Horse drawn vehicles, mainly private carriages and traders vehicles, farm equipment and motor vehicles (both cars and lorries) have all been regular cargo for the railways. Most horse drawn vehicles were shipped as a one-off load, classed as wagon load traffic and attached to conventional mixed goods trains. Where an entire train load of horse drawn vehicles has been photographed these are normally military standard 'General Service' waggons being moved for the army. Modelling these waggons is discussed under Cargo & Wagon Loads. One exception was a service operated by the LSWR for horse drawn meat vans. The vans had their wheels removed in London and were then craned onto purpose built flat wagons (coded RUCK and later used for containers, see Unit Loads (containers, pallets and IBCs) section). They ran as a block train down to the docks at Southampton where the vans were loaded with chilled imported meat. The train was then taken back to London as an express goods service where the vans were craned off the wagons and their wheels re-attached for deliveries to butchers and the like.

Road tank wagons were sometimes used for beer from the later 1930's and post war they were also used for various chemicals. The types associated with this traffic are discussed below, the type used for milk traffic is considered separately under Non Passenger Coaching Stock Operations - Milk.

Horse Drawn vehicles, Cars & Lorries

By the 1930's most road vehicles shipped by rail were new cars and vans being moved around the country. These were mainly moved on existing four wheeled 'open carriage trucks' or more modern vehicles built to broadly similar designs. At the time mass production was not quite so massive so a consignment might consist of perhaps five or six vehicles going to a dealer, or even a one-off if the vehicle was from the upper end of the market. These would be forwarded is a cut of wagons in conventional mixed goods trains.

Cars being transported by sea were often enclosed in a large wooden case with the framing on the outside. This was craned onto the railway wagon and quite often the car was then driven into it. At the docks it would be lifted onto the deck of the ship and strapped down. Bulk cars for export were often shipped as CKD or 'cars knocked down'. The chassis were nested in batches of four or five, the body sections were similarly nested, the wheels were bolted together in groups of four and tyres were stuffed in wherever they would fit. The engines were shipped in wooden cases. This collection of parts was shipped in open wagons or vans, depending on what was available and how easy they were to load. A consignment of perhaps twenty cars would only require flour large 'plate' wagons for the chassis, four or five open wagons for the body parts and engines and perhaps a van or two for the remainder.

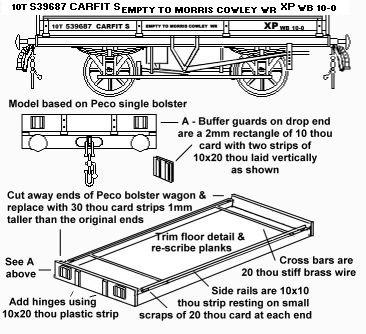

By the 1930's there was some traffic in new cars to and from continent via the rail ferry services. The railways modified some car carrying flat wagons with securing points so they could be used on these ferries. I have not found any illustrations of cars being imported in this way but J H Russels book Wagons & Loads on the GWR and BR/WR (see Bibliography) includes several photographs of British rail flats. The Carfit S was equipped by the Southern Railway with dual air and vacuum brakes specifically for ferry operations to the continent and it happens to be one of the easier models to make, brief details are shown in the sketch. The two cross-bars each had two white canvass straps attached to them, these were secured round the axles of the car. If required they can be represented by 1mm wide strips of cigarette paper folded over the cross-bars and glued to the floor. The cross-bars were attached to the side rails and could be moved along the wagon, do remember to fit yours so that the intended load can fit between them.

Fig___ Carfit S used for ferry traffic in the 1950's and 60's

By the 1950's the traffic in new motor cars was increasing and block trains were increasingly being run. There is a photograph in Dave Larkin's book BR Standard Wagons (Bradford & Barton, see bibliography) showing one of the early 'Bocar P' conversions for moving new cars about the place. These had neither sides or ends but had metal channels built into the floor to locate the wheels. From the photographs these were recessed into the floor as noting appears to show above the planking. There was one fixed and one folding flap to allow movement between wagons. This vehicle is fairly easy to model although lacking a proper photograph of the deck there is some guesswork involved. Take a Farish 57 foot chassis and add a deck of 10 thou plain card overhanging the sides by about 1mm. N now add three strips of 1mm planked card, one in the centre the others laid up to the edge of the 10 thou floor, these three strips need to be cut to allow gaps for the metal channels. Sand the sides down to about 0.6mm overhang at the sides by wrapping the fine sandpaper round a block of wood, lay the chassis upside down on a strip of gash card and rub the chassis against the paper. This should give you a dead flat side. Finally add a strip of 10x10 thou along the outer edges and sand again to blend in this last joint, you now have 1mm height to add lettering.

