Goods Yards

A goods yard is a set of sidings where the wagons and vans were loaded

and unloaded. On model railway layouts the goods yard is normally associated

with a passenger station, in larger towns however a separate 'goods station'

was provided, although parcels traffic and mail seems to have been

traditionally handled within or close by the passenger station. The railway

goods yards handled all the traffic carried by the railway which could not be

dealt with at local private sidings, and up to the 1950's that means most of

the goods moved in Britain.

In its most

basic form a goods yard might be a single siding run behind one of the

platforms but it was usual to provide more comprehensive facilities even at a

very small station. Note that simple does not mean small, goods facilities at

even a small country station often required much more land than the passenger

side of the business. For one thing the passenger could walk onto the

platforms, goods yards had to provide access for horse-drawn waggons and carts.

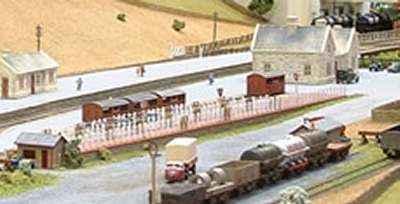

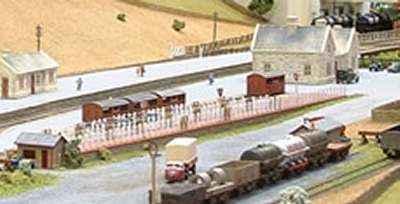

The photo below shows the original goods yard on the late Andy Calvert's Moorcock Junction layout (a fictitious junction station on the Settle and Carlisle), inset bottom left is Andy's goods shed. The period represents the years of 1957-1962.

Fig___ Goods Yard on Moorcock Junction layout

Photo taken at the N Gauge Society 35th anniversary exhibition, reproduced courtesy and copyright

N Gauge Society and Bob Harris, the current owner.

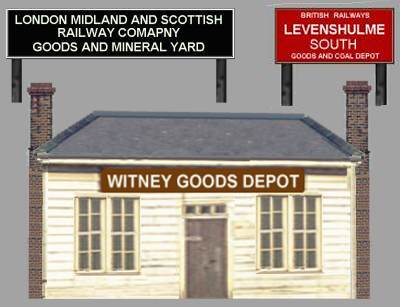

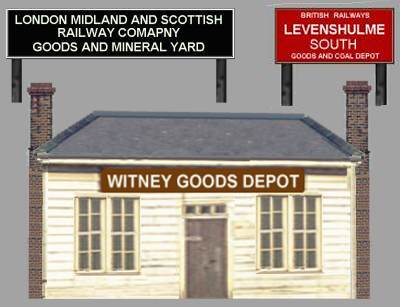

The yard entrance usually had a sign, examples of which are shown below. The LMS sign top left and the BR(MR) sign top right were both taken from photographs of Levenshulme goods depot in Manchester, both were mounted on heavy timber posts to the right of the entrance gate. This yard incorporated a coal yard serving several merchants. The building bottom was originally the passenger station building but served for many years as the goods yard offices, it was located just inside the entrance to the yard, clearly visible from the road, the sign is a BR(WR) enameled metal type.

Fig___ Signs associated with goods yards

The signs in pre BR days usually mentioned the company name, where that company had more than one yard in close proximity there might also be a station name. In the BR era, when all the stations were operated by BR, the station name was usually mentioned (there might be several goods stations associated with a town), however I am told not all BR signs were station specific, some were generic, as on the BR Eastern Region sign shown below. These would presumably be supplied where the entrance to the goods yard was directly from the passenger station forecourt area, where the full station name would of course be displayed.

Fig___ BR goods yard sign

As well as the large signs indicating the entrance to the yard various signs were seen inside the yard itself, the examples shown below are in the various BR regional colours but similar signs would have been seen in pre-nationalisation yards.

Fig___ BR era signs from within goods yards

Although there might be several general

goods freight trains passing along a line during the day generally only one

would be scheduled to spend any time shunting the average station goods yard.

This shunting might take upwards of an hour or more as individual wagons were

placed in the most convenient locations for loading or unloading. When shunting

was in progress it was normal to clear the area of traders vehicles. Shunting

was done at fixed times of day but on a model of a busy town goods station the

best compromise might be to have a siding or two containing wagons and vans

with their doors open surrounded by road wagons, the remainder of the sidings

being clear for shunting.

Country

lines often had only five passenger trains each way and perhaps two goods

services per day. I think it was C. J. Freezer who first mentioned in print the

advantages of modelling a town location for a model railway; the land was more

expensive, so the facilities were more cramped, and the services tended to be

rather more intensive than the country branch, all of which lends itself rather

well to modelling. In towns and cities there was also considerable to-ing and

fro-ing between the yards of the various railway companies as well as the

trains coming and going on the main and branch lines.

Basic Yard Facilities

A typical goods yard would have several typical features, almost all would have a raised bank allowing sack trucks to access wagons (where this was not available one solution was to drop the wagon door onto a large barrel and lay a plank up against this, however this was really only suitable for wheelbarrows). There was almost always a lockable shed, a great deal of the goods in transit was 'sundries' or less than a wagon load, placed in a wagon or van with other goods head to the station. This material had to be unloaded from the wagon and either delivered by the railway carters or set aside to be collected by the consignee. The goods shed served to allow this work to be done under cover and usually contained a lockable secure store for more valuable goods awaiting dispatch by rail or collection

by a local consignee. In many yards the raised loading bank was entirely confined to the inside of the shed.

