Specialised Rolling Stock.

By 1850 small wagons were built with a single 'bolster'. A bolster is a

block of timber laid across the wagon to support the load, generally with a

vertical post or rod at each end to prevent the load sliding sideways. The

bolster wagons usually had a short wheelbase, typically seven foot, and a

single swivelling bolster mounted on a flat wooden deck. These were called

`single bolster wagons' and would be assembled in two's or three's or even

sixes to carry long loads such as timber and metal sections. Some wagons had

low sides (as seen on the Peco model) whilst others had no sides or ends at

all. The single bolsters were sometimes built as fixed pairs permanently

coupled together. These paired wagons sometimes had a combined buffer-coupling

between them although early designs had dumb buffers with a fixed chain

coupling. The Peco range includes a pair of single bolster wagons, but these

are on standard ten foot wheel base chassis suggesting they date from

immediately prior to World War Two. They can be cut down however and converting

these to the shorter vehicles is discussed in the section on 'Kit Bashing'.

Fig ___ Models of Great Central bolster wagons made using the Peco

kit as a basis

Modelling these and similar wagons was fully described in

Railway Modeller Nov 2001 (Traffic for Tickling Article 6).

From

about 1890 specialised vehicles started to appear in greater numbers in

response to traffic demand. Larger companies had forty or fifty different

designs of vehicles for specialised traffic but non-standard wagons were only

built in small numbers. There were large numbers of horses at work right into

the 1940's and several companies built manure wagons. The horses also required

a lot of hay and several companies built high sided open wagons to carry this

(the GWR provender wagons had higher sides than the then standard vans).

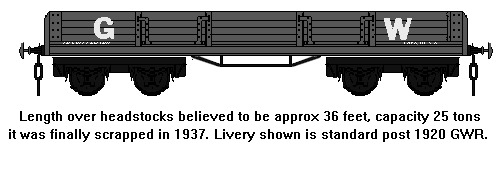

Most companies had a few

open wagons with a wooden floor but no sides or ends. They were usually fitted

with securing rings along the sides of the wood or steel chassis and were

intended to carry large objects. Introduced in the early twentieth century they

were never terribly common, from published material the North East had more

than other areas although the LMS built some of this type to carry planks of

imported timber. Most imported timber planks were Scandinavian soft wood, known

as 'deal' and these wagons were called 'deal wagons' by the LMS. British

Railways built a few of these open flat wagons (to an LNER design) in the

1950's.

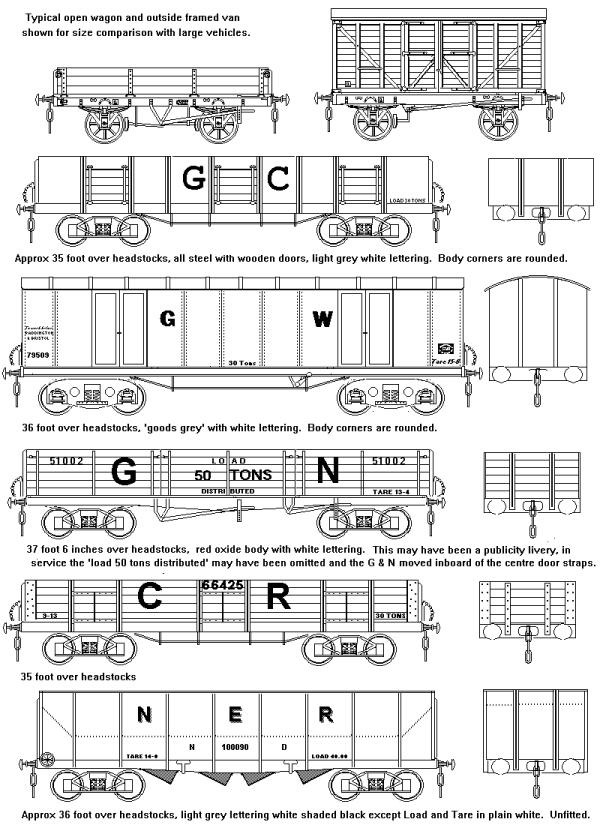

By the early years of the twentieth century some bulk trades

justified the building high capacity wagons of up to 20 tons or so. As well as

coal and coke there was bulk traffic in bricks, hammerscale, road stone, slag, oil cake,

timber, manure and grain.

