Milk - Dairies and Creameries

For more information on the railway side of the milk business see Freight Operations - Non Passenger Coaching Stock - Milk.

For more information on milk deliveries see Appendix One - Civic and Commercial Life, Public Buildings, Shops, Traders and Tradesmen - Traders delivery vehicles and mobile shops .

For a good overview of the whole business of supplying milk to the towns

a visit to the National Dairy Museum, Wellington Country Park, Riselley,

Reading RG1 3OH (Tel: 01734 390918) is worth considering.

Outline History

Cows produce milk twice a day, sometimes three times a day in high season and this has to be distributed fairly quickly. Prior to the 1870's milk was supplied by cows raised in the towns or on open land close by, the railways carried some milk into the larger towns from the early 1830's but in the latter part of the 19th century there were still large herds kept in cities such as London to provide milk for the inhabitants. The milk was generally of rather poor quality and it was distributed in pails or buckets carried in pairs on a shoulder yoke. The galvanised iron milk churn was introduced from the USA in the 1850's and soon replaced the 'pail' although this required a wheeled vehicle to carry it. An outbreak of rindepest in London in the 1870's precipitated a crisis in milk supplies, prompting an entrepreneur by the name of Barham to set up a railway based supply from country areas in 1871. He called his enterprise Express Dairies to emphasise the railway connection which was at the time rather trendy and 'high tech'. This business was a great success and other firms established country depots to collect milk from farms, sending the milk to the town dairies by rail. This was followed by various other milk marketing organisations, often local co-operatives operated by farmers. The other large companies involved in rail supplied milk included United

Dairies (formed by a merger of Metropolitan and Great Western Dairies, the Wiltshire United Dairies and The Dairy Supply Company in 1917), Independent Milk Supplies and of course the Co-Op. In 1959 United Dairies merged with Cow and Gate to form Unigate although both prior names remained in use.

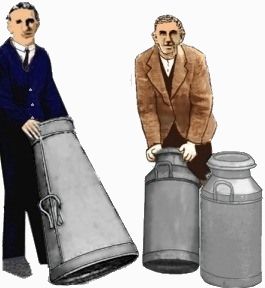

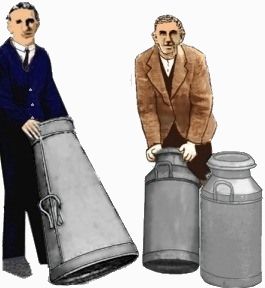

Milk was originally distributed in 'pails', buckets (I believe they had lids), the vendor (in the country this was often a farmers wife, hence 'milk maid') carried two of these on either end of a wooden yoke. Customers would bring out their milk jugs and the vendor would use a ladle to dispense the milk. Once the railways started carrying milk the pail proved less than ideal as it was top-heavy and tended to spill. The farmers used a tall conical wooden container to 'churn' the milk to make butter, this was made up of staves bound with metal hoops (technically a 'cask') and this proved to be preferable for the railways to transport. It held a lot more milk (about seventeen gallons) and its conical shape made it less likely to spill or fall over. These wooden churns were intrinsically heavy however and from the 1850's a steel version was introduced from America and soon became the standard. The name churn was retained for these containers (the Americans called them 'cans') although they were not used for making butter.

The milk churn was a standard size, the older galvanised iron conical type held 17 gallons, the cylindrical type with the mushroom shaped lid introduced in the 1930's held ten gallons. Each churn carried a brass plate near the top to identify the owning company and when full it would have a white paper label (tied to the handle on the lid of the conical type and to the side handle of the cylindrical type), which was used for accounting purposes by the creamery or dairy.

Milk churns were heavy so the normal practice was to tilt them on one side and roll them along, the sketch shows both the older conical churn and the later cylindrical type being moved in this way.

Fig___ Milk churns

The milk churns were loaded into the milk vans from the station platforms, a farm hand assisting a porter was the normal practice. On the platform they often sat in the shade on small 4 wheeled trolleys, such as those offered in the old Triang Trebleo-Lectric figure sets. These sets are still occasionally being marketed, although presumably old stock. Note the loaded churns would all have a white paper label attached to one of the handles. By 1883 one farmer alone was sending 19,000 gallons a year to Birmingham and by the late 1880's entire trains of milk churn vans were a feature of railway operations.