Goods sheds were

in the main rather large buildings, often larger than the main booking hall at

the associated passenger station. Most sheds were single storey (albeit as tall as a two storey house) but a few had warehousing on

upper floors.

The photo below shows the goods shed on the late Andy Calvert's Moorcock Junction layout, with the two road engine shed in the background.

Fig___ New Goods Shed on Moorcock Junction layout

Photo taken at the N Gauge Society 40th anniversary exhibition, reproduced courtesy and copyright

N Gauge Society and Bob Harris, the current owner.

At large goods stations the goods shed might be a very large building

with several tracks passing inside. These large depots were often multi-storey

affairs with road access at ground level and the railway entering on an upper

floor. Where this was done it was not uncommon to have a wagon lift to move

loaded and empty wagons between the different levels, one example in Birmingham

had the lift in the open and I understand that the large goods depot close by

the former Central Station in Manchester had such lifts inside the building.

Smaller goods sheds of the Ratio type, in

which a single railway siding passes through the shed with doors at either end,

were common but in some yards (especially on branch lines) the siding passed

along an outside wall with just an awning above the door to the shed. Railway

companies often had standard designs of goods shed but odd non-standard

examples were built on many lines. Peco offer a neat little wooden shed

representing about the minimum size for this kind of building. The Peco model

is designed to stand on its own but it can be easily adapted to sit on a

loading bank.

The Peco shed lacks any foot access as supplied, this is easily rectified by adding an extension below the road-side door with a flight of steps at one end (the last time I used this model I added a ramp on the opposite end of the extension as well). The Ratio goods shed has such an arrangement already.

Fig___ Ratio N Gauge goods shed

Almost all goods yards had a hand powered crane of some

description, the goods sheds with the siding passing through the building often

had a crane or two inside mounted on the heavy timber supports (the Ratio yard crane serves well if the interior is to be visible), the example shown below is typical of the kind used inside smaller sheds, although this example was in a rail-canal transit shed.

Fig___ Typical crane inside a shed

For larger goods such as railway containers and bulky loads such as timber a separate crane was usually provided alongside a siding in the open. These external cranes were often standard railway company designs but there were also examples of non standard cranes and even quite large 'scotch derrick' type cranes, the latter being particularly associated with heavier types of traffic (see also Wagon Loads & Materials Handling - Materials Handling - Hoists and Cranes).

In practice quite a lot of

traffic was unloaded from railway wagons directly onto road vehicles and if you

have a two or more sidings out in the open for this remember to leave enough

space between them for a horse drawn cart to turn round. It is not practical to

back up a horse drawn vehicle, the harness is not designed for it and the horse

would not appreciate it. Where you see recessed bays in goods sheds for carts

it would be normal practice for the horse to be unhitched and the wagon to be

shifted by hand into the bay. At smaller stations single tracks would fan out

but at busy yards the sidings were usually laid in pairs, allowing road

vehicles access to two sets of wagons.

In the more confined in-town yards (town land was expensive) the distance between the lines might not allow a cart to be turned, instead the track was inset so, after loading, the cart (or lorry) could proceed to the end of the rake, accross the line, and return up the other side. In N the minimum distance between the

outside edges of the sleepers on tracks in the open needs to be about one and a

quarter inches (32mm).

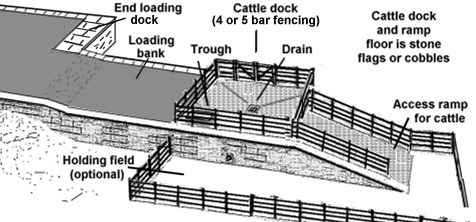

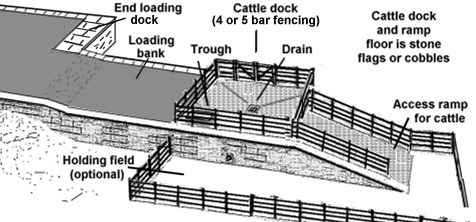

Cattle were handled at a separate raised loading bank

called a 'cattle dock'. These were usually equipped with pens of some kind, the

extent of the facilities would depend on the amount of cattle traffic likely to

be handled. Some country stations, where land was cheap, had a small holding field close by the cattle dock. The floor of the cattle pens would be flagged and would usually have a drain or drains with associated gutters cut into the surface. Cattle need regular watering so a stone or metal water trough was (I believe) always provided.

The photo below shows the large cattle dock on the late Andy Calvert's Moorcock Junction layout.

Fig___ Cattle pens on Moorcock Junction layout

Photo taken at the N Gauge Society 35thth anniversary exhibition, reproduced courtesy and copyright

N Gauge Society and Bob Harris, the current owner of the layout.

Ratio offer a very neat kit of a standard GWR type cattle dock with

two pens, this can be extended using additional kits if required but most

stations had only one or two pens. A more common type consisted of a simple wooden fence with pairs of gates, note that you cannot (or at least should not) use standard three rail fencing, pigs are small and sheep can jump, so you need four or preferably five bar fencing. This is not available commercially so you have to make it from 20x30 thou strip, single strips for the horizontals with pairs of verticals and the gaps filled either with short off cuts or Milliput.

