extract creosote oil, a yellowish to dark green-brown liquid (also known as tar oil and occasionally as liquid pitch oil). This was used (mixed with other ingredients) to make creosote wood preservative, which was the standard preservative in use until the early 21st century (when it was banned as it contains traces of cancer causing chemicals).

The remaining tar, a thick black oily liquid is called 'pitch', was stored on site in a pit and shipped out in barrels or Graham Farish type tank wagons to be used for tarring roads and as a crude wood preservative. The tars used on road were defined by several standards which evolved over time, the tar used had to have certain distinct characteristics, which differed for coating chippings prior to laying and for adding the final top coating or dressing, hence by the 1940s the pitch required a degree of processing on site to obtain the correct elements.

During the Second World War experiments were made with introducing hydrogen into the lighter coal tar products to produce something akin to fuel oil (the process was called 'gasification') but this was expensive and was not followed up at the time. More recently there has been a resurgence of interest in this process, but this is mainly based in the USA.

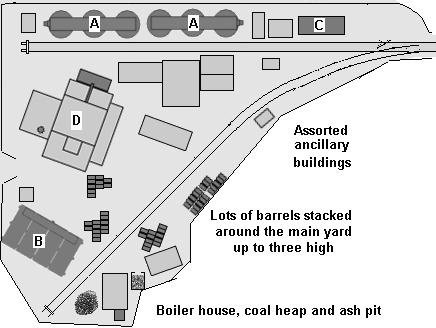

Modelling a tar distillers

The sign outside the works might mention (as well as the company name and contact details) 'liquid fuels, certified road tars, pelleted foundry pitch, naphthas, solvents, pyridine, creosote, coal tar chemicals, protective coatings, disinfectant fluids and pressure creosoting of timber'. This gives some idea of the importance of the industry.

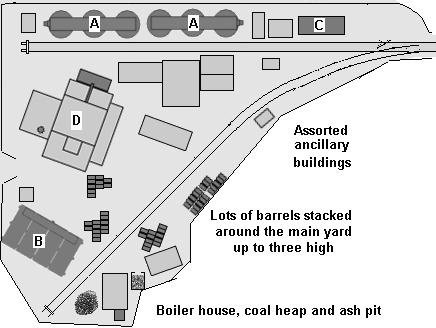

Coal tar distilleries had several distinctive features, not least being a large number of wooden barrels or (from about the First World War) steel drums for shipping out their products. The wooden barrels came in various sizes including very large 'hogsheads' used for (amongst other things) shipping road tar (see also Appendix One - Roads and Road Works) but they had almost all gone by the later 1950s and the standard 45 gallon steel drum was the norm.

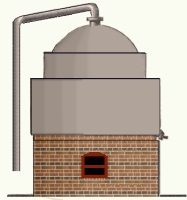

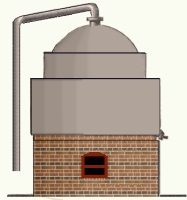

The main feature was of course the still where the tar was distilled, the original type were 'pot stills', a metal container set in a brick structure with a fire grate in the base. The flue from the fire grate was lead out to a single common chimney for a bank of stills. By the 1860s this method had been developed to divide the distillate into different receivers for different grades by slowly heating up the tar, the distillates from each temperature range being collected in turn. The pot had to be emptied of pitch after each batch had been processed and the resulting stop-go process was rather labour intensive. The size of the still was variable, typical sizes ranged from about 5 tons charge to 50 tons but most seem to have favoured the 10 ton sized pots as these could be processed in a single day.