The milk churns remained part of the railway scene into the 1960's, possibly the 1970's, bringing the milk from the farms to the country dairy and also travelling to the smaller towns and communities along the line. Milk churns remained the principal method of collecting milk from farms for many years. In about 1966 the MMB pressed farmers to invest in cooling vats and bulk handling equipment and by the mid 1970's most milk was being collected from farms in road tanker lorries. The last churn collection by the England and Wales Milk Marketing Board (by lorry for road delivery) was in 1979, I am not sure when the Scottish MMB (always a separate organisation) ceased accepting churns.

All the four Pre-Nationalisation companies carried milk traffic, the GWR had the largest share, followed by the LMS then the Southern, serving areas of Somerset and Devon and the Somerset & Dorset line. The LNER carried the smallest share, mainly milk produced in East Anglia.

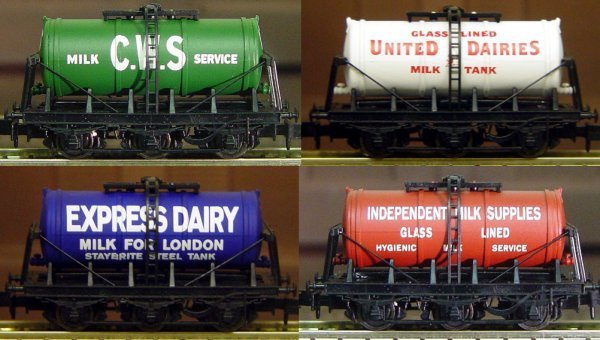

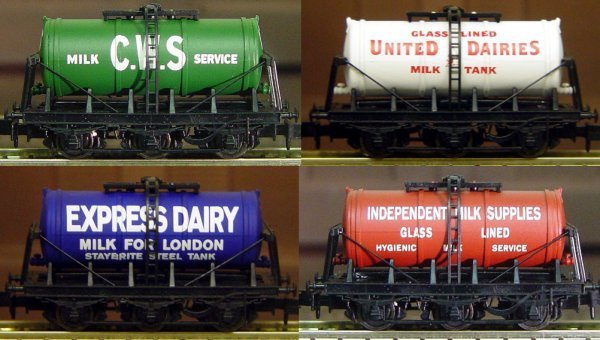

In the late 1920's there was a change in the way milk was handled by rail with the introduction of insulated 3,000 gallon rail tanks to supply milk to the larger towns. The LNER estimated that a small fleet of seven tanks they provided for Express Dairies replaced over two thousand churns on the run to London. A single tank wagon would supply enough milk for some 35,000 people so smaller towns continued to be supplied with churns up to the end of the Second World War. Rail and road/rail milk tank wagons and their liveries are considered in greater detail in the separate section Freight Operations - Non Passenger Coaching Stock - Milk. Peco offer a model of the pre-1937 four wheel tank type, Dapol offer a model of the post-1937 six wheelers. The picture below, courtesy and copyright Dapol, shows a selection of their 6-wheeled milk tank wagons in N.

Fig___ Milk Tanks by Dapol

These tanks were not filled at the farm, they operated from country 'Creameries' where the milk, collected from farms in churns, was processed and sent to town 'Dairies' from where the milk was delivered to homes and businesses. Dairies and creameries are popular with railway modellers as they allow the use of interesting rolling stock, notably slat sided milk churn vans and six wheeled milk tank wagons.

The Milk Marketing Board (MMB) had been set up in 1933 to ensure supplies of affordable milk were

available throughout the country. The MMB bought all the milk from the suppliers and sold it on at a standard price to retailers. By 1948 the MMB was collecting milk from 130,000 farmers, using some 500,000 ten gallon milk churns and delivering to about 10,000 destinations, mainly dairies but also chocolate factories, dried milk factories and other users. Rationalisation reduced the number of individual consumer locations supplied to 496 by 1972. Pressure from the MMB meant that by the end of that decade the once commonplace churns had disappeared, replaced by bulk handling and chilling equipment on the farms.

