Departmental Stock and Service Vehicles

In addition to stock for carrying customers goods the railway

companies built large numbers of 'departmental' vehicles for their own use.

These were used by the various maintenance departments for transporting men and

materials about the system. Departmental vehicles would not have wandered on to

'foreign' company lines.

The Permanent Way department, responsible for

track maintenance, requires low sided opens and hopper wagons for ballast and

spoil (used ballast), long flat wagons for carrying rail and sleeper wagons

(often carrying sleepers already fitted with the chairs). Ballast and spoil

wagons out numbered all other types in use of the departmental side.

The GWR had

standardised on steel construction for ballast vehicles but the other

pre-grouping companies favoured wooden bodies vehicles and further examples of

these wooden designs were built by British Railways.

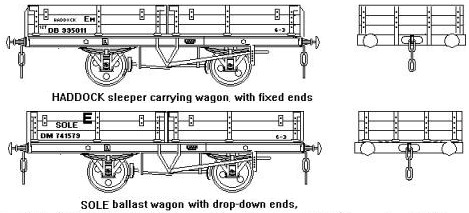

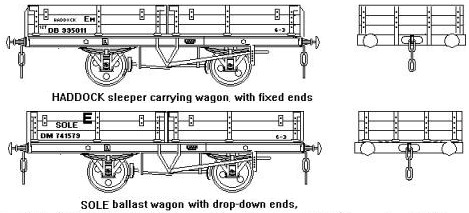

The LMS used very

similar wagons for both sleepers and ballast, these had a longer than normal

body on an extended chassis but with a ten foot wheel base (allowing standard

brake parts to be used for repairs). Both wagons had drop-down sides split into

two sections on each side with a removable post in the middle, the difference

between the sleeper version and the ballast wagon was in the ends. The sleeper

wagon had fixed ends with L shaped stanchions, the ballast version had

drop-down ends which required additional hinged steel posts at each corner.

Quite a few of these wagons were inherited by British Railways and they even

built a few more themselves, British Railways called the sleeper wagon Haddock

and the ballast wagon Sole. These wagons lasted in service into the early

1970's at least. The large letter E shown on the sketch is apparently an LMS

marking still in use in 1969.

Fig ___ Ex LMS Sleeper and Ballast wagons

You can make a reasonable representation of these wagons

from a Peco five plank wagon kit and a fifteen foot wheelbase chassis. Remove

the sides of the wagon body and cut the ends down to three planks high. Now cut

the remaining body into two halves about the centre. Take the ten foot

wheelbase chassis and cut the buffer beams off, then cut the ends of a fifteen

foot wheel base Peco chassis just outboard of the wheels and fit these to the

ends of the wagon chassis, this gives you the unusual chassis. Fit the smaller

weight in place on the new chassis and glue the two body ends in place, this

reinforces the joints and keeps things in line. Add 'three plank' sides from

1mm scribed card and detail using 10x20 thou microstrip (for the ballast wagon

add additional 10x20 thou strips to represent the corner and side bars

described above). The photographs on which the drawings are based date from the

late 60's.

Ballast hopper wagons appeared in the 1890's and

side-tipping wagons for both ballast and spoil were also built. The side

tipping wagons used a screw jacking device operated by the workmen to tip the

body and deposit the load beside the track. Once the ballast was on the track

special ballast ploughs (converted brake vans fitted with large plough blades)

were pulled along to spread it out. Having said which on the Southern lines I

gather it was common practice to drop the ballast on the adjacent track then

use men with shovels to move it into place.

In N Gauge

the Parkside Dundas kit range includes a BR standard ballast wagon, the

Grampus, which bears a strong family resemblance to the designs used by the

GWR. They also offer a SR sleeper wagon, introduced in 1928 and still in

service in the late 1980's and the LNER/BR pipe wagon (a design dating from the

1930's and retained into the 1990's for departmental use). The N Gauge Society

offers its members an etched brass kit of a bogie ballast hopper, introduced in

the 1930's, which serves for BR and SR use.