Road

vehicles and farm machinery might be handed at the loading bank if they could

be manoeuvred over the side of a drop-sided wagon. If no loading bank was

available, they could also be lifted on and off using a crane. It was fairly

common practice to provide an 'end loading dock' to allow over-the-buffers

loading of flat wagons and machinery wagons. The end loading dock was sometimes

combined with the cattle dock and where this was done the end loading part

would be slightly higher than the main cattle dock. On these combined loading

banks it was usual to have a short section clear of the pens for side loading

of wagons.

Fig___ Loading bank with cattle dock

To handle private carriages and

later motor cars passenger stations sometimes had an end loading dock built

behind one of the platforms, these were referred to as a 'carriage shoot'.

Carriage shoots consisted of a short length of track running into a bay in the

platform or along one side to a dead end and they also provided a handy

unloading point for van loads of parcels. My local town station at Altrincham

was (and remains) part terminus and part through station. The terminus side

actually had two sidings feeding the end loading 'carriage shoot'. These were

quite long but this was because they accessed the main station approach road

which was at the far end of the platforms.

Some degree of yard lighting would be provided, at the bottom end of the scale this

might be a couple of bracket mounted oil or gas lamps fitted on the goods shed, or a single

lamp post on a loading bank. The larger the yard the more lights would be

provided, most would be fairly tall types, although where sidings were provided

for road traffic access the lamps used were often about the size of street

lamps and in marshalling yards lamps on nine foot tall posts were often provided at the throat of the yard to assist staff reading waybills and the like. There are several models of suitable lamps (some working) available. The example shown below left was still in use in 2007 and the remains of similar but rather shorter lamps with inclined ladders (shown below centre) were still in place at a former goods marshalling yard. The loop with suspended gas light seems to have been a fairly standard post mounted design across the country, by the 1930s these were often fitted with electric lights rather than gas. Street type lamps similar to the Ratio N Gauge platform lamp shown below right were seen on loading banks and cattle docks, but were less common set amongst the tracks in the yard.

Fig___ Typical yard lighting

In the larger marshalling and goods yards electric flood lighting using tall towers with batteries of lights were in use by the early 1950s although I am not sure when they first appeared. An etched brass kit of one of these tall lighting towers is available from (I believe) Taylor Plastic Models.

One point that

seems to be forgotten these days is the provision of 'fire buckets'. These were

plain metal buckets, painted red, often with the word FIRE printed on them in

white or black, filled with water or sand they were seen in almost all outside

locations up to the 1970's. Most railway platforms had a set of the these

buckets and they would be seen in factories, store yards, schools, hospitals

and especially near anything flammable. They were usually hanging in groups of

three from a red painted wooden boards screwed to a wall or from a similar

board supported on two wooden posts about five foot high.

Stables for

horses, used for hauling the railway delivery carts and sometimes for shunting,

would be seen on or close by even quite a small goods yard. These were usually

well built structures, commonly in a similar architectural style to the goods

shed. At my local station (Hale on the Manchester to Chester line) the stables

were just outside the yard entrance, built onto the end of an adjacent row of

terraced houses.

The local coal merchant would often rent some space in the

station goods yard, often with a dedicated siding. The alternative, which was

seen occasionally, was for the merchant to collect the coal in bulk using a

road cart or waggon and haul this to his own premises. The facilities provided

for coal merchants are discussed in detail in the section on Railway Company

Goods Facilities - Coal.

The local coal merchant

with facilities in the yard might also stable his horses in the immediate

vicinity of his coal bins, this was unusual but makes for a nice model. One

option here, in the country at least, would be to have a couple of old grounded

van bodies being used as the stables.

Local

traders dealing in materials such as agricultural fertiliser might have a shed

of some kind in the yard, these might be anything from a large warehouse type

building to a simple wooden hut. Old railway van bodies were quite often sold

for use as sheds (mostly by farmers rather than in the goods yard) and the Peco

ten foot wheelbase refrigerator van makes a good basis for this. For layouts

set in the 1920's or 1930's this should be backdated with external timber

framing and possibly with new sides if you feel up to it. Some of the old

wooden outside framed van bodies remained in use into the 1960's. Grounded van

bodies and small 'garage sized' sheds were usually set back from the railway

but some sheds were positioned beside a siding and raised to platform height to

allow easy transfer of materials to and from rail wagons and road vehicles.

The example shown below was operated by a seed and feed merchant, the comany name and town in the upper part of the ends, on the lower part of the ends it said 'Agents for Bibby Oil Cakes, Linseed Cakes, Cotton Cakes etc'. The prototype was light colour (possibly 'light stone') with dark writing. The base is brick with corrugated iron walls and roof on a timber framework.

Fig ___ Private rail served warehouse

Ratio offer a concrete shed raised up on

piles in their OO range of kits. This is a British Railways Southern Region

standard design, made up of pre-cast modules which could be assembled in any

number of ways. These sheds were seen everywhere on the system from the later

1950's from Cornwall to Scotland and were often leased to private traders or

major shippers (notably suppliers of animal feeds) as small warehouses. Fertiliser distributors seem to have made

frequent use of these sheds in country areas and this became very common as the

railways ended their less than wagon load services. The picture in the Ratio

catalogue can be used as a general guide to appearance and practice and the

shed can be built up from a box of 40 thou plastic card with 1mm wide strips of

10 thou representing the vertical supports. The vertically planked wooden doors

can be a simple rectangle of 1mm scribed card. These buildings, being modular,

could be built to any required size and I believe the Ration model as supplied

represents about the smallest that was actually used. Wooden bodied sheds of similar dimensions with a corrugated iron or asbestos roof were also used.

