Air braked wagon development

Please note the air braked era is not an area of particular interest

to me. I have made notes in case I started to model this period but there may

well be errors in the text and or the illustrations that follow.

On

what is primarily seen as a passenger railway system the demand for ever higher

speeds and development of improved suspension and braking systems has

continued. Whereas the pre-war goods trains had typical speeds for unfitted

stock of only 25 miles per hour, current practice calls for air-braked stock

operating at speeds of 60 mph or more when fully laden. These higher speeds do

not confer any real commercial advantage, it is generally agreed that railway

freight moved at speeds of 40-50 mph is probably the best compromise between

efficiency and economy. The additional cost of building the high speed rolling

stock has probably cost the railways some business, they do however make life

much easier for the people routing trains. In the USA, where the economics of

the late 20th century have just about killed all but commuter passenger

traffic, most lines are basically freight only. Average speeds of 30 mph or

less are not uncommon, with many lines restricted to a maximum of 50 mph even

for passenger stock.

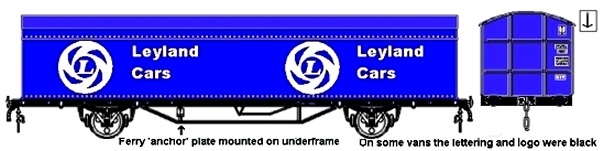

Vehicles fitted with both air and vacuum brakes

were built for ferry traffic in the pre-war era and more were built by BR. In

the 1960's BR conducted a series of experiments compare air and vacuum brake

systems, making much use of the ferry stock to do this.

As well as the

ferry vehicles they built a series of prototype wagons, starting in about 1962

with a small number of 'tube' wagons. I believe these were essentially the same

as the later OAA (as available from Grafar) but I have not found any

photographs to confirm what they looked like.

Several experimental open

wagon and van designs were then built using a common air-braked chassis (one of

the curtain sided experimental vans from a batch built in 1966 is included in

the sketch below). These were judged a success and British Railways set about

building a fleet of open and closed vehicles on this standard chassis . This

was before TOPS and the new vans and open wagons were coded COV-AB and

OPEN-AB.

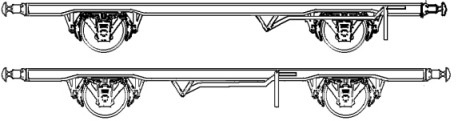

The initial British Railways standard four wheel air-braked

wagon chassis appeared in 1969 and was 33 ft. 6 ins (10211 mm) over all length

with a wheel base of 24 ft. 9 ins (6324 mm). This chassis was developed from a

small number of prototypes. The 'standard' was somewhat flexible however and

there were variations in the suspension and the positioning of the brake

handles. One point to note is that the brake gear under the wagon was offset to

one end, so the brake handles were different on each side of the

chassis.

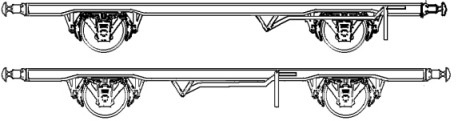

Fig___ BR standard AB chassis

The early form

of air braked chassis is used by Graham Farish and Taylor Plastic Models for

their modern image models and the latter firm also offer the basic chassis as a

separate item.

It was decided that the air brakes, which require less

bulky equipment on the wagon, were preferable for modern stock. Series

production of air braked vehicles for purely British use began in 1964. First

to appear was the HOP 32 AB merry go round hopper wagon (now coded HAA)

followed by the small-wheeled bogie Freightliner flat wagons (now coded FFA and

FGA) and the Cartic Four car carriers (TOPS coded PQA for PO types, FQA for

British Rail owned stock). The Cartics and other similar vehicles are discussed

later in this section.

The HOP 32 AB mineral hoppers (TOPS coded

HAA/HDA/HFA) used for supplying power stations with coal became the most common

single type of wagon in the modern fleet. They have a chassis which is 27 foot

2½ ins (8001mm) over the headstocks with a wheel base of 18 foot 11 ins

(5561mm). A model of this vehicle was available from Minitrix.

Quite

early on, before TOPS was introduced, fifty seven of the HAA hoppers were

fitted with a solid roof equipped with what appears to be a single hatch

running the length of the top (I have yet to find a photograph showing the tops

of these wagons). Originally coded COVHOP 32 AB, changing to CBA under TOPS,

they have been used for lime traffic as recently as 1995. I had thought from

photographs that they were painted 'freight brown' rather than the plain metal

of the standard HAAs but I understand that they were in fact just very dirty.

There was presumably a CAA covered hopper but to date I have traced no

information on these and they may not actually have been built. The last major

order for wagons by BR before privatisation was for a conversion to more of the

HAA hoppers for china clay traffic. Built in 1988 and TOPS coded CDA these have

a power operated canvass roof, rising to a central longitudinal roller device.

I believe the body of the wagon is painted white but I am not sure about that.