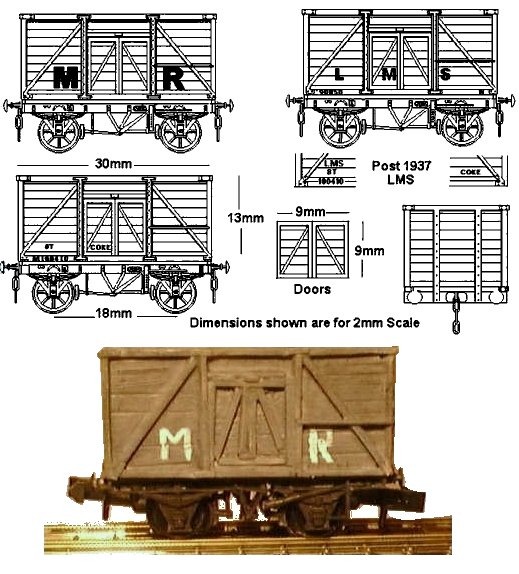

A high volume but low weight cargo was coke, large quantities of which were used

in a number of industries both as a fuel and as a raw material. Although the

value of coke was low the quantities involved justified the building of

specialised coke wagons. These resembled conventional mineral wagons but were

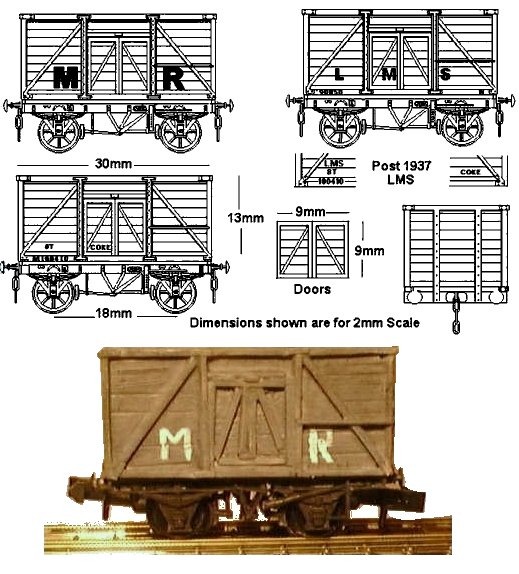

built with higher bodies. The sketch below is a Midland Railway coke wagon

design which saw service into the 1960's and possibly the very early 1970's.

Fig ___ Midland Railway Coke Wagon

Modelling these MR coke wagons in N was described in Railway Modeller

Sept 2001 (Traffic for Tickling Article 5)

