International Good Guys ~ Making the world a better place since 1971 ~ Site maintained by

All material Copyright © Mike Smith 2003 unless otherwise credited

| Return to Loads and Handling Index |

|

Length of wagon | 2 plank | 3 plank | 4 plank | 5 plank | 6 plank | 7 plank |

|

15 feet | 120 cu ft | 180 cu ft | 240 cu ft | 300 cu ft | 360 cu ft | 420 cu ft |

|

16 feet 6 inches | 132 cu ft | 198 cu ft | 264 cu ft | 330 cu ft | 394 cu ft | 462 cu ft |

|

17 feet 6 inches | 140 cu ft | 210 cu ft | 280 cu ft | 350 cu ft | 420 cu ft | 490cu ft |

|

21 feet 6 inches | 172 cu ft | 258 cu ft | 344 cu ft | 418 cu ft | 516 cu ft | 602 cu ft |

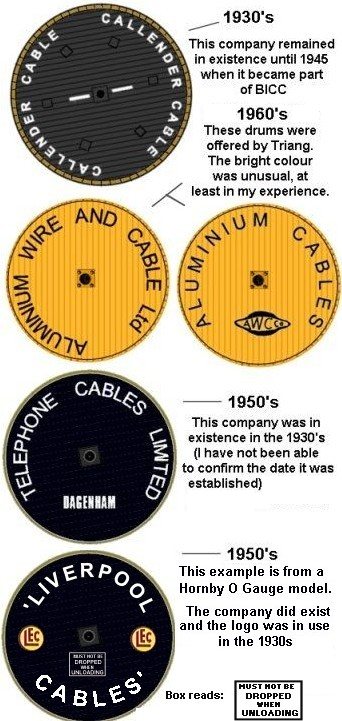

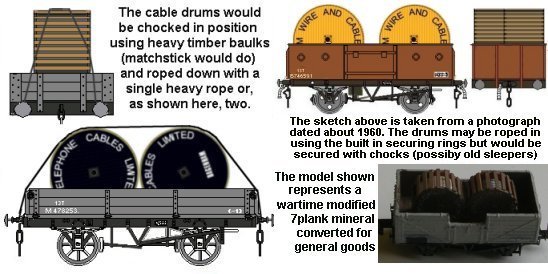

I have a copy of the BR 'Instructions for handling and loading specified Traffics' dated May 1957 that covers cable drums. There is no specific guidance on how to secure in a wagon (sections on some other goods do provide this) however the section on cranage states that the maximum size of steel spindle which can be accommodated in the spindle hole must be used. This will ensure the spindle is not over-stressed. It also states that the use of a beam or spreader is preferable to avoid undue pressure on the flange (the outer edge of the drum).