The quantity of milk moved by rail has fallen steadily over the years, from 282 million gallons in 1923 to 230 million gallons in 1929 and by 1969 there were only two major milk runs of two trains a day in regular operation, one from Fishguard the other from Devon & Cornwall, all destined for London. It is worth noting however that this was

still some 70 million gallons and accounted for some 25 per cent of the total milk moved. This contract was finally lost in May 1980, and the trade is now carried entirely by fleets of road tankers. In the later 1980's I contacted the MMB who told me they had a fleet of rail tank wagons in reserve but rail transport was only used when milk had to be moved a great distance (milk is only moved 70 to 100 miles by road), or when road transport presents difficulties such as in bad winters. As far as I am aware the road-rail tanks fell out of use in the 1960's.

For the purposes of the following discussion dairies are establishments located in or close by towns where milk is processed and bottled for local delivery. Creameries were built in country areas after the 1870's, they process the raw milk from the farms and ship the milk, cream, butter and cheese to the towns. These two ends of the railway side of the business were very different in appearance and need to be treated separately. There were also other users of milk supplies, butter, condensed milk and cheese factories all required regular supplies. These peripheral industries are considered at the end of this section.

Dairies

Dairies sold and distributed milk and related products, up to the later 19th century they often operated in-town cow sheds or dairy herds kept on small fields in the towns. This meant a lot of the milk was contaminated and disease was a problem for both the animals and the dairies customers. The railways were used to bring milk into town from the country from the earliest days but following an outbreak of disease in the London herds Express Dairies was set up in 1871, who chose their name to emphasis the railway connection, to bring milk in metal churns from dairy farms in the country to town dairies. Other firms followed and most large towns received regular supplies of milk in churns via the railways. Up to the Second World War most milk was sold raw, that is it was not 'pasteurised'. There had been a continuing development of milk production since the mid 19th century and by the end of that century there were techniques such as filtering and 'medication' in use. Dairies supplying milk using these methods often had the word hygienic in their name, however the milk once processed was still delivered in churns. With the development of rail supplies the processing of the milk was moved into the countryside where dedicated 'creameries' were built in some numbers. These creameries were capital intensive and were usually built by the larger town dairy firms however there was a financial recession in progress at the time and there were a number of mergers forming larger concerns able to afford such an investment.

In town dairies were simple affairs in the early 19th century, the milks was delivered from churns with a ladle to fill customers milk jugs and a couple of shops selling milk and often other dairy or farm produce. The introduction of rail-bourn milk prompted the establishment of larger establishments. Most of the rail connected town dairies were built when milk was moved in churns and would feature long platforms. By the 1930s as milk tanks became increasingly common the new dairies would require a smaller siding to accommodate the tanks (and perhaps a siphon or couple of long wheelbase passenger rated vans for associated produce). In a discussion on milk traffic on the uk.railways newsgroup Brian Williams was able to advise - Regarding the unloading end of things, most terminals (Merton, Cricklewood etc) were simple private sidings. However, one notable exception was the dairy at Vauxhall, the first station after Waterloo- here the wagons were stopped on one of the platforms, and hoses connected to them- the pipes disappeared below the platforms- I can imagine the environmental health and HSE people would throw a wobbly if someone proposed this today- third-rail electrification, pipes trailing everywhere etc.

The dairies I remember were all fairly low affairs, typically two storey buildings with quite a lot being single storey. One I remember was located in a town and the ground floor was where the milk floats resided, the upper floor being associated with offices and the bottling plant. The architecture was very varies and I do not recall any really distinctive features.

From the dairy the milk was distributed to customers ranging from doorstep deliveries to individual homes to larger deliveries of churns or road-rail tanks going to industrial users. Domestic deliveries accounted for a great deal of the output of town dairies right into the 1980s. The domestic delivery vehicles, ranging from hand pushed perambulators to electric milk floats, are discussed in detail in Appendix One under 'Traders delivery vehicles and mobile shops'. Any dairy benefits from having several delivery vehicles on view to help set the scene, although during the morning hours most of these would be out on their rounds.