Typical pot still for a tar distillers

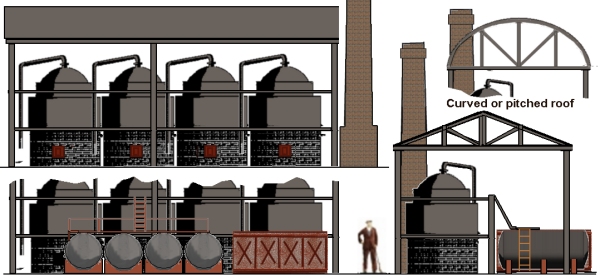

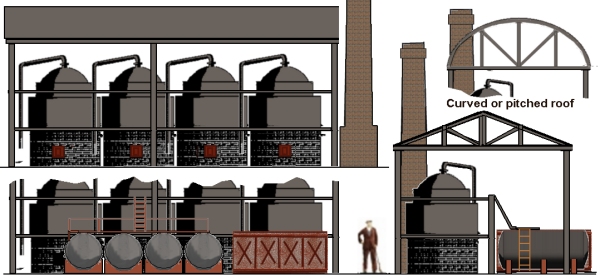

Several photographs of older works show a large building with no walls (the Ratio corrugated iron roof on Plastruct H section supports would serve in N). This covered a number of the pot stills with a walkway arranged near the top and a collection of receiving tanks on the ground level. Adjacent to this structure would be a chimney for the flue gasses from the pots and (as superheated steam was used in part of the process) there would be a boiler house with its associated chimney close by. In OO the standard 'party popper' would serve well for this type of still, in N, although rather large, they can be reduced in height and used, with florists iron wire for the associated pipework. You need five separate receiving tanks at the base of the still, one rather larger than the others for the residual tar. The outlet pipe from the still fed into a manifold so each grade could be diverted into a different tank as the process progressed. The sketch below is based (loosely) on a few rather poor quality photographs and although possibly inaccurate in detail makes a fair and recognisable representation of the prototype. Note that hand rails (wooden) where fitted would be on one side of the walkway only. There would be quite a lot of pipework, feeding crude tar in from heated storage tanks, the pipes at the top carried the distillate to a manifold (one for each pot) and thence into a series of storage tanks, the residual pitch would then be tapped off at the bottom of the iron pot and taken via a pipe to its own storage tank (at a number of sites this latter was just a hole in the ground but a large tank is easier to model)

Typical pot still building for an older tar distillers

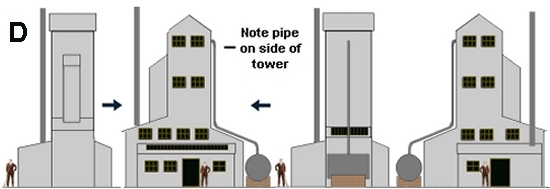

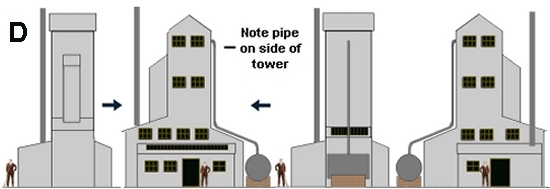

In the later 1890s the 'Lennard's patent continuous pipe still' was introduced, although many works stuck with the older pot stills into the 1930s as these required less technical expertise to run the plant. When the newer 'pipe stills' were introduced the old buildings with the pot stills would have been left standing, continuing to work whilst the new still was being commissioned and only demolished if the land was required for other duties. A pipe still works by passing the tar through a series of compartments, each at a higher temperature, from which the distillates are drawn and the pitch emerges at the far end in a continuous process. The Lennard still was usually enclosed in a tall structure (D).

Close by or attached to the still would be a furnace house (with a chimney about as tall as the still building which could be brick (round or square) or (by the later 1930s) metal). The still building shown below, sketched from photographs, has been reduced in size somewhat from the prototype to make it more manageable on a model although the general proportions have been retained. The prototypes were between sixty and eighty feet (18-24m) tall so modelled to full size it would tend to dominate the scene.