(There is a conversion kit available for the Minitrix HAA to convert it into a

CDA)

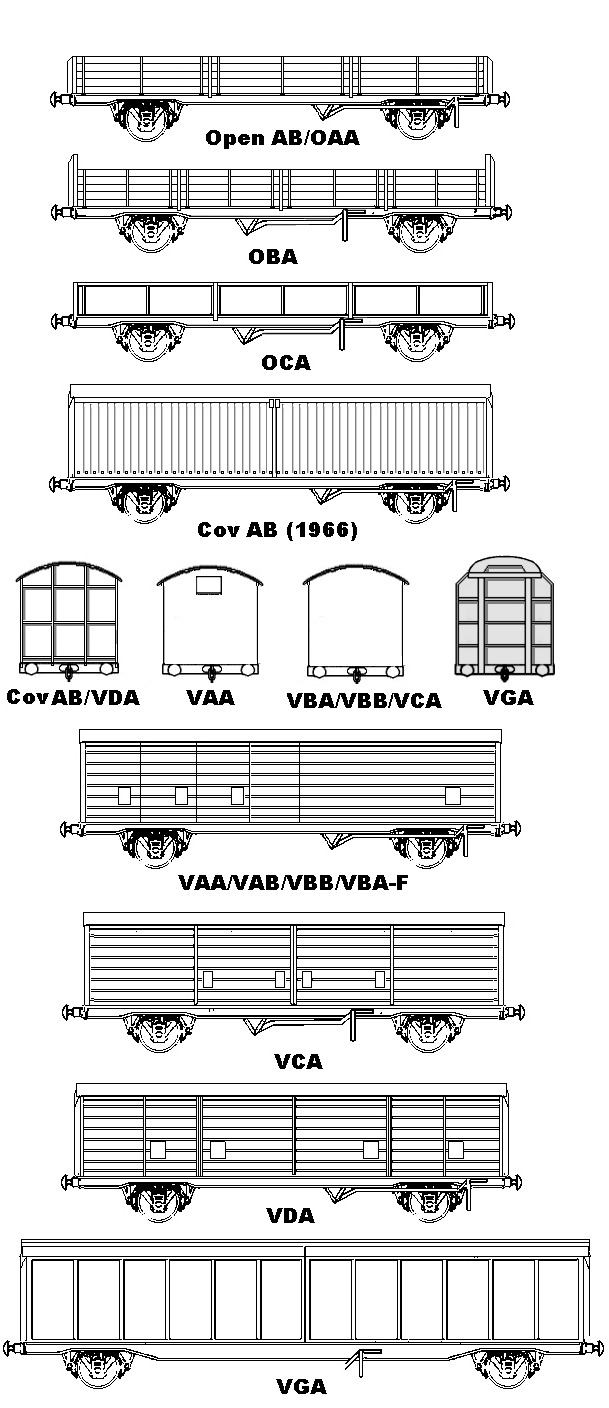

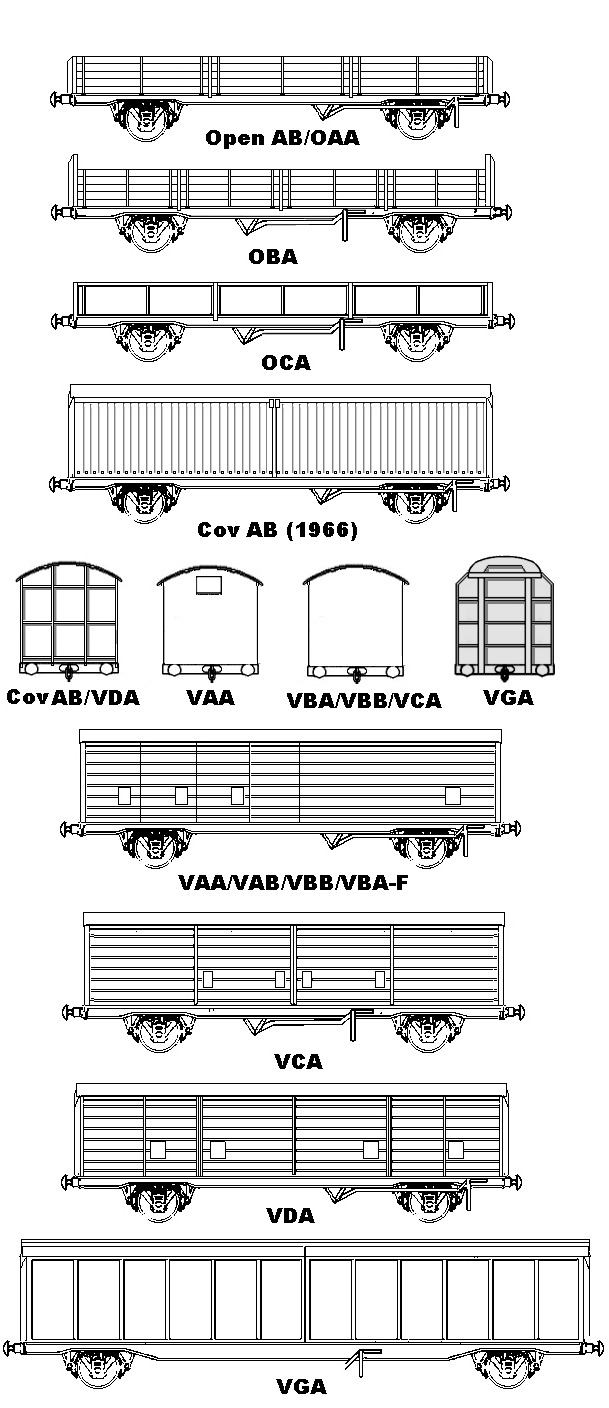

Following the prototypes of 1966 the first open wagons for the new fleet were the 31 ton payload/45

ton GLW OPEN-AB (TOPS coded OAA) open wagons. These were introduced in 1971 and

a model is available from Graham Farish. Wooden bodied the sides were made up

of three drop down doors with removable stanchions so the whole side could be

opened for loading. These wagons were supplied with their own green tarpaulins,

marked 'TO BE RETAINED WITH AB WAGONS ONLY'. Cargo for these wagons has

included various palletised loads such as bricks and roof tiles, large crates,

steel bars and (with a tarpaulin added) bags of grain and rolls of newsprint.