The wooden bodies of old railway vans and even old four

wheeled coach bodies were sometimes used as 'mess huts' or store rooms in

railway yards. The Graham Farish four wheeler coach body can be used but if you

cannot find one of these you can cut down a Graham Farish 'suburban' coach to

suit quite easily.

From the 1960's the old grounded van and coach bodies

steadily disappeared and after about 1970 the standard 'portacabin' became the

norm. There are now several suitable models on the market, these are discussed

in more detail in Volume 2.

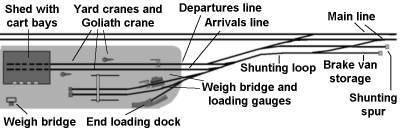

Larger Town Goods Facilities

The railways divided goods services into four basic categories. Small items were classed as 'sundries' and the high value 'parcels' variety were often dealt with at the passenger platforms. Really big items required cranes and the like, in towns these would be dealt with in a 'heavy goods' yard (usually an area within the main goods yard). People could send their goods 'station to station' making their own arrangements for delivery and collection. The smaller items came under sundries traffic but quite a lot of this traffic provided full wagon loads and this traffic would be handled in sidings in the open where the customers vehicles could pull up alongside the siding. This siding would also be used by railway company vehicles handling full wagon load traffic.

The railways also handled a lot of the collection and delivery work themselves and in towns they provided large goods sheds for this traffic. Typically such a C & D depot would require a minimum of two tracks entering the building, one for goods arriving the other for outward traffic. Loading bays would be provided

for road vehicles, and there might also be road access to the interior of the

building to enable the transfer of things like sacks of sugar to take place

under cover. The entrances for road vehicles, were generally much higher on

older buildings. Horse drawn vans were often quite tall and the driver sat on

top, also open horse drawn wagons could be loaded up rather high.

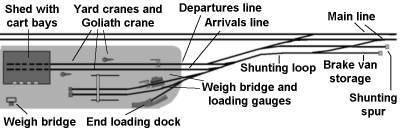

Fig___ Minimal large town goods yard

Note - In this example coal traffic, and possibly cattle, are dealt with in separate dedicated yards. Coal would always have dedicated sidings, the cattle pens could be accommodated on the end loading dock but the loading bank is provided here for horse traffic.

An arriving goods train would be brought from the nearest marshaling yard, usually by a small tank engine, and deposited in the arrivals side. The individual wagons would then be unloaded and the goods transferred to the waiting road vehicles for delivery. Often the required road trailer or cart was not on hand so piles of goods awaiting collection were a feature of this side.

Once the railway stock was empty it would be shunted out of the building and back in to the 'outgoing' side, where there would already be piles of goods waiting to be loaded. On this side there were usually numbers indicating where on the loading platform wagons for specific locations would be parked.

In larger town goods yards the goods shed often resembled a passenger

station, light wooden

bridges were provided to enable the staff to walk or manoeuvre trolleys from

one platform to the next without going all the way to the end and back up the

other side.

In larger

goods stations there might be separate sheds for arriving, departing and

transhipment.

Transhipment relates to the unpacking of goods from wagons and

re-sorting them into other wagons for onward shipment. This was often required as a small consignment going from London to Leith (near Edinburgh) would be unlikely to form part of a full wagon load for that destination. It would be placed in a wagon or van heading North and then transhipped at a goods depot closer to its destination, where a full wagon load of goods would me much more likely. Such a shed could have as few as three platforms with two double-track sidings running between them. The tracks to either side of the central platform would handle the transhipment from one wagon to another whilst the outer platforms would handle the local traffic for collection and delivery.

In larger sheds there might be three tracks between the arrivals platforms, the centre track being accessed via a wagon traverser (a section of track that could slide sideways from track to track). Powered capstans were used to shift the stock along the sidings and when the wagons and vans were unloaded they were moved to the end of the siding where the traverser moved them to the centre track. Now and then a shunting engine would collect the empties from this track without disrupting the work on the platforms.

The photo below shows the transhipment shed, dating back to the 1830s or 40s I believe, at the former goods yard on Liverpool Road in Manchester, now part of the Manchester Museum of Science and Industry. The gantry crane was used for goods arriving at and departing from Manchester itself. This yard was part of the Manchester terminus of the Liverpool and Manchester railway and most of the museum is accommodated on the site, indicating the scale of the goods operation even in the 1830s.

Fig___ Transhipment Shed and Gantry Crane in Manchester

Goods yards were busy places and most of the bays in the covered goods shed would usually be occupied. Empty carts and trailers would be seen throughout the yard, either close by the tracks ready for work or parked out of the way. The railway owned horses usually had more than one cart provided so the horse could be dealing with a collection or delivery with one whilst the other was waiting in the bay. When the mechanical horses were introduced for this work they were typically supplied with two trailers.

Some of the bays at the covered depot would be reserved for customer vehicles, allowing the use of the cranes inside the building for loading or unloading awkward items. For example McVittie & Price biscuits were shipped (in the mid 1930's) in rectangular wooden containers which were placed in open wagons and sheeted over in transit. These were too big for men to handle but the large and slow moving heavy gantry cranes would be inappropriate. Where a crane was provided by a track in the open it could be used but it was probably easier to drop it off at the shed where it could wait under cover for the wagon to become available for loading.