Lennard's patent continuous pipe still building

The still building was a light metal framework clad in corrugated iron, the internal diagonal frames could be seen crossing the inside of the windows, and roof lights were also provided as shown in the sketch. Timber cladding would be less suitable in such a works given the risk of fire. The building was either black (or a very dark colour) or painted a fairly light colour (stone seems to have been a popular colour for metal structures), but it would not be pristine and some degree of weathering is required.

There were other designs of still, and the Lennard design was itself modified over the years as the technology was developed. The example below shows a continuous tar still built in the very early 1950s but suitable for layouts set from the later 1930s on. Larger than the example shown above the central part of the building, clad in corrugated sheeting (probably metal but possibly corrugated asbestos sheet), housed a battery of four separate stills, the lower brick-built part of the building houses the reception tanks and control gear.

A 1950s enclosed continuous pipe still building

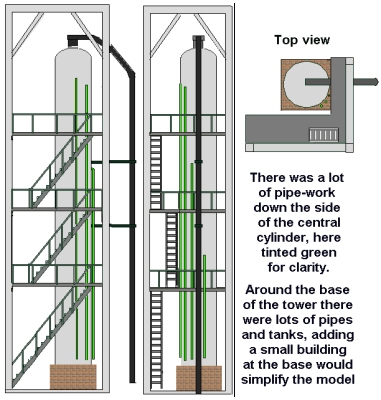

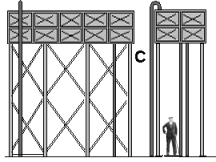

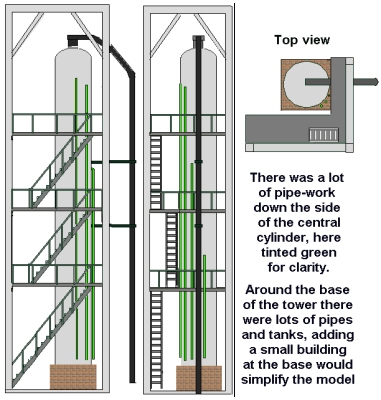

Some later stills lacked the building surrounding the still itself although this makes for a more challenging model. The still consisted of a tall frame with a large central pipe and smaller pipes arranged to either side, the early enclosed type lasted into the 1960s, the more modern enclosed type lasted into the 1970s (at least) and both those are easier to model. For those wishing to have a go the sketch below shows what I believe was the arrangement at one plant in the early 1960s. The L shaped frame was made up of H section vertical girders with i section cross members. Not shown are diagonal strips forming X shapes between the verticals although I believe the prototype had these. There was a lot of pipework down the central cylinder and at the base there were numerous tanks and a lot more pipework.

Open framed pipe still

There was a lot of elevated pipework on the site, as much of the product was hot this kept it clear of the men working. Each set of storage tanks would have loading and discharge pipes (florists iron wire is about right in N) and also steam heating pipes (for which I have used the finer florists steel 'rose wire' coated in 'Tip Ex' typewriter correction fluid to represent asbestos lagging). Up to the 1950s most works used steam pumps, supplied from a central boiler, which required heavy gauge pipes of about three inch diameter with large flanges at the curves and at about ten foot intervals on the straight runs. Florists iron wire serves, you can add the flanges by winding a length of cotton thread once round the 'pipe', supergluing it and trimming off the ends.

Somewhere on the site (until the later 1960s and least) would be the boiler house, for which one of the commercial models can be used (the chimney tended to be rather tall on these), and beside it would be a coal pile (often with a railway line for the coal wagons) and an ash pit (generally enclosed in a low brick wall to stop the ash blowing about the site). Many works switched to electric power in the 1960s but unless the land was needed the boiler house and chimney would be left standing.