Several of these wagons were transferred to departmental use and were re-coded

ZDA 'Squid'.

An alternative wooden bodied open design was the OBA

(available as an etched kit in the John Grey range). The prototype was built in

1974 on a redundant steel carrying SCA chassis (which had itself been converted

from an OAA). Series production of the type began in 1977 an this proved to be

a successful design. The OBA has sides made up of four drop doors, again with

removable stanchions to allow the whole side to be opened for loading. The

floor has bolsters which can be folded down out of the way when not required,

allowing loads of steel to be carried. The ends are two planks higher than the

sides to support a tarpaulin and loads would be as for the OAA above. By the

mid 1990's most OBA's had transferred to the departmental fleet, re-coded ZDA

'Bass' but quite a few were sold and formed the basis of a number of Private

Owner vehicles.

The OCA, introduced in 1981 is a steel bodied open

wagon, still with drop down sides in three sections and with removable

stanchions. The floor is fitted with a series of bolsters which are not

removable, these were added to allow the wagon to be loaded with hot steel

sections. The OCA wagons were originally built on redundant steel wagon chassis

and loads would again be as for the OAA but they were built for carrying steel

and were often used for coils of steel wire.

Air braked vans were built

in greater numbers than the open wagons, following the preference for van

traffic evidenced in the vacuum braked services. Unlike the open wagons all

early batches of vans were piped to work with vacuum braked stock. Following the prototypes of 1966 the first air braked van design to

appear in 1969 was the COV-AB (TOPS coded VAB, the un-piped examples were VAA)

with half length sliding doors and with a single hooded vent at each end.

Variants on this were the non-vented VBA as offered by Graham Farish (it is

marked VAA but so were some BR vans) and VBB, a sub variant was the VBA-F which

may have been insulated. The bodies of all these vans were essentially similar,

the sides were identical. All had a 30 ton maximum load when running at 60 mph

but the maximum load at 70 mph was only 20 tons for the VAB and VBA, improved

suspension on the VBB allowed high speed running with about 24 tons. One common

use for these vans was the Rowntrees confectionery traffic from York.

VCA and VCB are variants on another standard design with centre sliding

doors and no end vent, some VCB's have lashing bars and these were sometimes

used for banana traffic. The maximum load at 60 mph is 30 tons, at 70 mph this

falls to about 25 tons. The VCA's proved less than successful and in the later

1980's many were transferred to other duties, quite a few ended up as barrier

vehicles whilst others were converted to FPA wagons for carrying thirty foot

long coal containers and some were sold to the Ministry of Defence. The VCA

chassis has been used for a number of Private Owner conversions, including (in

the later 1990's) a fleet of open wagons with high square ends and drop-down

mesh sides for Plasmor. These carry palletised lightweight concrete building

blocks from the factory to the depots.

The VDA/VDB appeared in 1976,

these have an external frame on the ends (as seen on some early prototype vans,

see sketch below), no end ventilator and hinged centre doors with separate

quarter doors at the outer ends. These could carry 31 tons at speeds of up to

60 mph but this was reduced to twenty one tons for speeds up to 70 mph. This

proved to be one of the more successful designs and they have remained in

demand throughout the 1990's. I believe they were the most common type of air

braked van built by BR.

In 1981 the prototype for a new van was

introduced on a new and longer chassis, this was the VGA, a 42 foot long,

sliding-wall van with a wheelbase of 29 feet 6 inches. Based on a German built

design originally produced for Ford (UK) these have proved to be a very

successful vehicles. The body had heavily ribbed ends and the roof forms only a

narrow strip along the centre line. Each side consisted of two sliding doors

made of light alloy and the upper part was bent inwards, forming part of the

roof. This arrangement allowed loads to be craned into the van and provides

easier access for fork lift trucks. To increase the carrying capacity the

section between the wheels was dropped to form a well and the actual capacity

of the vans was some 75 cubic metres with a 25 ton payload. Some VGA vans were

later fitted with modified bearings and coded VKA.

The last British

Railways van design was the VHA although I only know of one of these, a

prototype converted from a VDA. The VHA was an interesting 25 ton design with a

solid roof, low wooden drop sides and a plastic 'curtain' covering the upper

two thirds of the sides. Unlike the earlier curtain sided vans however the

curtain was supported on a light tubular metal frame and hinged upwards, which

saves a lot of time during loading and unloading. The prototype was later

converted to an OTA timber wagon (discussed below).

By the mid 1990's

of all these early van types only the VDA and VGA vans remained in regular

service although odd examples of all types were seen. The hinged and sliding

doors on the older vans have given problems and replacement curtain sides may

be fitted to many of those which are to remain in service.

Fig ___

British Railways standard air-braked rolling stock

In about 1980 several of the old ten foot wheelbase 'vanwide'

vans were converted to air brakes and re-coded VEA (for those with roller

bearings) and VFA (for those with roller bearings and an alarm). They were

intended for use carrying military supplies, the short wheelbase being better

suited to the tight curves in military establishments, but by the mid 1990's

these were all in departmental service and coded ZSA or ZRA.

In 1983

fifty of the old twelve foot wheelbase pipe wagons built by British Railways to

an LNER design were converted to air brakes and coded ODA also intended for

Ministry of Defence traffic.