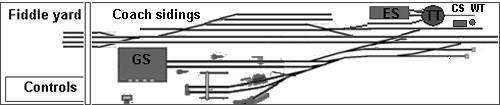

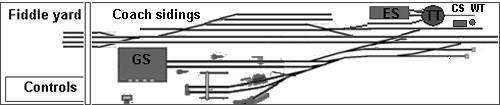

The town yard shown above required a fair bit of space, the loop has to be long enough to take the longest train that will use the yard for instance, however the detailing one can apply to a yard of this type make it (arguably) of greater interest than a passenger station. My own feeling on this is that the entrance to a large passenger station, covered by an overall roof, makes a pretty good entrance to a fiddle yard. This allows fingers to get in to uncouple engines at the head of a passenger rake inside the fiddle yard but still alows the movement of carriages from arrivals platforms to departure platforms as on the prototype. With a yard of the type shown above in the front, the main line running into the station in the middle and carriage sidings and an engine depot to the rear, I believe the overall operation of the station more closely resembles that of the prototype. This was not my idea, I first saw it in Ken Payne's book 'One Man's Railways' (published by Peco, well worth a read). The rough sketch below shows the general arrangement, this is suitable for a continuous run layout. There is a single slip allowing locos from the goods yard to access the engne shed lines from the departure road. The empty space at the front right could be occupied by, for example, a timber yard fed by a kick-back siding from the yard itself or by say a gas works fed from the main line to the right, however remember to leave hand access to the shunting loop as automatic uncouplers are never 100 percent reliable.

Fig___ Large town goods yard and carriage sidings

The larger railway companies

sometimes built a rail-served goods depot and warehouse in towns where they had

no lines themselves. The company owning the goods station would have 'running powers' allowing their engines to access the yard and received the fees for

handling at their depot and possibly local collection and delivery, leaving only the line fees for the company

operating the line to the town. This is handy as 'running powers' allow engines from other adjacent companies to appear on a layout. There were even some 'goods stations' which had

no rail connection at all, a restored Great Western Railway goods depot exists

in Liverpool close by the docks. There is no rail connection to the depot, the

goods were transported, initially by ferry and later by GWR road vehicles via the Mersey Tunnel to their northern goods station at

Birkenhead.

At Stockport south of

Manchester there were actually two large goods stations, both on the LNWR line

to Crewe and operated by that company. One was located behind the passenger

station whilst the other was separated from the passenger station by a massive

viaduct over the Mersey valley. The remote yard was mainly to serve a sundries

depot and goods warehouse operated by the company but it did possess a couple

of cranes and an open yard area for loading road vehicles. The warehouse

building is still in place and is still used as a storage warehouse. These

large multi-storey brick 'goods warehouses', offering storage facilities, would

normally only be seen in large towns or at more important junctions however.

The actual movement of goods inside the

sundries depot was very labour intensive. Each wagon had to be loaded and

unloaded by hand and the goods were generally moved about by porters with

barrows and 'sack trucks. In the later 1950's as part of their investment

program British Railways installed heavy 'slatted' conveyor belts along the

platforms in the sundries depots to move the goods but these improved

facilities were doomed to a short life as the business was effectively ended by

the 1968 Transport Act (the railways own parcels business carried on for

another twelve years, finally closing down in 1981).

Loading the wagons required some skill, for one thing the load had to be secure so it would not be thrown about in transit, for another the load had to be viewed as a whole, for example it would be inadvisable to load an anvil going to a blacksmith on top of boxes of fancy crockery going to a shop in the same town.

Before the 1930's large numbers of live

cattle came into towns to be butchered. This was done by the butchers

themselves and most towns have an area called the `shambles' where the butchery

was carried out. This entailed extensive cattle docks, usually separated from

other railway facilities and whole trains of cattle wagons were seen until the

1970's, although the traffic had been dying away since the early 1930's. This

decline was because the trains themselves offered a quick way to move freshly

killed meat into the towns, and this was cheaper and more convenient than

trying to move large numbers of live animals through the streets. Ventilated

meat vans were used for this traffic but from the mid 1930's containers

dominated this trade. The GWR used some cattle wagons freed by this process to

carry beer (marked ALE WAGON) or converted them to ventilated fruit vans. This

latter move was so successful that the LNER and the GWR actually built such

fruit vans as new in the late 30's.

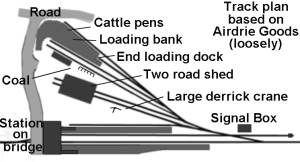

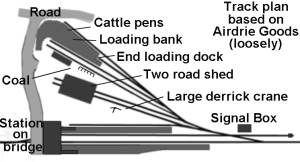

Suburban and Country Station Goods Facilities

Out in the country the same basic handling facilities would be required, however the land was cheaper so the yards tended to be quite large, particularly where the station was close by an industrial area. The example shown is (very loosely) based on Airdrie Goods, a former one-platform terminus on a single track ex Caledonian line. On the prototype there were two more sidings between the loading bank and goods shed, these were used for coal traffic, there was also a second spur feeding another end loading bay at the end of the loading bank. No engine facilities were provided at this site and no shunting engine appears to have been stationed there.