The Fleetline (former Skytex) range

includes two bogie low sided ballast or spoil wagons suitable for NER/LNER and BR eras. All these

kits are discussed under Available Models - Kits. Dapol have released a ready-to-run model of a 'dogfish' four wheel ballast hopper, a rather neat model produced in a number of liveries.

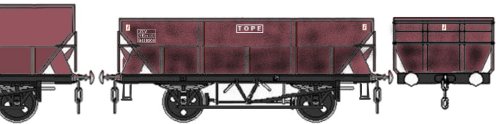

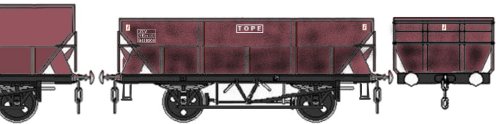

Fig ___ Dapol 'Dogfish' ballast hopper

The re-bodied and vacuum braked version of the BR standard 21 ton hopper wagon (available as a kit from the N Gauge Society and as a ready-to-run model from Dapol) was cut down in height and used for ballast traffic from 1988, coded TOPE with the TOPS codes of ZDV and ZCV. These wagons had the simplified side bracing of the re-built hoppers but could be produced from the Society kit by making new sides from card. The sketch below shows a TOPE with, on the left, a standard re-bodied 21 ton hopper for size comparison.

Fig ___ TOPE ballast hopper

Railway companies had to

renew track as the rails became worn and in normal use the sleepers needed

replacing every twenty years or so. Sleepers are relatively light, so to get a

full load within the loading gauge well-type wagons were often used for this

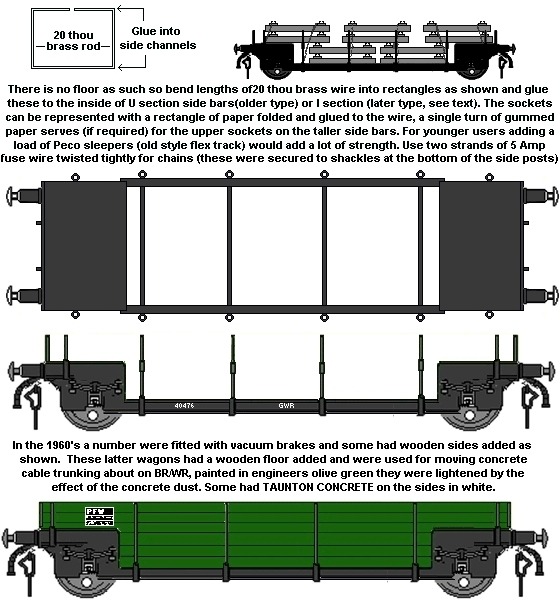

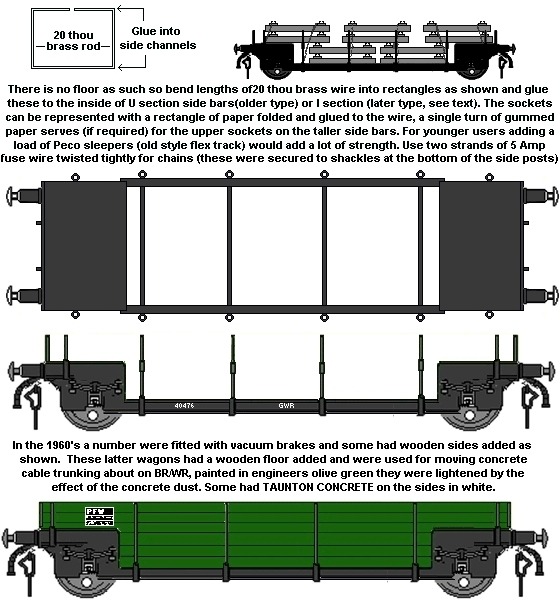

work. I rather like unusual wagons so I built a GWR 'chaired sleeper wagon'