The non-MGR air braked mineral hoppers

(HBA/HEA/HSA), originally intended for domestic coal traffic, appeared in 1975.

These wagons have a chassis which is about twenty five foot over headstocks

with a fifteen foot wheelbase. Taylor Plastic Models offer a body kit of this

wagon to suit the Peco fifteen foot wheelbase chassis. Some of these were later

fitted with a canvass roof with central roller, essentially similar to those on

the CDA china clay hoppers. These modified vehicles were coded CEA but I do not

know what traffic they were used for. I understand that the kit for modifying

the Minitrix HAA hopper can be used on the Taylor HBA body to produce a

CEA.

The steel industry has been one of the railways better customers

and British Railways has always operated large numbers of steel carrying

wagons. The unfitted bogie steel carriers built in the early British Railways

period were all scrapped or transferred to the engineers departments by the

early 1980's but some of the vacuum braked early British Railways designs

lasted into the early 1990's operating as block trains. By the mid 1990's only

new air braked designs and upgraded stock retro-fitted with new air braked

bogies were in service.

Quite a number of specialised steel carrying

wagons were built on the standard four wheeled air-braked chassis. The SAA was

the first to appear, three hundred of the type being built in 1971, the SAA had

drop-down posts along the sides and drop down ends. Taylor Plastic Models

offers a kit of such a vehicle to fit the TPM/Graham Farish chassis. Oddly

enough these were seldom used for steel and spent most of their working lives

as runner wagons. By the mid 1980's they were being re-coded as runners with

TOPS codes RRA RAB RBA and RRB.

The SCA (Coil C) 24.5 ton wagons

appeared in 1977, open wagons with four section steel drop sides and with a set

of hinged vertical side rails. These were built for wire and rod coil traffic

(mainly from South Wales) and were re-coded SAA in 1988 when the original SAAs

had all been transferred to runner duties.

Also in 1977 the first SPA

steel carrying wagons appeared, the modern version of the old plate wagons they

have a steel body with three section drop sides. Over a thousand of the type

were built and they were initially used for pig iron.

The SDA was a 2

axle bolster wagon, the SEA code was originally intended for a conversion of a

bogie wagon to a four wheeler but this was never completed and the code was

then used for a plate wagon with three section drop sides introduced in 1979.

The SFA is a variant of the SEA fitted with a nylon canvass 'tilt' so they can

carry unfinished steel sections.

By the mid 1980's there were twelve

types of four wheeled steel wagons listed in the TOPS 'S' series with another

eight two-axle coil types listed in the 'K' series (these were then re-coded in

the B and F series).

There has been a continuing program of up-grading

the steel carrying stock, funded by the steady profit from the traffic. As an

example the forty five foot long vacuum braked Bogie Bolster C were built to

carry thirty tons but were subsequently up-graded to 42 tons capacity and

fitted with air brakes (TOPS coded BCA). Similarly the forty two ton payload

fifty two foot long Bogie Bolster D of 1960's vintage was fitted with a

strengthened underframe and new air braked bogies in the late 1970's to handle

58 ton loads with a tare of 22.5 tons, these are TOPS coded BDA.

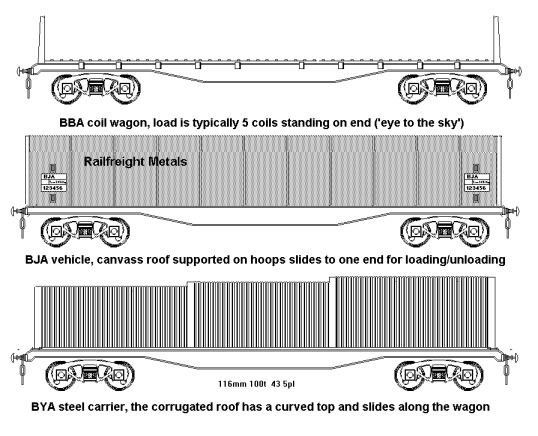

The

first new air braked bogie steel wagons to appear were three hundred or so 40

foot long Bogie Steel AB wagons, TOPS coded BAA, first built in 1972 and rated

at 76 tons payload. These were followed in 1973 by the BUA with a capacity of

42.5 tons and in 1975 by five hundred or so BBA. The BBA is a 52 foot wagon

rated at 74 tons payload, similar in appearance to the BAA but longer and with

deeper channel sections along the sides. In 1977 two hundred BMA (Bogie Coil M)

fifty foot long wide-body bolster type wagons rated at 58 tons were built. In

1979 the BOA bogie coil wagons were re-built for steel strip coil traffic,

these carry 53 tons apiece.

In the mid 1980's there were nineteen wagon

types listed in the B series (bogie steel wagons) and another twelve in the J

series (bogie coil wagons). The J series were then integrated in the B series

and there appear to have been some cases where old codes were re-used.