Fig___ Rural goods yard close by an industrial area

Further out into the country the same basic facilities would be required albeit on a much smaller scale. A raised platform or

'loading bank' was provided in almost every yard to ease the loading and

unloading of railway wagons. Wagons or vans run into this siding might still be

emptied directly into a road vehicle pulled up on the other side of the tracks.

A 'loading gauge' (as discussed in the section on

Track - Gauge & Loading Gauge) would usually be provided to check loaded

wagons before they were allowed to travel.

Almost all yards would boast a goods shed,

with railway access on one side and often a road vehicle loading bay on the

opposite side. In many cases the loading bank was entirely confined within the

goods shed but some stations had an outside platform as well, either extending beyond the shed or entirely separate from it. In real life stations were as often as not built on a very

slight curve, but for model purposes keep curves as gentle as possible where

any form of automatic uncoupling will be used.

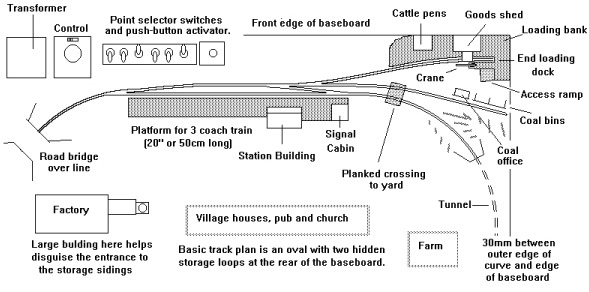

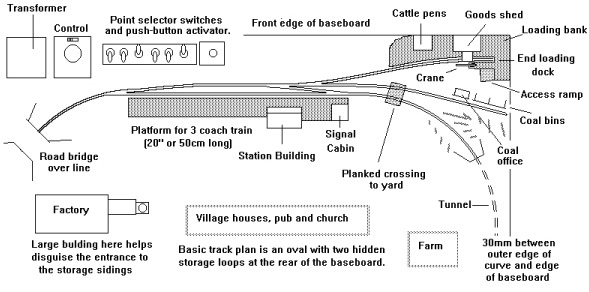

Fig ___ Very Small Goods Yard

The layout in Fig ___ is one I included in a very small

portable layout built some years ago. The radius of the curve at either side of

the main line at the front of the layout is only twelve inches. I used a

right-handed twelve inch radius point (I seem to remember this was of American

manufacture) on the left to increase the size of the run-round loop. The lack

of space in the goods yard area restricted the number of vehicles the yard

could handle at any one time but most kinds of traffic could be justified. The

yard includes all the above mentioned features; access in the open for loading

directly on to road vehicles, a raised loading bank with a crane, a small goods

shed, cattle pens and an end-loading dock. There is also a separate siding for

the local coal merchant. The curves at the rear were nine inch radius Peco 'set

track' with two points at either end to provide the storage loops. The

baseboard was about four foot by two foot six inches, it had a thin plywood top

on a one inch by one inch timber 'ladder' frame (giving sufficient depth for

the point motors). The profile boards at the front and sides and the false

back-scene in front of the storage loops were cut from hardboard. There was a

hardboard bottom on the underside of the baseboard for rigidity, held with

screws so it could be removed for repairs to the wiring. Strips of felt were

added to the hardboard sheet using double-sided tape so it would not scratch

the dining room table. The goods shed started life as a Peco kit, I replaced

the walls with 'stone' embossed plastic card, reduced in height to sit on the

loading bank and used only the roof, window and front valence from the kit.

Goods Handling Equipment

Mechanisation was

rather more common in the larger yards. Steam powered cranes might be seen and

I have found (in an old (1930's) school book) a picture of a portable conveyor

belt, apparently electrically powered, being used to lift sacks into open

wagons in a goods yard. The picture would appear to date from the 1920's as the

wagons are all in `pre-grouping' liveries. Something similar is the `farm

elevator' available in `N' from the Fleetline range of cast whitemetal items

but this is a little wider than the example in the photograph.

Fig___

Portable conveyor used in a goods yard

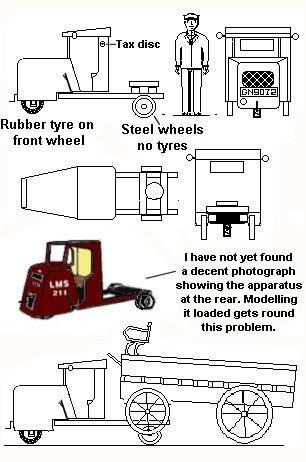

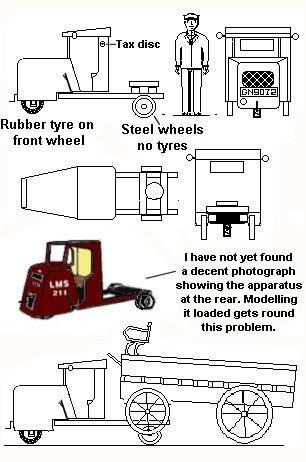

The petrol lorry was starting to appear in

railway company service by the 1920's but horse drawn transport remained in

service at many stations into the 1950's. One distinctive design was the 'Cob'

(named after a type of working horse) first built in 1930 by Karrier in

Huddersfield. This was a tiny three wheeled truck designed to pull horse drawn

wagons, later versions included the option for a purpose built semi-trailer. It

had a rubber tyred front wheel but the rear wheels were simple steel types with

no rubber tyre. These were slow machines by modern standards but they had a

very small turning circle, they were reliable and economical and they could

pull substantial loads about the place. The Cob proved popular with railway

companies and industries such as gas works. As far as I am aware the Cob was

only used inside the goods yards, not on the roads, but I understand they

remained in use into the 1960's.