using a Peco chassis and plastic strip. This looked okay but it was not very

strong and is currently in bits having been re-kitted by a youngster. Adding a

load would make this much stronger and in the 1960's some were converted for

use transporting concrete cable trunking on BR/WR. These latter had a wooden

floor and sides added, making for a very robust model. The original T1 GWR

wagons (built at the end of the nineteenth century) have box section side

frames, a later batch built in 1938 (T12) have I section side frames. Some were

piped for vacuum brake and those used for conduit were fitted with a full

vacuum brake. They were just over 34 feet long with a 25 foot wheelbase.

Fig___ GWR T1/T12 Chaired Sleeper Wagon & Concrete Trunking

wagon

If you do not fancy kit

bashing the Peco chassis and have a deep enough pocket there is a model in the

Fleichman range of a four wheeled, drop centred, wagon which can be modified to

represent a GWR or LMS chaired sleeper wagon, the load would take a fair bit of

time to make up however. This has wide side plates which need to be trimmed

straight and thickened to represent the channel section of the British wagon

but would make a very good basis for a concrete conduit wagon.

To

transport the long rails the railways built low sided four wheeled and later

bogie wagons. The early lines used rails in 30 foot lengths so for my own

'light railway' layout I used a Bachman 'old timer' stake car. This scales out

at something over thirty feet in length and has five pairs of steel posts

mounted in brackets on the body side. Posts mounted in this way are unusual on

British wagons, much more common would be wooden bolsters, but the posts on the

bolsters often extended down below the timber and engaged in similar side

mounted brackets. I trimmed away the centre bracket on the Bachman wagon body

and made up two bolsters using wire and Plastruct H section strip (filling in

the strip with Milliput to represent timber). There are various kits now

available for long bogie flat wagons, notably the N Gauge Society 52 foot long

Bogie Bolster D, which can be pressed into service for Big Four era layouts

when rail lengths were typically about 45 feet. For the post nationalisation

scene there are a number of etched brass kits produced by Mr John Grey of

service stock including a GWR/BR bogie rail wagon (coded Gane under the GWR,

Borail under BR). All these kits are discussed under Available Models - Kits.

In the 1940's track was produced as pre-fabricated sections, rather

like Peco Settrack, which were shifted on rail-carrying wagons and manoeuvred

into position using 'Track Relaying Units' (TRU's). These were originally

conversions based on long bogie wagons with a crude crane at each end. The

cranes usually had electric motors and the vehicle had a van attached in which

was mounted a generator. By the 1960's these track laying wagons were slightly

more advanced in design, converted bogie flat and well wagons fitted with

self-powered Coles diesel cranes at each end. Within a few years self-propelled

specially designed and built TRUs were in service, large very complex and

fitted with crew accommodation cabs and rather difficult to model.

Steam railways used a lot of coal, a major loco depot would get through

up to three thousand tons a week, conversely a small branch line shed might

only require one or two tons a week. To move this coal special 'loco coal'

wagons were built. Most of these were basically similar to standard mineral

wagons but some high capacity bogie vehicles were built by the GWR and the MR

at the turn of the century. Not all coal was shipped in company loco-coal

wagons however, I have seen a photo of Exeter shed which as well as GWR Loco

Coal wagons shows wagons from the Midland Railway, Great Central, and London

& North Western Railways, all delivering coal. Some of the 'foreign' wagons

are marked Loco Coal, but not all. There are kits available for wagons built

for loco coal duties and the Graham Farish seven plank wagon is actually a

model of a North Staffordshire Railway loco coal wagon. There were also a large

number of fairly conventional mineral wagons and even redundant goods wagons

(some as small as three planks high) pressed into service for this traffic.