In the very early days milk was carried in buckets or pails on a wooden yoke, an image which is even today associated with milk products. A single person (the term milk maid is widely associated with this work but men were often employed) could deliver perhaps 20 gallons a day, measuring the milk using a metal ladle on a long handle. Perambulators were introduced 1860 which enabled a man to deliver the milk from town dairies in churns instead of pails on a yoke, this meant he could distribute 30 gals per day. Simple perambulators were in use well into the 1930s, with the electric type coming in the early 1930s. In some areas horse drawn floats were used to establish the trade but replaced by the more economical man powered perambulators once the custom was established, this was still happening after the First World War. The problem is that few people would recognise a perambulator so the horse drawn float is possibly a better option for a model. Early milk floats were simple two wheeled carts designed to carry one or two churns, the term float actually means any low-floored vehicle, the low floor making it easier to load the full churns. These had large wheels, say four or five foot in diameter but mounted on a U shaped ('cranked') axle, allowing a lower than normal floor on which the churn was carried. People went out with their milk jugs to collect a pint, measured out with a long handled tubular metal ladle (see Fig ___)

Bottled milk first appeared in the 1880s, the earliest reference I have found quotes their introduction as 1880 by Express Dairies, another claims it was 1884 in Northern Ireland and several references quote 1900 for England, this being for pasteurised milk only. The bottle making process was only partly automated at that time, fully automatic bottle making was developed by an Irishman called Michael Owens in 1903 and this provided the impetus for the rapid expansion of the bottled milk market. Bottled milk required a substantial investment in plant so it was mainly associated with large towns well into the 1930s. Milk was bottled at the dairy, this did not initially involve complex machinery, the bottling was originally done by hand and the bottles were marked 'This package is sold as a bottle of milk not a measured quantity'. The bottles were sealed with a cardboard disk that popped into a groove on the inside of the top of the bottle. Some dairies opted for a porcelain stopper, fitted with a rubber washer to seal it and held on with wire. The foil top, which appeared in the early 1930s, replaced the cardboard and porcelain stoppers as it was more hygienic as there was no 'well' at the top of the bottle to collect dirt. By the 1940s simple bottle filling machines were cheap enough for these small dairies to use, but the tops were still put on by hand. In the 1930s and 40s there were several different sizes of bottle, half pint, pint, one and a half pint and two pint, but by the later 1950s only the one pint type were in general use.

In town milk bottles were increasingly seen from the early 1920s (it was introduced in Manchester in 1926) and became commonplace from about 1930. The milk bottle prompted the introduction of horse drawn milk vans to carry the crates of bottles. A 'float' is technically a low floored vehicle and these vans had a normal height floor, however the tradition was to supply milk from churns carried on a float so the public called them 'milk floats'. By the mid 1930's pneumatic tyred horse drawn milk floats were being built with a central bay for the driver and horse drawn milk floats were being built as recently as the 1950's. A horse drawn milk float was still in use in South Manchester in the late 1980's.

For more information on horse drawn milk floats see the small Shire Publications book 'Discovering Horse Drawn Commercial Vehicles', detailed in the bibliography. The National Dairy Museum (details above) holds a collection including examples of perambulators and floats.

By the 1930s electrically powered floats and perambulators designed to carry light wooden and later metal crates of bottles were in use. The electric vehicles were common in towns by the later 1930's but horse drawn milk floats remained in widespread use (one was still in use in South Manchester in the late 1980's). Electric milk floats are easier than the horse drawn floats to model, the only problem being that they favoured small pneumatic tyred wheels.