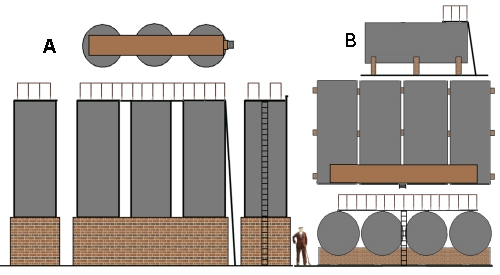

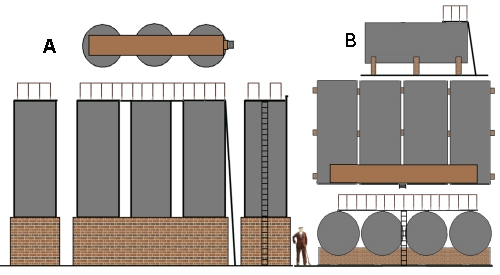

On site the products seem to have been stored mainly in tall cylindrical tanks (A) and a smaller number of horizontal tanks of slightly smaller diameter (B), one standard size for the vertical storage tanks was nine feet by thirty feet (2.74m x 9.14m). These tanks were referred to as 'boilers' but this was because they were heated with steam coils to keep the more viscous materials liquid. The vertical tanks often had a small 'lean-to' building at the base, presumably housing the valves controlling the steam and discharge pipes. These could be up to sixty feet high, for the purposes of modelling the illustration shows rather shorter tanks which will not overwhelm the general scene. The horizontal tanks were associated with loading products onto barrels and with assorted process control functions on the site, the former had the steam pipes on the top of the tanks with a walkway to access the valves. The examples shown are the storage tanks, the horizontal 'process control' tanks could be smaller than the storage tanks.

Tanks for tar distillery

Some smaller tanks were covered by a simple shelter, typically with one side missing and by the 1950s a lot of tar works appear to have had two or pressurised tanks (with distinctly domed ends), similar in size to the vertical tanks but laid horizontally side by side in a row.

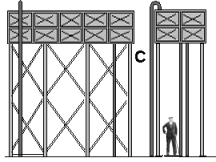

All tar works seem to have had tall 'water towers' (I assume they contained water), many of these were mounted very high (about fifty feet up to the base of the tank) and in two examples they appeared to consist of a series of iron tanks similar to those used for railway water tanks (the old Hornby Minitrix water tank would serve well), supported on a wooden or (more likely) metal trestle (C). Some of these water tanks were not so large however, and some were mounted on a brick plinth, so model railway water tanks can be pressed into service.

Tall (water) tank for tar distillery

The remainder of the buildings associated with the working of the plant would comprise an assortment of odd structures, some in brick, others clad in corrugated metal, a few clad in wood, some large and a few rather small. Several would have a chimney attached, although most of these were small, brick chimneys might be perhaps twice the height of the roof, metal 'stove pipes' rather shorter. I would suggest you need at least three tall brick chimneys, a mix of cylindrical and square section, for a post 1950s model add a couple of plain metal ones as well.

You would need an 'office' building, about the size of a small house (for which a house kit would serve, add a stair up the outside and an upper door to make it more 'office like'). There would probably be a small gate house where the lorry drivers would report and a mess room or canteen for the workers.

With any industry involving tall structures it is best to arrange these at the rear, leaving the area where your hand may need to go clear. Note that factory buildings were seldom neatly arranged on the site, and the site was seldom square, especially in this sort of industry where growth had been organic.

Add as much pipework as you have the patience for, much of it elevated, some lagged, connecting the various parts of the site but remember to leave space for lorries to access the yard spaces where they would be loaded with barrels, and (if included) road access to the tar sprayer loading bays.

Minimal tar distillery on corner of a layout

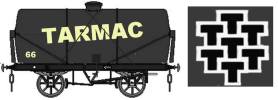

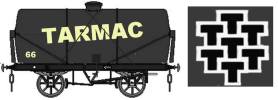

A likely customer for the products of the distillery would be Tarmac, formed in 1903 and for many years using coal tar for their tar-coated chippings business. Tarmac tanks were all black with a yellow logo and number. In 1964 a new '7 t's' logo was introduced, but this was not (as far as I know) put onto the older rail tanks.