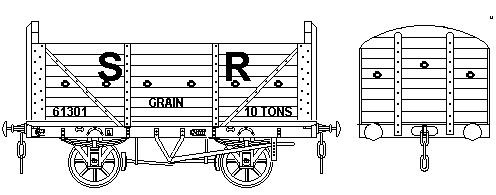

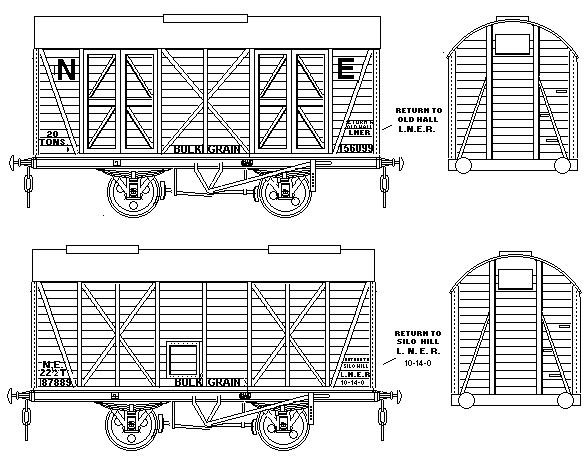

Grain Wagons

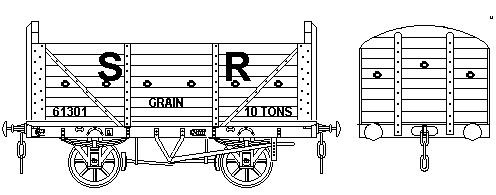

The LSWR built twenty open eight

plank ten ton hopper grain wagons with curved raised ends in the 1890's. These

were used for grain imports from Southampton and lasted forty years before

being replaced. The tarpaulin covers on these wagons would only have been

removed for loading, so a simple box of scribed card with strapping detail from

10x20 thou microstrip, end supports from 30x30 thou microstrip and a paper

'tarpaulin' would suffice. The LSWR wagons had curved raised ends, these were

replaced by the Southern Railway in the 1930's with re-built wagons with patent

tarpaulin rails.

Fig ___ LSWR grain wagon in early SR livery

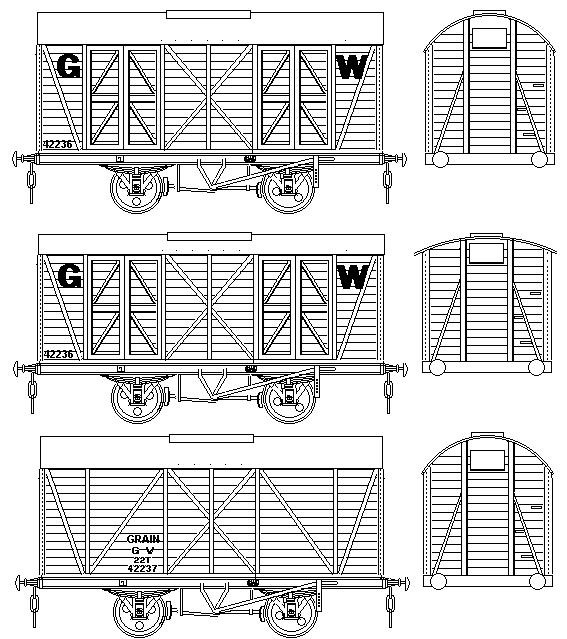

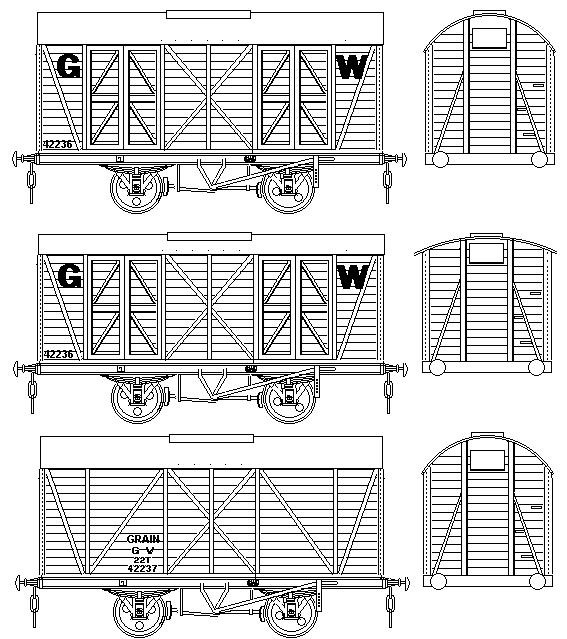

The GWR had experimented with various ways of handling bulk

grain. They had converted twenty or so ten ton standard vans for bulk grain

traffic, they then tried a 'convertible' eight ton open wagon. This latter had

a floor fitted with two hinged sections which lifted and laid back against the

ends to form a hopper. This was intended to reduce the empty wagon mileage by

allowing it to be used for normal traffic. Neither of these was a great success

but in 1927 they built twelve convertible twenty ton bulk grain hopper vans.