Milk floats of various kinds are illustrated and discussed in Appendix One under 'Traders 'Rounds', delivery vehicles and mobile shops'

Creameries or Dairy Factories

Creameries were located in country areas, usually beside a main line to allow fast transit to the town(s) being served. The first rail connected milk collection depot at Semley in Wiltshire opened in 1871 alongside the LSWR main line. This was the first wholesale milk depot built to supply London. Dairy factories proliferated in the 1870's and in the latter part of that decade a centrifugal device for separating cream from the milk was developed by Carl de Laval and L. C. Nielson which lead to the term 'creamery' for establishments where this was used. As an example of the range of products made in these country factories the Culm Valley Dairy Company plant at Hemyock in Devon opened in 1886 mainly to produce cheese and butter. The plant also supplied churns of raw milk to London dairies and bottling plants, kept pigs (which they fed on the unwanted 'whey' from the milk) and was involved in the development of spray drying processes. Spray drying to produce powdered milk was developed before WW2, this required new buildings, typically five stories tall, to house the equipment. After the war these tall buildings were used to make instant coffee, which became a roaring success and instant tea, which never really caught on.

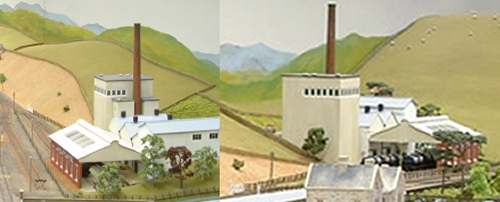

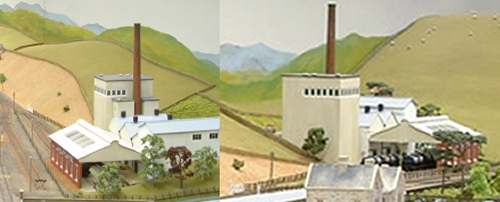

The picture below shows two views of the large creamery on the late Andy Calvert's Moorcock Junction layout, set in the 1950s-60s era. The tall building is characteristic of a powdered milk facility, which justifies regular van traffic.

Fig___ Country creamery on Moorcock Junction layout

Photo taken at the N Gauge Society 35thth anniversary exhibition, reproduced courtesy and copyright

N Gauge Society and Bob Harris, the current owner of the layout.

Creamery buildings ranged from the distinctly rustic, light timber construction often with corrugated iron roofs, through a range of more elaborate designs to the classic 1930s 'streamlined' concrete. The size and number of buildings was also very varied, although most purpose built creameries favoured single storey industrial (similar in height to a two storey house) some had a taller building with two or three floors (notably where factories and mills were converted for use as a creamery.

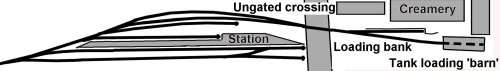

The sketch below is based on the Express Dairies creamery beside the Settle and Carslile line (from a photo taken just after the Second World War). The track plan is simple, a single spur that opens into two sidings passing a loading bank (long enough to accommodate a single bogie milk van) and into a loading shed (make this long enough for at least three tank wagons, I believe the prototype held five on each track). Note the soot stains on the canopy, indicating that engines passed under the shed (apparently more so on the creamery side as the staining there is darker). Extending one of the sidings to beyond the shed would give somewhere to park some coal wagons for the boilers. One point to note is that these establishments were painted with green and black camouflage patterns during the war, many of which remained in evidence into the early 1960s.

Fig___ Country Creamery

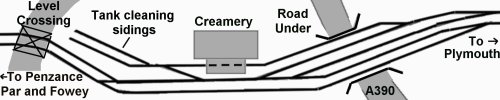

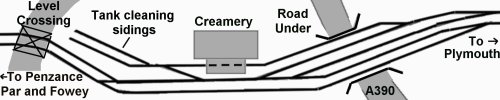

Not all creameries were so tidily arranged, the establishment at Ecton on the Leek & Manifold Light Railway was on a narrow gauge line but still handled the bulk milk tanks, transported on special transporter wagons (I believe the standard gauge milk tanks were four wheelers right into the late 1930s, presumably constrained by the design of the transporter wagons, but I could be wrong on that). The example below is based on Lostwithiel, I believe milk tank trains would arrive and depart on the line to Plymouth although the track plan baffles me. This site features two separate sidings used (I believe) for steam cleaning the milk tanks prior to loading, a smelly operation by all accounts. These would have either a single raised walk-way between the lines or one for each siding (having said which I have seen a photo showing a single walkway beside two sidings, access to the tanks on the far side would be either via the tank side ladder or via a plank laid across the tops of the tanks). I gather Lostwithiel passenger station was on the far side of the level crossings, which must have been a bit smelly if the wind was from the east.