Fig ___ Tarmac tank and post 1964 logo for lorries

In the 1920s and 30s there were several firms who used rail transport for the tarred stone chippings, however to date I have only seen reference to Tarmac branded tank wagons.

Notable British Tar Distillers

It is impractical to cover the details of all companies trading in coal tar products, a good start for anyone interested in these areas is Mr. R. Tourret's book 'Petroleum tank wagons of Britain' (see bibliography for details) which includes a number of tank wagons of common design employed in this trade. There were also tar distillers in many of the larger gas works, a fleet of rail tanks operated in the rather plain livery of 'Benzole Producers Ltd from the gas works sites, their Class A tanks had either BENZOLE or BENZINE written in large lettering on the sides with the comapny name and 'home' depot details in the lower left of the tank in small lettering.

British Tar Products and Lancashire Tar Distillers

Both based at Cadishead (Irlam near Manchester), these firms were operating tar tank wagons in the 1930s. I believe the works was still operating into the 1970s although the last photo I have seen of the British Tar Products wagons dates from the 1960s. Lancashire Tar Distillers was still operating in the 1990s, although I am not sure what their trade was it involved importing 'hazardous waste', by the later part of that decade the sidings were being described as 'former' and 'defunct', but I am not sure when rail traffic ceased. These sites were very close to the Manchester Ship Canal and in the 1960s a ship loading benzene managed to spill some into the canal, this washed down to the nearby ferry where it was ignited by something (probably a discarded cigarette) and the 'canal caught fire', seriously burning one of the ferry passengers.

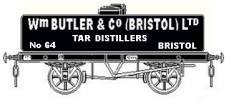

Crews Hole Tar Works was set up by Isambard Kingdom Brunel about three miles from Bristol city centre to produce creosote for the GWR. Following a fire the works was sold in 1863 and became Wm Butler Tar Distillers. Butlers operated works in Bristol and also at locations in Gloucester and Gloucestershire. They were (I am told) a big user of rectangular railway tar tank wagons, some of which were lagged (unusual on this type of wagon) and hence had a very 'square' body with no rounded corners.

Butler's tar tank

They hived off their tar business in 1952, setting up the Bristol & West Tar Distillers (partly owned by the gas board), who also operated tank wagons in their livery at least into the 1950s. When North Sea Gas replaced coal gas Bristol & West Tar Distillers was bought by British Steel in 1970 and continued to operate until 1981.

Midland Tar Distillers, based at Oldbury in Birmingham. The company merged with Yorkshire Tar Distillers at some point in the 1950s or 1960s to form Yorkshire Midland Tar Distillers, the joint company was purchased by Croda (see below) in 1975.

Yorkshire Tar Distillers (also based at Oldbury near Birmingham) was formed by a merger of various gas companies and tar distillers in 1926 and traded at least into the mid 1970s. The company merged with Midland Tar Distillers at some point in the 1950s or 1960s to form Yorkshire Midland Tar Distillers, the joint company was purchased by Croda in 1975. Yorkshire Tar Distillers had a fleet of 463 wagons at 1961 reducing to 420 in 1967.

William Briggs & Sons Ltd (based in Dundee) dealt in fuel oil and bitumen. Their original refinery was built on the Dundee site in 1931 adjacent to Dundee Gas Works, to process the coal tar produced at the gas works. Typical throughput was in the region of 100,000 tons per year and the plant produced a range of distillates including gas oil, marine diesel, lubricating oil base stocks and fuel oils are also produced. The company operated tar tank wagons, some supplied as late as the 1950s. In the 1920s the tanks as built had William Briggs & Sons Ltd in capitals along the side, with the wagon number below, by the post war era this had changed to the livery shown below, but I do not know when that change occurred.