These grain wagons had a ten foot six inch wheel base but a body about

twenty foot long, inside was a double version of the hinged floor idea,

dropping into two discharge points underneath. The wheelbase was kept as short

as possible to allow the wagons to negotiate the tight curves in the docks.

There were two sets of heavily framed double doors on each side as well as the

grain loading roof hatches, the doors were fitted with heavy padlocks to avoid

some clot opening them when the van was full of grain. The twelve GWR vans were

switched to bulk cement traffic in the 1930's, at which time the side doors

were screwed shut and the roof profile was lowered as shown in the sketch. They

were re-converted for grain in 1940, at which time the hoppers were fixed in

place, the side doors were removed and the roof reverted to the high arched

profile.

Fig ___ GWR Grain & Cement Vans

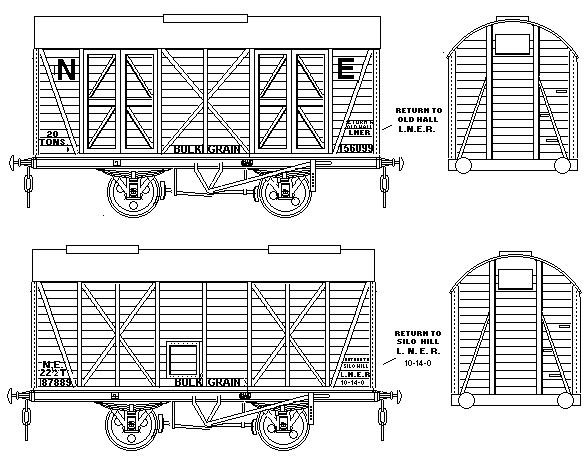

The LNER built twenty five grain vans to the original GWR

design. These vans proved popular but were seldom used for traffic other than

grain so when demand increased and further LNER vehicles were built these had a

fixed hopper and no side doors. The convertible types used by the GWR and LNER

were identical, the versions with no side doors differed only in the strapping

detail on their sides and the later LNER design had two roof hatches in place

of the original single hatch. Note the small inspection hatch on the side of

the later LNER van was fitted on one side only.

Fig ___ LNER Grain

Vans

The LMS inherited a number of bulk grain hopper wagons built

by the Midland Railway in about 1922. These were based on a standard Midland

van of the period, similar to the kit available from the N Gauge Society but

with the diagonal strap going the other way. In spite of the preference by

traders for wooden bodied grain hoppers the LMS built over a hundred grain

hopper wagons with steel bodies in the 1920's. The GWR built a small fleet of

twelve essentially similar steel wagons in the mid 1930's. Both designs were of

twenty tons capacity and retained the ten foot six inch wheelbase with the long

overhang at each end. The LMS version had external 'L' shaped strapping on the

sides whereas the GWR hoppers had smooth sides. These pre nationalisation bulk

grain wagons were used for imported grain, most British grain was still shipped

in sacks, transported in standard vans and sheeted open wagons.

Fig

___ GWR one-off, early MR/LMS and later LMS/BR and GWR/BR steel Grain Vans.

The GW wooden van was a one-off (built in 1905) but quite a few

of the MR/LMS vans were built. On the layout these wooden vans were used in the

docks at Fettling on Sea (the MR type were used in that way into the early

years of BR). The hopper discharge hand wheels are just Gimp pins (from a

sewing shop) painted black and with the rim and spokes in white. These vans all

had a single such wheel. The steel grain van models were made using the Peco

Grano long wheelbase grain hopper as a basis. This was after the possibility of

doing so had been pointed out to me by Alastair Knox of West Brent fame. These

also have Gimp Pin handwheels, but for some reason I photographed the wrong

side.

BR built their own steel bodied grain hoppers, very similar

in design to those built by the LMS although there were differences in the

outside strapping (the LMS had angle section across the curve of the roof, BR

used flat strapping, much easier to model). BR built a number of similar grain

vans on a slightly different vacuum brake fitted chassis. Modelling all these

variants is discussed in the section on Kit Bashing.