All companies had to maintain 'breakdown trains', comprising

cranes, coaches equipped for personnel along with some vans and open wagons for

tools and equipment. The cranes used were often large steam powered types,

necessary to lift a de-railed locomotive. These breakdown crane trains would be

usually stabled at major depots but might be seen travelling along any line

en-route to an incident.

The majority of departmental stock has always

been for basic track maintenance, in British Railways days this fell under the

aegis of the Chief Civil Engineer, responsible for bridges, tunnels and

buildings as well as the tracks. The Chief Mechanical Engineer, who's

responsibilities included breakdowns and vehicle failures, had his big cranes

and wagons for shifting defective rolling stock whilst the Signal and Telegraph

department had its wagons for moving telegraph poles signalling equipment. Some

of the stock was older wagons and vans withdrawn from service, British Railways

used three plank and five plank former merchandise wagons as 'spoil' wagons and

a few vans were converted for duties such as cable laying.

Fitted and unfitted version were built, the sketch shows the fitted type.

Fig ___

Short pipe wagon in departmental service

The doors on these wagons must have been very heavy to lift

up, I once felt the weight of a three-plank drop-side and that was heavy

enough.

This is a simple conversion from the Peco five plank wagon. Mine was made by carving and sanding the sides flat and scribing the plank lines across, detail was added with plastic strip (10x20 thou for the side strapping with 10 thou rod for the door springs). It may have been less work to remove the sides and replace them with home made scribed card, again adding detail from strip.

Fig___ Model of the BR short pipe wagon

The departmental stock in the post 1967 period has been

increasingly purpose-built, the old 'mess vans' (often converted goods vans

fitted with windows and a set of steps for workers on site) were withdrawn in

the 1970's when British Railways introduced their yellow road vans for

permanent way and signal and telegraph department staff.

Tank wagon

design is considered in a separate section but it is worth noting that the

railway companies operated quite a few tank wagons in departmental service. At

steam engine depots in hard water areas they removed the lime from the water

before using it in the locomotives and the resulting 'sludge' had to be

disposed of. Some of the sludge tanks were of conventional design but redundant

four and six wheeled loco tenders were also widely used. Some of the old

tenders lasted in service into the 1980's, the last would have gone when steam

carriage heating was finally abandoned. The sludge tanks were painted black but

had extensive white staining on the sides where the water had spilled out. If

you see a second hand tender engine for sale as a 'non-runner' (and hence

cheap) it might be worth buying for the tender. You would need to remove any

hint of coal, most of these tenders had the coal space plated over (I am not

sure if this became part of the tank space), so a 'conversion's not difficult

but you also need to add a second coupling to the end formerly connected to the

locomotive.