Fig ___ Briggs tank

Briggs Dundee works was sold to Tarmac in 1968 and In 1992, the bitumen interests of Tarmac were acquired by the specialist Swedish refiner Nynas Petroleum Group.

Joseph Turner and Co. operated from Queensferry Chemical Works (became part of Midland Tar Distillers Ltd in 1933), the works closed in 1947

Croda Ltd was founded in 1925 at Goole, for the extraction of wool-grease from seed-cake produced by the Bradford wool-scouring mills, and soon after lanolin was produced from this source. By the early 1960s Croda was well known as producers of emulsifiers, lanolin, lanolin alcohols, plasticisers, and anti-rust and protective preparations a vast range of paints, finishes and oils for all purposes, and for hydraulic and de-icing fluids. At about this time they started buying into the tar distilleries and this developed into the Croda Organisation covering a wide range of by-product related chemicals.

Peterborough and District Tar Distillers. Operated tank wagons in the mid 1930s.

South Eastern Tar Distillers. Based at Tonbridge in Kent, operated tank wagons (rectangular) in the 1930s

South Western Tar Distilleries. Southhampton, operated tar tanks in the 1940s.

Tar Residuals Ltd. Had an office at 27 Albemarle St London W1 and operated some tank wagons.

Wood Distillation

Small 'Chemical works' or 'Acid Works' shown in forested areas on Ordnance Survey maps are probably wood distillation plants. These took in stuff called 'cordwood' (see also the wagon loads section), basically odd bits of branches and thin tree trunks, and heated it in large kiln like retorts sealed from contact with the air. This drove off the oils in the wood to produce 'Pyroligneous Acid' and residual tar. The 'acid' contained mostly acetic acid but also a range of useful chemicals such as naphtha, turpentine, acetone and methyl alcohol shipped out in drums (or very occasionally in tanks), acetate of lime (a powder) in bags and of course charcoal (shipped in bags). Not all works processed the acid on site, some shipped it for further refining to another, larger, works.

In areas where pine trees were grown these establishments produced turpentine, a complex oily resin which is distilled to produce a range of useful materials including 'rosin' (used to coat violin bow strings), 'thinners' for paint and as a source of synthetic camphor oil (natural camphor oil is produced almost exclusively in Taiwan by steam distillation of the camphor tree wood itself). The products of pine trees, turpentine, pine oil, tall oil and especially rosin and the residual tar or 'pitch' are sometimes referred to as 'naval stores' as they were used for repairing wooden ships.

Where hard woods were abundant (birch, alder, oak and beech) the main product was usually acetic acid, shipped out in drums. The acetic acid was used to manufacture sodium acetate, a useful mordant for the cloth dyeing industry (see also Lineside Industries - Paints, Dyes and Inks). Acetic acid produced from wood distillation was cheaper than that produced from malt vinegar. The residual tar was shipped out in barrels or in bulk using tank wagons, other outgoing cargo would include sacks and casks.

The sign at the entrance might include mention of 'wood distillers', 'chemical works', 'acetic acid', 'charcoal' and 'blacking millers' although chemical works (where the trees were mainly pine) and acid works (where hardwoods were abundant) seem to have been the most common.

There were quite a number of smaller works which did not process the liquor on-site but shipped it out for further refining. These smaller works would comprise the retorts (invariably with a tall chimney) and a few ancillary buildings including (often) the home of the owner or manager of the plant. The retort might be made of brick but could be an iron box. The vapours driven off were passed via copper pipes in which the vapour condensed and ran down into large wooden barrels. Once full these were left to settle out, the tar falling to the bottom, the 'acid' floating to the top. The acid and tar were then decanted into fresh barrels for shipment. Such a small works would only just qualify for a railway connection. There was a lot of wood lying about and most works had a saw (often water powered) to cut up the timber for the cradles.

In forested areas 'works' were often rather large establishments, with large buildings several stories high to contain the various settling tanks involved in the process. There is a complete description of this process and numerous useful photographs of the installations in the book 'The Severn & Wye Railway Vol. 2, published by Wild Swan publications.