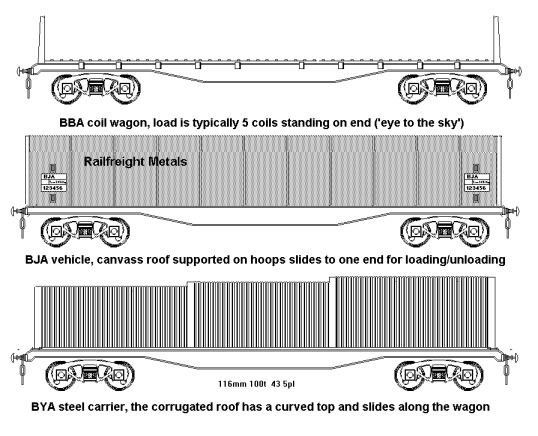

The French designed Debauch Vite wagon appeared in privately owned

British wagon fleets in the early 1980's, this has fixed ends similar to a

standard van but the body is a tarpaulin supported on a series of inverted U

shaped hoops. The hoops can be moved along the wagon (this is power assisted)

so the tarpaulin can be quickly drawn back allowing loads to be craned into the

wagon. These wagons proved popular for steel traffic as they offered protection

from the weather. In 1990 British Railways built four prototypes of three

essentially similar wagons, coded BGA (13m long 64 tons capacity), BHA (16m

long 61.5 tons capacity) and BJA (19m long 63 tons capacity). There are no

commercially available models of this general type but the design is

essentially simple to model. One option for this is discussed in the section on

Kit Bashing.

The very latest design is the EWS 100 ton bogie steel coil

wagon coded BYA. This is an unusual vehicles with a three section ribbed

telescopic roof. The design is reminiscent of the VTG owned German built

telescopic hood wagons (described in the section on PO wagon design) but the

hood is lower than on the German design and the tops of the hood sections are a

simple curved shape.

Fig ___ Modern steel carrying vehicles

The above form the backbone of the railway owned air

braked stock but there are many variants and modifications. Some of the

variants are available as models or kits, regarding which see the section on

available models. There were of course many conversions used for steel traffic,

amongst the air braked stock there were several four wheeled plate wagon

conversions such as the 31 ton SDA bolster, the 22.5 ton SEA rod-coil wagons,

the SHA (Coil T) 31.5 tons strip coil wagons and the SRA 24.5 ton rod-coil

wagons.

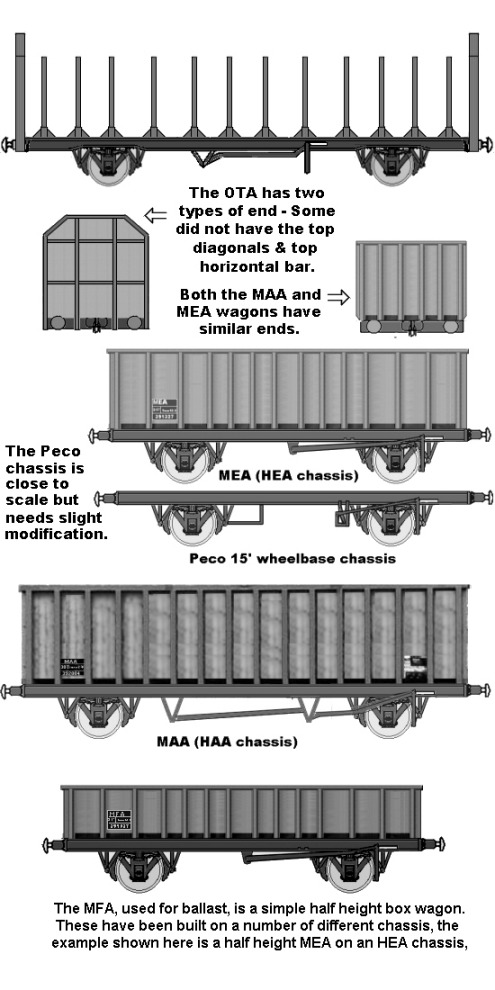

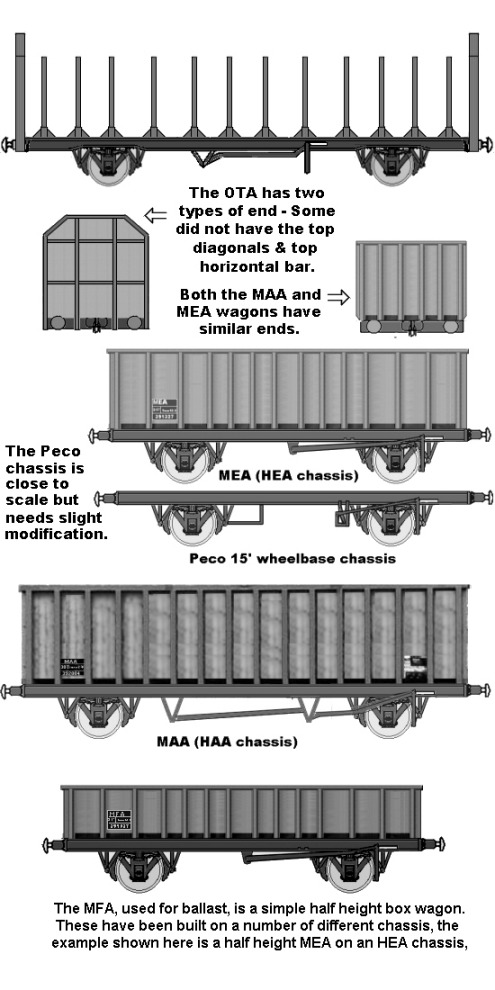

Timber traffic in Scotland has continued to be worthy of

railway investment and the OTA timber carrying wagons are similar to the old

Timber P vacuum braked vehicles but based on the longer air braked chassis. The

first lot were built using chassis from redundant OCA wagons in 1985, a later

batch was built using redundant VCA chassis. The OTA has solid ends but no

roof. Ranged along the sides are either twelve or thirteen sockets to hold

vertical posts and the load is strapped down using two straps attached to

fittings mounted between the side posts.