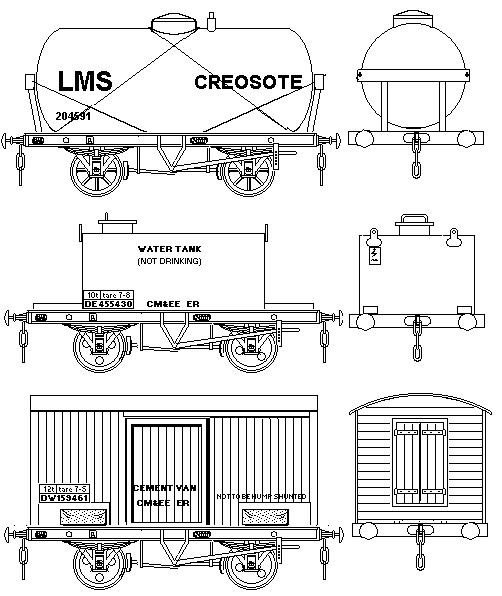

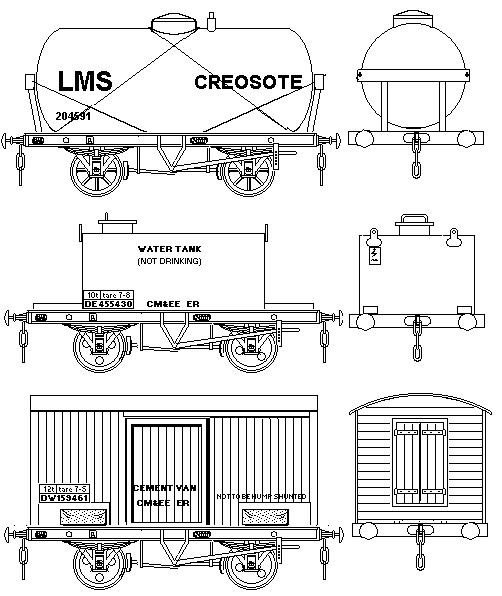

A number of departmental tank wagons were used for

transporting creosote to the sleeper depots and were conventional tank designs

of their day. The railways also had water tank wagons, some were conventional

tank wagons whilst others were redundant loco tenders or simple tanks mounted

on old underframes. In 1946 the GWR allocated six former six-wheeled milk tanks

for carrying drinking water to outlying stations with no mains supply. This

makes an interesting alternative use for a model tanker on a branch with no

creamery but I was not able to confirm the livery used. One unusual example was

a tank wagon built by BR for supplying water to an on-site concrete mixer

(itself housed in a converted van) used in overhead electrification work. This

vehicle had a large square tank on old wagon or van underframe with the body

cut away leaving only the floor.

Fig __ LMS Creosote tank, British

Railways Water tank and cement mixer van

One or two of these departmental water tanks were still

operating in the mid 1980's supplying water for the old steam cranes still in

use. By the 1980's the steam cranes were rare, British Rail preferred

self-propelled diesel units fitted with hydraulic telescopic cranes.