Access to the railway was a major advantage for a larger works, some works were arranged to either side of the local branch line, these would have a level crossing (an 'occupation crossing') or perhaps a small bridge to allow works traffic to cross the line. These large works would process the liquids recovered to obtain a range of chemicals.

The wood was cooked in the retort without being allowed to burn, over two thirds of its weight being given off as gasses which were extracted via large copper pipes from the top of the retort. After about a day the cradles were pulled from the other end of the retort and placed in a similar structure which was cooled with water, the end product being charcoal (about a ton of this being produced from 5 tons of the cordwood).

The gas meanwhile had been passed through a condenser which dropped out most of the heavier tar (which was drained into a large tank), then to a series of stills called 'separators' where the acids, oils and water were removed.

The still hot gasses and vapours from the separator were passed to further condensers where naphtha and further acids were extracted. Naphtha is not a substance per se, it is a generic term for a range of liquids found in petroleum, coal tar and wood tar. The gasses which did not condense in this process were used to supplement coal in the furnace used to heat the retort.

The naphtha/acid mix was passed to storage tanks (iron vats, perhaps 10 foot across and 8 foot high, usually under a simple 'carport' type cover of corrugated sheeting on a simple wooden framework). These tanks were heavily stained black (although I am not sure if this was from the process or some kind of protective coating), and there was a raised walkway provided for inspection purposes. As far as I am aware they were open topped. Further distillation and processing, all conducted indoors, produced grey acetate of lime powder, and methyl alcohol (wood alcohol).

Incoming cargo would include cordwood (as described in the wagon loads section), lime in roofed wagons, sulphuric acid and caustic soda, both often shipped in spherical glass carboys as mentioned under wagon loads. Sulphuric acid can also be shipped in iron tanks (see also Lineside Industries - Chemicals, salt and plastics industries) and caustic soda can be shipped as a liquid in tanks or as a white pelleted material in small metal drums holding 10 lbs.

A 'cord' of wood is a measure of volume, being 128 cubic feet. The wood was stacked at the factory about 4 feet wide by 4 feet high, hence every 8 feet was a cord. This wood was loaded into cylindrical metal cradles about 6 foot

in diameter and 10 foot long running on railway tracks. These cradles were wheeled into the 'retort', a rectangular iron box 7 or 8 foot square or a fire-brick structure with a flattish curved roof of about the same size with large doors at either end and long enough to hold several cradles. At least one 'acid works' in Scotland had the retort in what looked like a long garage with a pitched roof of corrugated iron, so you have considerable leeway on how much work you need do in that department.

Acid Works were still operating certainly into the later 1970s but since the later 1960s there has been an increasing demand for charcoal and new methods of producing it have been developed. Some firms use waste sawdust and shavings from other industries and a lot of charcoal is now sold for use in bar-b-que fires as 'briquettes' (formed lumps of powdered charcoal mixed with starch and a little water). The byproducts which used to be so important can still (in many cases) be sold on (methanol, acetic acid and wood oils). Some specialist markets remain viable (for example wood methanol can be used as a denaturant for ethyl alcohol) but I am not aware of any wood based chemical firms still operating in the UK. Having said which chemicals and materials recovered from wood today include; Acetic acid, acetone, cellophane, cellulose, acetate, charcoal, dyestuffs, ethyl alcohol, explosives, lacquers, methanol, molasses, oils, photographic films, pitch, plastics, Rayon, sugars, synthetic sponges, tannins, tar, turpentine, vanillin, yeast, etc.

More modern products include ablative carbon composite (made of wood reduced to long filaments of carbon) capable of withstanding temperatures of up to abut 6,000 degrees Centigrade (5,000 degrees F) and carbon fibre composite or structural graphite composite, which is stronger and lighter than metal.

^

Go to top of page