The MAA is a mineral tippler

built on redundant HAA merry-go-round hopper chassis and introduced in 1990.

These wagons have a simple box body with external framing which could be made

up quite easily using plastic card and microstrip. The chassis could be made up

using a Peco fifteen foot wheelbase chassis with a 4mm section cut from another

chassis inserted. The wheelbase would then be seventeen foot against the

prototypes nineteen, but this is cheaper than using expensive Minitrix HAA's as

the basis.

The MEA is another mineral tippler wagon, the prototypes

were built in the late 1980's and series production began in 1990. These wagons

were intended to replace the old MDV twenty one ton mineral wagons in South

Wales but have since found wider application throughout the system. The MEA

resembles the MAA but they use the shorter wheelbase chassis from redundant HBA

hopper wagon. The ribbing on the sides of the MEAs seen has been uneven with

the verticals near the centre closer together. This makes them a bit more

difficult to model than the MAA but they can run on a Peco fifteen foot

wheelbase chassis. The Peco chassis does need some of the brake gear removing

and a new long brake handle fitting but this is not difficult.

The

latest in this series of basic four wheel tipplers in the MKA, introduced in

about 1994 or 1995, these are built on ex Private Owner air braked chassis.

A half height version of the basic box body vehicle has been produced

in some numbers in the later 1990's, these are coded MFA and are used for

ballast.

In about 1999 a bogie box body wagon was introduced coded MBA,

these may be on former BBA steel carrying wagon chassis but I am not sure about

that. Four-wheeled container carrying wagons for ISO containers have been

produced from a number of British Railways wagon types. The first were based on

redundant plate wagons (of the type offered by Peco) and Lowmac vehicle

carriers.

In the 1970's experiments began using containers to carry

coal, I believe this was mainly in connection with traffic destined for

Ireland. A number of dual braked former 'ferry' plate wagons (again essentially

similar to those from Peco) had their vacuum brakes removed and fittings for

twenty foot ISO containers added. I believe these were used for twenty foot

coal containers, designed for use with standard ISO container handling gear but

lower than normal to fit within the loading gauge when sitting on a standard

height wagon. In the early 1980's some standard air braked SAA wagons were

converted to carry thirty foot coal containers. The container wagons are

discussed in more detail in the section on Unit Loads - Modern Containers, Road

Railer, Piggyback and Swap Bodies.

Fig ___ Air braked chassis

conversions

Carflats

are car carrying bogie flat wagons with a timber deck and a low rail running

along either side. They were developed for moving motor cars and saw extensive

service on the Motorail services (see Non passenger coaching stock - Motorail).

The carflats were built using redundant coach chassis are now mainly used for

commercial vehicles such as vans and are coded FVX under TOPS.

The

carflats were cheap, reliable and able to operate at high speeds, making them

well suited to Motorail duties, but they occupied a lot of siding space for a

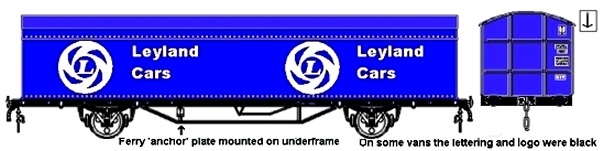

given number of cars. In 1964 British Railways and Ford jointly developed an

articulated air-braked double-decked wagon consisting of four sections mounted

on four wheeled bogies with a total length of over two hundred and ten feet and

called the Cartic Four. These required much less siding space for a given load

(typically between about a third and a half less space), some were used for the

Motorail services when demand was high. The British Railways owned Cartic

Four's (TOPS coded FQA) were withdrawn and held in reserve in the 1980's, they

are painted rail blue with no markings, there remained over a hundred Private

Owner sets operating however, mostly owned by Procor and MAT. These are TOPS

coded PQA. An etched brass kit of the cartic four is available to members of

the N Gauge society but bear in mind that just two Cartic Four units require

about three foot of siding in N.

The Autic Six (coded PJA under TOPS)

is articulated two-unit six-wheeled drop-centre and double decked car

transporter. They are about ninety two foot long, actually based on a French

design and the British version was built for Cartransport (a division of

National Freight Carriers) by Standard Railway Wagon Co in 1981. The first user

for these wagons was British Leyland but they have also been used for other

firms cars. The Lima six wheeler articulated car carrier is the closest

available design to represent these vehicles, a single Lima double-unit could

pass for an Autic Six although the side framing is slightly different.

In the late 1980's many Cartics and Autics were fitted with white or

black plastic panels on the sides to protect the cars from stones thrown by

children, some also had a curved corrugated black plastic roof added.

The Cartic Four carried about 24 cars, it was not economic for smaller

numbers as the charges were based on the hire of the vehicle not its load.

Procor introduced their Procar 80 to fill this gap, offering economic transport

of loads down to 8-10 cars. The Procar 80 is a double decked bogie vehicle

eighty three foot long, the longest non-articulated vehicle on British rails.

Renault was first user, hiring the wagons to transport cars imported at Goole.

The nearest ready to run model in N was the Ibertren bogie car carrier although

this is a little short and difficult to find these days.

The restricted

British loading gauge remains a problem for larger road vehicles such as

commercial vans and the like. These cannot fit inside the articulated wagons

and are too high to ride on the carflats. British Railways have converted a

number of Freightliner bogie flat wagons for moving these larger vehicles. This

vehicle carrying conversion is fitted with a wooden floor and has buffers at

both ends (unlike the standard Freightliner wagons). The buffer beams are above

the height of the deck so short ramps are built into the ends to allow vehicles

to be driven off over the buffers on to standard height loading bays. I believe

this is a British Railways owned conversion but I am unable to confirm details

of the livery.