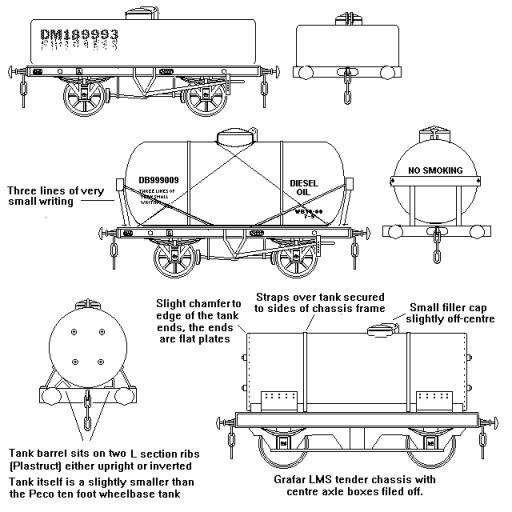

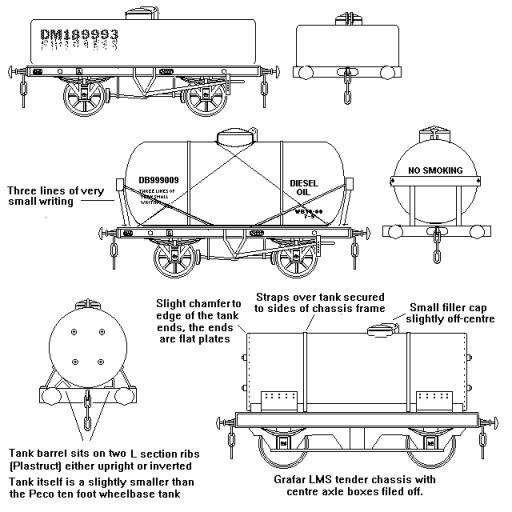

In

the 1990's British Rail still owned a few tanks, some being remarkable vintage

contraptions, most are used for storing oil at loco and DMU stabling points or

MPD's (Motive Power Depots, the term which replaced Engine Shed with the

arrival of the diesels). The two upper tanks in the sketch are drawn from

pictures in Dave Larkin's book on British Railways departmental wagons in the

1960's and 70's. Obvious candidates would be the Peco or Minitrix ten foot

wheelbase tank and the Graham Farish square tank. Both were plain black with

white lettering, note how the fuel oil has smeared the lettering on the square

tank. The bottom tank is based on two I photographed in 1986 at the DMU

stabling point at Northwich in Cheshire. The tank barrels were four riveted

tube sections with flat ends, the edges of the ends were very slightly rounded

and there were four heavy (four inch or 100mm) bolts on each end. The tanks

were mounted on old steam engine tender chassis, the centre wheels and their

associated axle boxes had been removed as shown.

Something similar

could be made up using a Graham Farish tender chassis with a home made tank (as

per the sketch) in which case a 'welded' tank would be easier. The filler domes

on the W&T twin tank kit would be perfect, failing which make a small hole

and fit the cut-off head of a dress making pin. The centre wheels on the tender

chassis could remain in place if you wished. The 'livery' of these converted

tenders when I saw them was a black chassis with everything above plain pale

red oxide (Humbrol 'track colour' mixed with a little white) with no visible

markings. The lids on the filler domes were a dark brown colour.

Also

at Northwich was a lagged tank of the Minitrix type, again painted all over

faded red oxide colour, the diagonal rods to the end supports were painted

white as were the turn buckles on the two wire strops passing either side of

the filler dome. The lid of the filler dome was again a dark brown colour and

the chassis was black.

Fig ___ Fuel tanks for a DMU stable or

MPD

The railways used gas for heating lighting and cooking, the

gas cylinders slung underneath coaches were of limited capacity however so

additional cylinders were mounted on small railway trucks. These could be

loaded and attached to a train or, more commonly, they could be used to top up

the gas tanks on the coaches or at outlying stations and depots. By the later 1940s attaching these to passenger trains was frowned upon, perhaps because the old coach underframes on which many were built were not up to the 'high speed' services then in effect. The gas used

was coal gas, the railways had their own gas works and could also arrange to

buy gas from town gas works on the route (most of which would be rail

connected). Several pre-grouping companies, all the Big Four and British

Railways all operated gas tanks of this type, the earliest photograph I have

seen was taken in 1909 on the Great Northern Railway which resembled the wooden

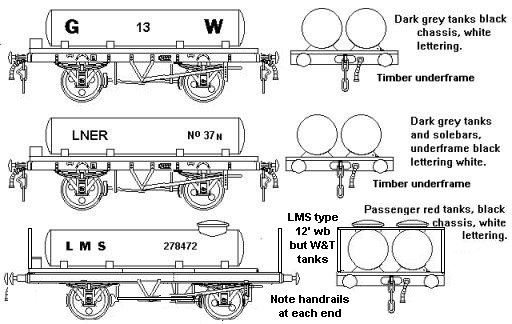

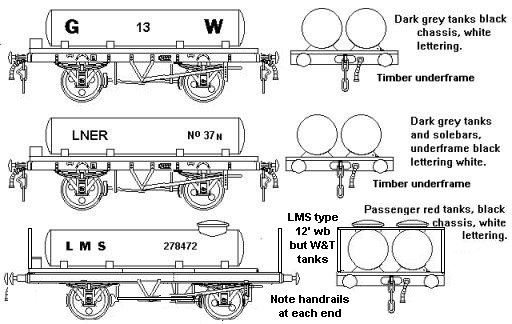

chassis example in LNER livery shown below. The most common design had two or

three cylindrical tanks mounted along the wagon and the drawings below are

based on the W&T white metal twin-tank wagon kit which is close enough to

pass muster in the liveries shown.