Fig___

Karrier Cob

The advantages of

a three wheeler delivery tractor saw a range of such machines being developed,

some of which remained in use into the early 1970's. More information on the

many three wheeled trucks used by the railways will be found in the section on

Railway Company Goods Facilities - Railway Owned Road Vehicles

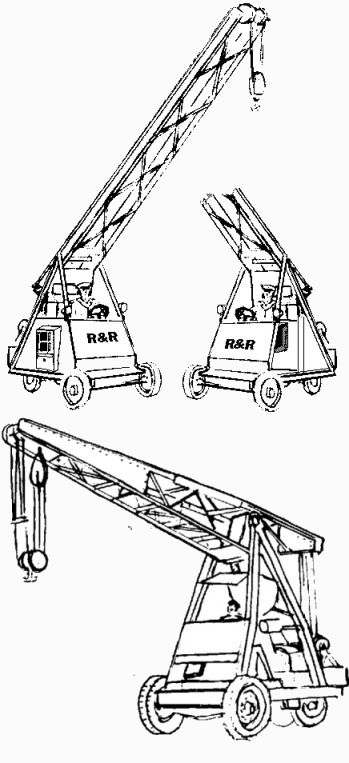

Fixed crane design is discussed more fully in

the section on Wagon Loads & Materials Handling - Materials Handling - Hoists and Cranes but the railway companies also used

self propelled mobile cranes in goods yards. These small cranes had

lifting capacities up to about three tons and could lift large or heavy loads

such as containers on or off the wagons and move them about the yard. I have

seen photographs of these cranes as early as the mid 1930's. A model could be

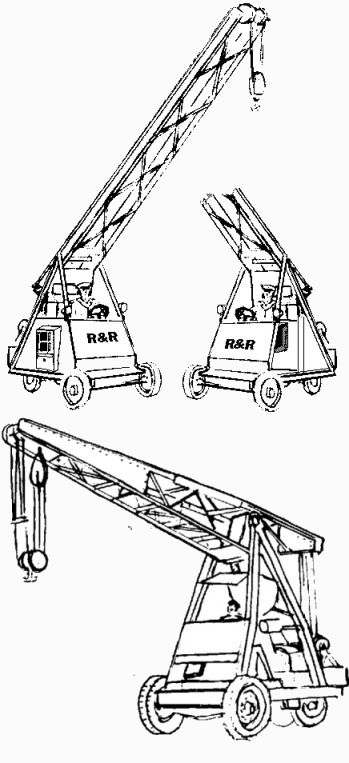

produced from plasticard and strip.

The

most easily modelled design had two 'A' frames with the simple cab and engine

between them although the jib would be rather fragile in this scale. The jib

consists of two lengths of `H' section, a maximum of 1mm deep, with cross

trussing from paper or microstrip glued between them. The pulley wheels at

either end and the wire drum can be cut from the end of a small diameter metal

bolt. Five amp fuse wire, or a single strand from multi-core layout wire, would

serve for the lifting rope.

Wheels for the crane can be made

from short lengths sliced from some electrical wire sleeving and packed with

Milliput. An alternative for the crane would be to use the Knightwing fork lift

truck as a basis, adding simple A frames and jib as above. This basic design

was used for cranes of various sizes, the lower illustration shows a heavier

type, the job for this can be made up using the Ratio OO scale 'LNER Signals

Set' which includes a number of lattice masts that serve well in N for crane

jibs.

Fig ___ Small mobile cranes

After

the war BR used a number of ex-military petrol powered cranes mounted on the

rear of short wheelbase lorries, these were commonly used to lift the

pre-speedfreight old style containers on and off Conflat wagons. The Airfix

'recovery set' includes one of these cranes suitable for use on an OO layout.

A common design seen on British Railways after the mid 1950's was a small four wheeled crane with a long lattice jib fitted to a rotating upper body. These were used for a wide range of work including container handling and could be fitted with a grab to handle coal and coke. The same basic design, fitted with a shorter jib, was used by the Permanent Way staff although these tended to have double wheels to cope with driving about on the ballast and rough ground beside the line.

Fig ___ Small Coles mobile crane as used by BR

Some larger goods yards (and some

industrial locations) were equipped with a gantry crane, examples of these are

available from the Continental firms and Knightwing the new British whitemetal

model range includes such an item. Some care is required in selecting which

type is most suited to ones period. One of the continental models is of a

rather modern tubular metal design, only suitable for use in layouts set after

the late 1960's and most are of the fixed type whereas a more common

arrangement in Britain is to have a mobile system. Mobile types were of two

kinds either with the supporting end frames mounted on rails set into the

ground or a raised gantry on either side of a set of sidings along which the

crane travels.

On occasion there might be a flow

of unusually heavy traffic to a smaller goods yard, for example building materials being shipped for a

local construction job. In such a case it was not unusual to provide an

additional rail crane (a crane mounted on a railway wagon), usually hand

operated. It was not uncommon for this crane to be placed on a specially laid

section of track, the siding would be broken and the end slewed off to one

side. A short length of track would be bolted on (perhaps 2 inches in N scale)

and the crane would be parked on this new section. The original track would

then be dragged back into line and reconnected to the rest of the siding. The

wagons would run into the siding and the crane could be used to transfer the

materials to wagons or lorries.