The 'Comtic' is a single decked version of the Autic Six

(it has been described as an articulated Lomac) these are used for larger

vehicles and TOPS coded PKA. The comtics were first purchased by MAT-Transauto

and I believe they were introduced in 1984. Leyland/Daf used these wagons to

move articulated lorry tractor units from Leyland to the docks in the later

1980's. These could be modelled fairly convincingly by removing the upper deck

and its supporting pillars from a Lima articulated car carrier. The Autic and

Comtic wagons appeared in a number of liveries, often specified by the company

whose vehicles they carried, for example Renault had them painted yellow with

the Renault name in black on a white patch somewhere about the centre.

Inter-factory traffic has declined with changes in the motor industry

but some still remains on the railways. The Peco 'palvan' represents a design

built at Ashford in the 1960's for Ford, the model is actually rather short as

the prototype was closer in size to the Graham Farish air braked van. These

vans travelled as a block working between Dagenham in Essex and Halewood near

Liverpool. Later Ford used forty seven foot long leased wagons, developed by

Cargowaggon, these are described in the section on PO Air Braked Stock.

Fords international spares and parts movement was all containerised by

the early 1980's and so travelled on Freightliner services.

In the

1970's and 1980's British Leyland used rail for moving body pressings from the

Pressed Steel plant at Swindon to factories at Cowley (near Oxford) and

Longbridge but I have not been able to confirm the vehicle types used for this

traffic.

To cater for British Leyland traffic, specifically engines, BR

modified some of its very large four wheeled ferry vans in the late 1960's or

early 1970s (British Leyland was only formed in 1968). These were coded VQX I

believe. The sides were removed and replaced with dark blue curtain sides

(Humbrol Oxford Blue is a fair match I believe), the curtain sides had the logo

and company name on them in white. The ends and roof were all painted in a very

slightly lighter blue than the curtains. These vehicles retained the RIV

international ferry markings and fittings (the markings were moved to the ends

as shown below) and the securing lugs remained in place but I do not know if

they were used for export traffic or if they operated between BL factories in

the UK. By the early 1980's they were stored out of use.

Fig___

British Leyland (ex BR Ferry) Van

The advantage here

is that the curtain side is much easier to model than the sides and

drop-flap ventilators on the sides of the original ferry vans. A model, in N,

should be 86.5mm over headstocks with a wheelbase of 54mm. The curtain sides

should be 14mm high and wrap over the ends by about 0.5mm. The two rows of

small white rings on the drawing are the lacing rings for the sides, the upper

row were along the bottom edge of a separate short curtain near the top of the

sides. As noted by Bernard Taylor in his article of BR Ferry Wagons in

Practical Model Railways magazine (see bibliography) the long wheelbase of this

vehicle makes for problems on the tight curves of a model railway. He built his

model of the ferry van on a continental steel wagon chassis which had pivoted

axles for this very reason.

Future Developments

Predicting the future is

notoriously risky, as railway planners have found repeatedly since the early

nineteenth century. There are some trends which seem likely to continue however

such as a steady increase in mechanical handling and the containerisation not

only of finished goods but also raw materials. The steady increase in container

size has resulted in further developments in rolling stock such as the

drop-centred 'pocket' wagons used by Freightliners Ltd.

The 'Piggy-back'

wagon, carrying articulated road trailers is an idea supported by the European

Union, again the constraints of the British loading gauge has produced some

interesting new ideas for piggy-back rolling stock. One notable example is the

Eurospine wagon designed by Thrall which can carry both road trailers and

containers. Again this is not such a new idea, the Americans have been carrying

road trailers on 'piggy-back' services since the 1960's and in the early 1980's

a German firm called Talbot introduced a low-loading bogie wagon which could

carry both the tractor unit and its trailer. These latter were formed into long

rakes and used for a 'rolling-highway' service between West Germany, Holland,

Italy and Switzerland. The lorry drivers were carried in coaches at the rear of

the train. The French, who benefit from a more generous loading gauge, have

been operating special wagons carrying road trailers for several years. In the

early 1980's Procor worked on a British version but the constraints of the

British loading gauge proved too much of an obstacle, especially as road

vehicle sizes continued to increase.

First in the field was Eurospine,

a fixed rake of four articulated units each capable of carrying a low height

road trailer or a forty foot long standard ISO container. Eurospine was

developed by the American specialist company Thrall Car (who now have a

European division) and the pre-production prototype was shown to the public in

late 1996. This is not an entirely new type of vehicle, the design is derived

from an American wagon called the Fuel Foiler which entered service in the

1970's, but the British version has to contend with much tighter clearances

along the track. Services began with two sets in 1998 carrying Post Office

'Parcels Force' trailers but EWS have ordered over a hundred of these sets.

Each Eurospine unit consists of a hefty central spar with cross-beams toward

the ends to support the ends of a container and a pair of platforms mounted on

the sides to carry the road wheels of an articulated lorry trailer. The

trailers have to be lifted on by a crane, current practice favours a very large

'fork lift' type vehicle equipped with a special lifting frame in place of the

forks. John Grey offers a model of the Eurospine wagon in his etched brass

range of kits. The complete four-wagon articulated set is just over fifty nine

and a half meters or one hundred and ninety six feet long, that corresponds to

some 40cm or 15 inches in British N.