The only problem is that the

standard Peco ten foot wheelbase chassis is a bit on the short side when

working with passenger stock, the GWR version described below can pass muster but other

companies favoured a twelve foot wheelbase. The LMS used a W&T sized tank (well a bit longer) on a 12' wheelbase chassis, this can be modelled on a cut-down Peco 15' wheelbase chassis or a Parkside Dundas chassis, adding a plasticard platform at one end with handrails across both ends as shown i the sketch The liveries shown are correct for

the larger tanks and W&T (now sold via Scale Link) can offer additional lengths of tubing, allowing

longer tanks to be produced.

Fig ___

Railway Company Gas Tank wagons

The W&T kit on a Peco wooden

chassis makes a passable GWR gas tank wagon, omit the filler domes and add a T

shaped pipe at the end with the 'boxes' (just visible in the photo), this

connects the two tanks and feeds down through the floor of the wagon. Note the

number on this tank should be 13, it was the only one of its type and the only

short wheelbase tank I was definitely able to identify. The tanks and chassis

were all black (very dark grey looks better in N as colours lighten with

distance).

Fig___ GW

twin gas tank wagon made from the W & T kit

The GWR also used a larger multi-tank wagon which looked like a

stack of rather large oil drums mounted across the wagon in a heavy looking

metal frame. This represents a serious challenge for the scratch builder

however.

In the later 1920's or early 1930's several larger gas tank

wagons were built based on a single large tank. I have not been able to trace

the operational details but a model of such a tank is not difficult to

construct. The LMS built two quite large tanks using fifteen foot wheelbase

chassis, the tanks themselves being mounted conventionally for the time in a

frame with straps to hold them down and end stanchions to hold them in

position. Something quite similar can be built using a Peco fifteen foot

wheelbase chassis and a Peco ten foot wheelbase tank kit body. Cut the

sub-frame from the Peco in half and glued to the chassis. Next cut away the

centre section of the tank and add a length of tube (or paper wrapper) in its

place to extend the tank to the required length.

There were also wagons

delegated for delivering coal and collecting ash from signal boxes. These were

usually standard open wagons of conventional design but they represent an

interesting option for operational traffic. Horses consumed a lot of hay and

produced considerable quantities of manure. The cattle pens at stations

handling a lot of this kind of traffic would also have a lot of manure to be

disposed of. This was not thrown away as it was a useful fertiliser. Several

companies built specialised wagons for collecting manure, as manure is not very

dense these wagons usually had larger than normal bodies. Most of this material

was shipped in plain mineral wagons, where the potential for contamination

would be less of a problem. As recently as the 1950's BR was shifting over two

million tons of manure a year. Some of this was single wagon loads from the

stables used for goods shunting horses and few remaining delivery horses at

stations, some was shifted in a rake of wagons from a major cattle centre (such

as the docks where cattle were imported or from stations with extensive cattle

pens following a market).

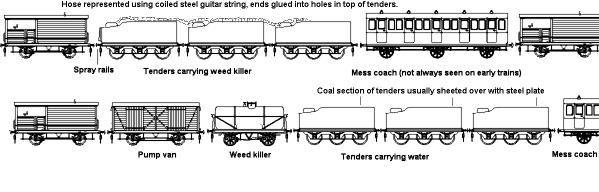

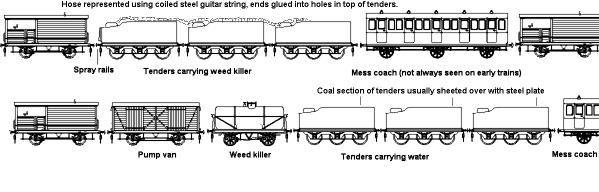

The railways have to contend with weeds

growing in the ballast along the line which interfere with drainage and could

make the track unstable. In the early years the gangers walking the line were

expected to deal with the weeds but by the mid 1930's weed-killer trains were

being operated by the larger companies (liquid weed-killers had been around

since the 1890's at least). Weeds are difficult to kill however and on branch

lines and 'light railways' there were often weeds growing along the track.