Fig___ Creamery with complex rail connection

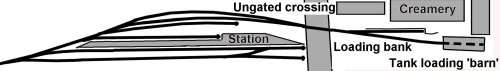

Some creameries had only a single siding, the sketch below is based (loosely) on Heymock (GWR) where the creamery was accessed via a siding crossing the road beyond the small terminus station. The sketch has been altered from the prototype to provide more varied working on a layout, the original loading bank (once used for churn traffic) now serves for loading butter. Most creameries seemed to arrange for a covered area to load the milk tanks, these ranged from solidly built structures such as that shown above to a simple corrugated iron 'Dutch barn' structure, often located a short distance from the creamery buildings (possibly because of the smell of the steam cleaning of the tanks).

Fig___ Creamery beyond the terminus on a branch line

With such diverse architecture there are few characteristic features of a creamery, however all had a loading bay where the milk brought in in churns could be decanted into the system for processing. The sketch below is based on a photo of such a bay in the cobbled yard of a creamery in the 1950s. The driver of the lorry (with a uniform cap and ID badge on his light brown cotton summer jacket) is lifting down the churns (note the rubber hose on the retaining chains on the lorry) and a worker from the creamery is pouring them into the large metal hopper. I have no idea why there is a pipe at the top of the hopper but it looks impressive.

Fig___ Creamery receiving bay

Note that at the country creamery there would be large numbers of milk churns, these were the main method of transporting milk from the farms up to the mid 1970's. Larger towns were increasingly supplied by rail tank wagons from the 1930's but churn vans were still used to carry other milk products even when all the milk was shipped in bulk. When considering traffic to the dairy or creamery do not forget the occasional wagon load of coal for the boiler and the odd van or open wagon delivering equipment and chemicals.

Butter was one of the main products of the creameries and some establishments were set up with this as their primary purpose. The Co-Operative Wholesale Society, after being involved in Irish creameries to obtain butter for English markets from the 1860's opened a chain of butter producing creameries in England and Wales in the 1880's. These factories were conveniently easy to letter, the sign outside would usually say simply 'C.W.S. Butter Factory'.

One oddity of the milk trade was the problem of disposing of the whey from the milk and with the introduction of the country creamery one solution was to set up pig farms and feed the whey to the pigs. The larger creameries and dairies quite often had a slaughterhouse and associated 'bacon factory' to cure bacon or can the pork. The resulting pork and bacon would then form traffic for the local goods yard (as far as I am aware the meat was not handled at the creamery siding but I could be wrong on that point). Since the later 1970s the whey is often used to make 'instant mashed potato'.

Pasteurised milk was developed in the 1890's but even in the late 1930's a lot of milk was sold 'raw' and had to be boiled to make it safe to drink. Pasteurisation has nothing to do with 'pastures', it is a process named after its inventor Louis Pasteur, the chap who also invented vaccinations. In pasteurisation the milk is heated to kill bacteria, it is a valuable protection against various disease carried by cattle that can infect people. One problem was determining the time and temperatures required, if these are wrong it starts the spoiling process in the milk. Modern practice uses temperatures of between 80 and 88 degrees centigrade maintained for a period of between 20 and 40 seconds, this is called 'flash pasteurisation'. Sterilised milk is heated at higher temperatures and greater pressure for a longer time.

Long Life or UHT milk (UHT = Ultra Heat Treated) was invented in 1965 and when coupled with the paper and plastic tetrrahedron shaped 'Tetra-Pak' container made milk vending machines a viable proposition. These machines had a blue body with a convex translucent illuminated white front, the word Milk was printed on the white panel in blue lettering, they were quite common up to the mid 1970's.