The later wagons used for this kind of work had low sides of rails and stanchions with ends which were 2 planks deep (See 'Illustrated History of BR wagons' pages 82-5, where there are both photos and drawings). These later Carflats were also used for Motorail services, described in the section on Non Passenger Coaching Stock Operations.

BR's stock of open Bocar and carflat car carrying wagons (converted ex passenger coach chassis) were less than ideal for new car traffic, mainly due to the amount of siding space they required for a given number of cars carried. Following some not terribly successful experimental designs in the 1950's double decked car carrying wagons were further developed in the 1960's. The BR Cartic Four (1964) and privately owned French designed Autic Six (1981) wagons were introduced for motor cars whilst the carflats and some converted Freightliner bogie flat wagons were used for vans and larger commercial vehicles. These are virtually all loaded and unloaded at privately owned depots. Most commonly the lower deck of the car carriers is accessed with a pair of perforated steel channels laid up against the end of the rake. The upper deck is then accessed via a bogie flat wagon with a ramp mounted on it, the steel channels are used to get the vehicles onto the wagon, the car is driven along the wagon then up the ramp at the far end. The angle of the ramp is about 35 degrees from the horizontal, which is steep.

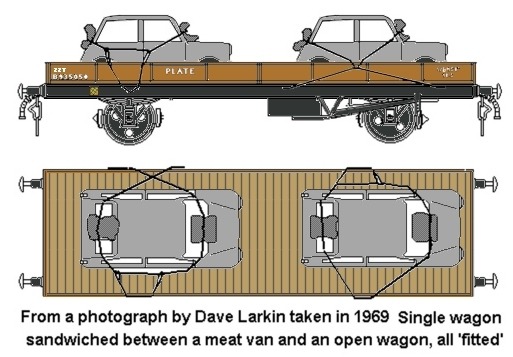

Small shipments, cars going to a dealership for example, were most often moved by road transporter (avoiding wear and tear and possible damage in transit). There is a well known photo of two 'Mini' cars roped down to a plate wagons in Dave Larkin's Bradford and Barton paperback book on BR Standard Wagons (see bibliography), however I believe this shipment took place when there was a strike by road car transporter drivers and very few cars were moved in this way. The photograph is interesting in that it shows how awkward it was to ship modern types of car, which did not have the axle to which straps could be attached. Whereas machinery tends to have plenty of places to attach chains for securing the load motor cars are rather flimsy and need to be secured with care. The sketch below was made as a working drawing based on the photo when modelling this load, as the book mentioned above is long out of print I doubt Mr Larkin will object to its inclusion here. Note the bags of straw used to prevent the ropes from scratching the cars.

Fig___ Cars on a plate wagon

In the early 1980's, with Speedlink in operation and the smaller non-articulated Procar 80 in service, motor cars and commercial vehicles became regular components of the mixed traffic rakes. This traffic ended with the ending of Speedlink services in 1991 but in 1999 Freightliners were looking at a double-decked six car carrying container which could be used for positioning hire cars or making smaller deliveries to dealers.

Lorries were a less common railway cargo than cars, the rolling chassis was usually built by one firm and the bodywork added by another. It was common practice to drive the chassis from one factory to the other on the roads. I believe this practice continued into the 1960's, after which the danger to the driver riding an exposed chassis became an issue. Where commercial lorries were transported their height meant they often required 'lowmac' drop centre wagons. Most of the weight was at the end with the cab and engine so this would be parked in the well (gaining clearance from the drop centre) but the rear wheels might well be up on the ramped end.

In about 1984 a new air braked vehicle was introduced specifically for lorry traffic, called the Comtic it was an articulated six wheeled vehicle resembling two lomacs fitted together and sharing a centre pair of wheels. I believe the design is a single decked variant of the successful Autic Six twin deck car carrier. The Lima articulated car transporter makes a good basis for these wagons, simply cutting away the supports for the upper deck produces something very similar in appearance to the Comtic. The Lima model can be used to make up an Autic Six but if accuracy is important to you that involves making new supports for the upper deck from plastic card cut to the correct shape, slightly different to the Lima design.