Early weed killing trains were operated by the railway company

themselves, initially they consisted of a short rake of redundant locomotive

tenders filled with the weed killing solution. The tenders were connected

together with fairly large pipes (about four or five inches (100 125mm)

diameter) and the locomotive provided steam which was used to force the

solution out of a series of spray rails on the rear of the last tender.

By the 1940's these trains were made up of three or four old loco

tenders to carry the water, a tank wagon to carry the liquid weed killer, a

pump/spray vehicle (often a converted long wheelbase or bogie van), a

stores/mess van (usually a converted coach) and a brake van or two. Having a

van at each end made it easier for the locomotive to run-round the train for

the return journey. By the 1950's there were usually four or six tank wagons or

redundant six wheeled locomotive tenders (or a mixture of both) carrying a

ready mixed solution of weed killer, pump van, mess van and brake van(s).

British Railways employed private contractors for this work from about

the 1960's, originally Fissons the fertiliser people handled the job, and up to

the 1970's the equipment remained as before. Since then the contract has passed

to Hunslet Barclay of Kilmarnock who employed a train consisting of two

modified bogie parcels vans with three four wheeled forty five ton tank wagons

(of the type offered by Peco). The rake was normally handled by Class 20

locomotives, often operated as a pair and owned by Hunslet Barclay themselves.

The locomotives were subsequently sold to Direct Rail Services for use on their

freight trains. I do not know who now handles the weed killing duties.

Fig___ Weed Killer Trains

On

the departmental side the Fleetline range includes a Cowan Sheldon hand powered

rail crane dating from the 1950's and a pre-war 45 ton steam crane. Parkside

Dundas offer the 'grampus' ballast and spoil wagon and of course the

departmental stock inherited from the Big Four and available from Fleetline

continued in use for many years.

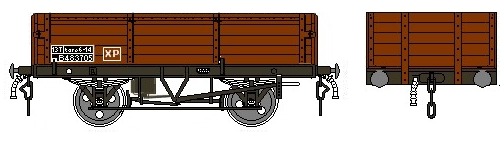

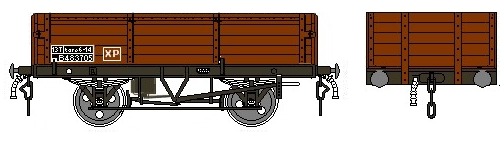

Following the Beeching changes and

Barbara Castle's Transport Act there were large numbers of redundant open

wagons transferred to the engineers, notably the drop-side three plank wagons

as available from Fleetline.

One odd option seldom modelled is the 'match wagon' used to allow a vehicle with non-standard couplings to be attached to a train or hauled by a locomotive. One example is the old Palbrick wagons which were modified to couple up to individual Freightliner 'inner' wagons and other types of non-standard stock. These were painted plain blue with the TOPS codes RGQ and RFQ and had the sides removed, although otherwise they were unmodified as far as I could see. The last time I recall seeing one of these in use was in the later 1980s, although they may well have lasted a lot longer as they would recieve little wear and tear.

Fig___ Palbrick based match wagon

Generally these are confined to yards where such stock may be taken out of service, but some match vehicles are used to transport non-standard stock on the system.

The example below is the match wagon used to pull the Eurostar set about (last used in the later 1990s I believe, whern there was the promise of a Eurostar service direct from the North West of England). I believe the photo was taken in the later 1990s, but cannot confirm the exact year. The unit was being held in a bay platform at Stockport station, the base ofr the service was at the former Freightliner yard in Longsight (South of Manchester), now used as a service point for more mundane multiple units.

Fig___ Eurostar match wagon

The close up below shows the hinged coupling bar on the Eurostar end of the wagon.

Fig___ Eurostar match wagon couping

^

Go to top of page

International Good Guys ~ Making the world a

better place since 1971 ~ Site maintained by

All material Copyright © Mike

Smith 2003 unless otherwise credited