The milk vending machines casings were made of fairly thin sheet steel or aluminium and were designed to be weather-proof, older machines were built from heavy metal castings to resist both weather and theft. Vending machines were much more common in years past, they seem to have all but disappeared since the 1980's with the growth of vandalism.

Condensed milk factories

Condensed milk came with the 'vacuum pan' patented by the American Gail Borden in 1856 and developed in the USA during their Civil War. The first condensed milk factory in Britain was at Chippenham where a two storey woollen mill built of grey limestone was converted to this use in 1872. The new owners were the 'Anglo-Swiss Condensed Milk Company' which had been set up in Switzerland in the 1860's by two Americans brothers called Page. They produced the milk and exported to several countries including Britain. Also in Switzerland Mr. Henri Nestle began making a milk based baby food in the 1860's and he followed the Anglo Swiss move into Britain. A degree of competition arose when the Page's produced baby food and Nestle made condensed milk, the two concerns merged in 1905.

The factories were seldom phtographed however they were in the main brick-built structures, typically two or three storey and from the 1930s the flat metal-strip window frames seem to have been preferred.

Cheese factories

Butter and cheese were made on the farm to be sold locally, although particularly in the case of cheese the goods could be shipped some distance. The Americans developed mechanised or at least bulk production of cheese and the cheese factory at Longford in Derbyshire was the first in Britain built to use the so called 'American process' for production of cheddar cheese. This is a fairly simple single storey building with brick side walls and weather boarded ends. The larger dairy companies, with their country creameries, branched out into cheese making, using the railways to carry the cheese into the towns.

Ice Cream factories

Ice cream was made at home from about the Victorian era but a company called Walls started selling the stuff commercially at about the time of the First World War. In 1922 they purchased a tricycle with an insulated box on the front and started selling on the streets, this was a success and by the time of the Second World War the Walls 'trike' with its Stop me and buy one logo, was a familiar sight all over England operating from over a hundred depots round the country. See also Appendix One - Street traders, hawkers and buskers for illustrations of ice cream trikes. Walls built the worlds biggest ice cream factory in Gloucester. In 1981 Walls merged with Birds Eye Foods.

An ice cream factory in a town would be a likely candidate for a road-rail milk tank trailer delivery, I do not know of one with a dedicated railway siding (although there may have been such).

The Milk Marketing Board (MMB)

The MMB was set up in 1933 to act as a buffer between the farmers producing milk and the dairy companies selling it, there were actually a total of five MMBs set up but I am unsure as to the details and they all seem to have used MMB as their logo. At that time it was still felt necessary for the country to retain a degree of self sufficiency and the government wanted to maintain both the farms and the dairies in the face of the world wide depression. The MMB had the right to purchase all the raw milk from the farms, giving them a secure market to supply and the duty to find a market for it. The prices at which the MMB sold the raw milk varied according to end use and were decided by a Joint Committee in which buyers have an equal say with MMB, any disagreements being settled by arbitration. For a given end use the price is the same to virtually all buyers, preventing the bigger firms putting the smaller concerns out of business.

The MMB itself owned facilities for processing liquid milk and for manufacturing milk products (such as butter and cheese), these were in effect commercial operations, as distinct from its statutory functions in relation to raw milk. The legislation required the MMB to treat its commercial operations on an equal footing with independent milk buyers and not to give its own operations any preferential treatment. Legislation was enacted to set the maximum and minimum price at which milk could be sold. During World War Two the MMB took over responsibility for transporting the milk, repainting the railway milk tanks in MMB livery.

In the later 1980s the government decided this orderly state of affairs was not conducive to competition, apparently they were still unaware of the power the supermarkets wielded, so the MMBs were wound up and a free for all ensued. Within twenty years the actual result was to drive many British dairy farmers and town dairies out of business and the supermarkets increasingly controlled the supply and distribution of milk.

^

Go to top of page

International Good Guys ~ Making the world a

better place since 1971 ~ Site maintained by

All material Copyright © Mike

Smith 2003 unless otherwise credited