Meanwhile Freightliners were also

taking an interest in this method of transport, they worked with Frauhauf (the

road trailer builders) and Exel TankFreight (a logistics firm) to design and

produce some semi-trailers for chemicals. These are moved on redundant

low-loading wagons initially built and leased by Charter Rail for pet food

traffic under Speedlink. These wagons and road-rail tank semi-trailers were

introduced into service between the Freightliner depots in Manchester (Trafford

Park) and London. The Trafford Park terminal has been equipped with two new 23m

high transporter cranes to handle this traffic. The cranes were in part paid

for by a Freight Facilities Grant, they use standard lifting frames for

containers and a special frame with four long drop arms to lift the trailers.

Pocket wagons have a dropped section between the wheels or bogies,

similar to the old Flatrol or Welltrol wagons but with sides to the well

forming a 'pocket'. These wagons can carry taller than normal containers,

notably the nine foot six inch high types which are becoming increasingly

common on the 'deep-sea' container shipping routes.

Latest to enter the

field are Babcock (famous for their steam boiler plant) who have developed a

vehicle called the Mega 3 Pocket wagon. The Babcock wagons can carry a road

semi-trailer, two twenty foot long containers or a single road/rail swap-body.

The swap-body is a road-rail container shaped like a standard lorry

semi-trailer body which can be transported on railway wagons or on a purpose

built skeletal road semi-trailer. They are not built to ISO container

specifications (they are not the right size and they have different securing

methods), they cannot be stacked or transported on container carrying ships.

They are designed specifically to carry standard size pallets and better meet

the needs of a straight road-rail transportation service. They are a couple of

inches (about 5cm) wider than the ISO standard container, and hence run into

clearance problems on the British rail network but Freightliners Ltd. has

experimented with them.

Sketches of the Eurospine and Pocket Wagons

have been included in the section on Unit Loads - Modern Containers, Road

Railer, Piggyback and Swap Bodies.

The European Economic Community is

very interested in rail haulage for road lorries and they plan a Europe-wide

trunk rail network offering high speed transits. The British are having

difficulty deciding who might pay for the increased clearances to allow such

services in the UK. Initial estimates were that it would take £100

million to upgrade the line from Scotland to the Channel Tunnel to carry nine

foot six inch high containers and full size lorry trailers. This cost then

bloomed under Railtrack until the entire project was effectively put on

indefinite hold. At the time of writing (2003) I am not aware of any plans to

start work on this.

Europe has now evolved a plan for a Europe wide

network and the intention is that, in the future, train operating companies

will be able to operate through-services Europe-wide to increase competition

and hopefully efficiency. The plan includes considerable provision for the nine

foot six inch high containers, road trailer transporters and swap body vehicles

but as most countries on the continent meet the loading gauge requirements of

the Berne Convention work is proceeding quite quickly on this project. The

British have recently indicated that they feel it would be uneconomic for them

to provide the investment in infrastructure to achieve similar clearances

throughout the British network. Platforms would need to be cut back, bridges

and tunnels altered and the overhead catenary wires would need to be lifted to

allow European stock and engines to roam about the British system. I believe

they are prepared, in theory at least, to upgrade some lines and provide maps

for Continental train operators so that rolling stock suitable for use on

unmodified British lines can be routed through the system.

Still on the

drawing board are a number of vehicles which may yet see light of day. One

interesting idea is the self-propelled goods wagon, this is really an extension

of the old idea of the diesels parcels carriers of the 1950's and the new

parcels multiple units used for Royal Mail traffic. The new machines would be

able to operate as multiple units with perhaps three or four conventional

un-powered wagons in tow. The designs under consideration include curtain sided

pallet carriers and even hooded steel carrying wagons.

Research into

the use of aircraft style containers on the railways is also in progress,

building on the experience with the Mini-Link container and the more recent

Royal Mail containerised parcels services with their associated purpose built

multiple units. The most recent manifestation of this concept is the Minimodal

system, which uses simple square sheet metal containers, the initial standard

version has a roller shutter door in one side. These can be placed on rail

wagons or road trailers, if the door is to the side they can be loaded whilst

on the vehicle, if not they are secure from break-in when parked in a lay-by.

Quoting from Minimodal.com

The Minimodal Unit Load

The Minimodal unit load has a 2.55

metre square base, the maximum road width of a lorry, which can be rotated for

side loading from both sides and end loading - individually and in series.

Minimodal units have four way fork pockets, provision for top lift, may be

connected together to form a 7.82 metre swap body, are stackable and secure.

The Minimodal format can be adapted for dry goods, chilled produce, liquids

& gases, waste, hoppers and as a flat carrier.

Any suitably rated

flatbed road vehicle will carry Minimodal. Heavy goods vehicles can carry up to

6 Minimodal units, smaller goods vehicles can carry fewer. Standard

container-flat rail wagons can convey Minimodal by rail.

The Minimodal container services have now started, sponsored by EWS and

they could provide a useful service to parcels carriers, supermarkets and other

organisations with a high volume traffic that requires rapid

handling.

It is generally accepted that the railways now offer better

time reliability than road haulage and new investment has seen the evolution of

advanced technology solutions. Whilst it is highly unlikely that the railways

will ever regain the mass of small scale traffic they once handled they are in

a position to offer cost effective solutions to logistics managers.

^

Go to top of page

International Good Guys ~ Making the world a

better place since 1971 ~ Site maintained by

All material Copyright © Mike

Smith 2003 unless otherwise credited