A steam

crane might be sent if the traffic included quantities of heavy materials, but

this was much less likely in a country yard and these were rather heavy and

expensive for parking on temporary lengths of track.

Shunters Trucks

Something not often seen modelled, but a part of any

large goods yard or marshaling yard up to the 1970's on ex Great Western or LMS lines and in many

industrial private railway systems, is the `shunters truck'. This was a small

open flat wagon generally fitted with running boards as seen on brake vans and

grab handles for the shunters to ride on. Mounted on this there was often a box

to hold tools, usually with a simple metal rack on top to carry the poles. This

box was definitely used on the GWR types, which were very standardised, the LMS

standard design had no box but yard staff might well add one for their

convenience.

A GWR version is available as

a kit from P. D. Marsh, adapted to fit the Peco 10 foot wheelbase brake van

chassis. Technically this should have a 7 ft. wheel base, which requires some

butchery. I built one by cutting down a Peco brake van chassis and fitting a

cut-down single bolster wagon body on which I added the tool box from a block

of Milliput and handrails from fine wire. The LMS type could be made up using a

P. D. Marsh one plank open wagon kit on a Peco ten foot brake van chassis with

handrails from fine wire. You could make one by carving the unwanted swivel and

floor detail from a Peco single plank bolster wagon body but again you would

need the brake van chassis.

Fig ___ Home made GWR shunters truck

Changing to metal tyred wheels offers the possibility

of taking extra electrical pick-ups to be linked permanently to a short wheel

base shunting locomotive. I used mine with a Pannier 'dock tank' kit, built using a Minitrix chassis. Some thing similar was used on the real railway, where `track circuiting' is used the small class 03

diesel locos on BR often have such a wagon permanently attached to help ensure

the circuit is completed as the train passes over the section. On the western

region old GWR shunters trucks were used, on Eastern Region they used what

appear to be redundant Conflat wagons.

The Post Beeching Era & Facilities for Air Braked

Services

In the mid 1960's the

less-than-wagonload 'sundries' depots were cut back to less than a hundred in

the whole country. Before this time most towns had several sundries depots,

originally built by the competing pre-grouping railways in the late 19th and

early 20th century. In 1968 British Railways were finally released from their

common carriers obligation and the loss making sundries business was handed

over to National Freight Carriers, the nationalised road haulage service. This

brought the end to the last of the town and country goods yards although goods

shipped by the wagon load continued to operate in a limited way.

Where the shipper or recipient did not have

a direct rail link these full wagon loads could be handled at a single siding

and in yards up and down the country odd sidings were retained for this

traffic. In the mid 1970's there was a move to recapture the wagon load traffic

and this was backed by investment in new high speed air braked rolling stock.

These wagon load services operated in the main between private sidings but

there were a number of public terminals established to provide road collection

and delivery. The railway owned many of the terminals but an equal number were

operated by distribution organisations such as Isis Link.

The facilities offered at these terminals varied depending on

the nature of the traffic to be handled, a single siding which received the

occasional van load of fertilisers would have only a concrete area for the

lorry to pull up alongside or for a fork lift to operate. In terminals where

containers were handled, these could be ISO types (although this was and is

rare) or the special containers used for coal and potash, the usual container

handling equipment is a large fork-lift type vehicle, either with hefty forks

or with a top-attaching lifting frame. Some terminals offered covered

warehousing but this was not common, they were mainly geared toward

transhipment from rail to road for onward delivery. Examples of terminals from

the Speedlink era have been sketched in Fig ___ in the section on Freight

Operations - Air Braked Network, Speedlink and Enterprise wagon load services.

Some traffic required special handling, a

good example being the bulk grain being delivered to yards by the Grainflow

service. Some of the grain was loaded at or delivered to purpose built grain

terminals and these are considered in Volume 2, some however was delivered to a

simple open yard where it was transferred to road vehicles for final delivery.

The hopper wagons discharge through the bottom but under track bays for lorries

would cost too much to build. The answer was to build a small pit under the

track into which an portable electrical auger can be positioned to transfer the

grain into the lorries (see Railway Freight Operations - Grain and Beer Traffic)

.

Following privatisation the

land and other property owned by the British Railways Board was divided between

Railtrack and a new organisation called Rail Property Limited. Basically

Railtrack got anything which was in actual use or which the Government felt

might be used and all the rest went to RPL to be sold off. In the event

aggressive marketing by EWS has seen an increase in smaller volume freight

flows and between 1994 and 1998 over seventy of the mothballed freight sites

were reopened for business. Railtrack has had to buy several sites back from

RPL, in at least one instance competing with a bid from a major supermarket

chain, and eight of these sites are being redeveloped for freight. As the

nature of freight traffic flows has changed Railtrack have also been looking

for new sites with no previous railway connection. They see a need for several

terminals in the South East and have already purchased land for freight

operations in the Birmingham area and along the East Coast Main Line.

By 1998 there were about a thousand freight

terminals of all kinds operated by a number of rail and haulage companies with

a further seven hundred mothballed and another dozen or so new sites being

developed.

^

Go to top of page

International Good Guys ~ Making the world a

better place since 1971 ~ Site maintained by

All material Copyright © Mike

Smith 2003 unless otherwise credited