The photo below, courtesy of Dapol, shows their N Gauge BR era grain wagon.

The LMS and GWR steel grain hoppers, and their wooden GWR and LNER predecessors, remained in use into the mid 1970's and were seen all over the country, so you can add a couple of odd ones to a rake of Dapol hoppers. The Peco `Grano' is a good example of the leased wagon, introduced in 1965 and built in batches up to 1971, the first batch was built by by Pressed Steel Co. for a company called BRT (British Railway Traffic & Electric Company, formed in 1907 and bought by Procor in 1974). These were painted all over blue and were mainly leased to the Distiller Co and used for hauling barley from the South East up to Scotland for the distillieries.

Beer & Ale Wagons

Several companies built or

converted vans for 'ale' or beer traffic, these were usually called 'ale

wagons'. The beer travelled in barrels and was not liable to weather damage,

but it had to be kept cool so the rolling stock used was well ventilated. The

Midland Railway built vans with open slatted sides similar to milk vans, the

Great Eastern converted some standard vans by drilling large numbers of one

inch diameter holes in the sides and ends and the GWR used redundant cattle

trucks. Cattle trucks provided plenty of ventilation with their open upper

sides and gaps between the lower planks on the sides as described below. The photograph, courtesy of Dapol, shows their OO scale model of a BR standard cattle wagon re-branded for beer traffic.

Fig ___ Beer Vans

Livestock

Cattle trucks are called trucks rather

than vans because they were originally open wagons with timber rail sides. In

the 1890's the Board of Agriculture ruled that cattle trucks should be fitted

with spring buffers at both ends and better footholds and in 1904 rules were

introduced requiring cattle trucks to have a roof. Many companies had been

fitting a roof since the 1860's, prior to that date many cattle wagons were

open and at best had a tarpaulin stretched over the top to provide shelter. The

1904 rules stipulated a need for ventilation (the open upper sides common since

the 1850's served for this), openings to allow inspection at floor level and

that they should be fitted with falling doors to form an access ramp. The open

upper sides, usually with one or two horizontal iron bars, provided adequate

ventilation, inspection at floor level was already catered for in that wagons

had openings along the lower sides to allow the muck to be washed out and the

falling doors were already standard. Some companies interpreted the inspection

openings rather differently, leaving a gap of two or three planks in height on

the lower sides and fitting this with a railing of closely spaced vertical iron

rods. This latter approach is much more difficult to model.

Cattle

travel standing up so to prevent them being thrown about they had to be pushed

in so they supported each other. There were three agreed standard sizes of

cattle wagon, small (thirteen foot six inches long), medium (fifteen foot six

inches long) and large (eighteen foot long). By the turn of the century only

the large type was in production but this was fitted with a moveable partition

to convert it into a medium or small size. Livestock vans, along with fish and

milk carrying vehicles, were among the first goods stock to run in passenger

trains and express goods trains. Screw couplings and vacuum brakes were often

fitted to cattle wagons but there were also quite a number of unfitted wagons

in service and unfitted cattle wagons with a hand brake on one side only

survived into the 1930's.

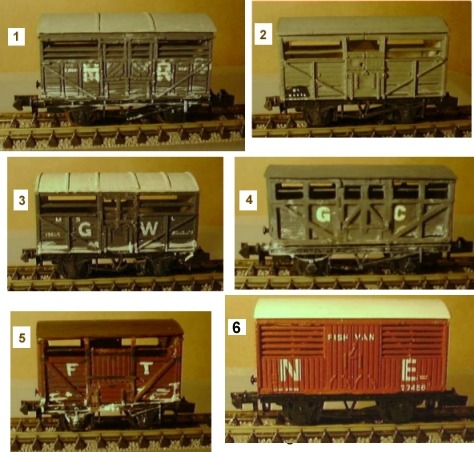

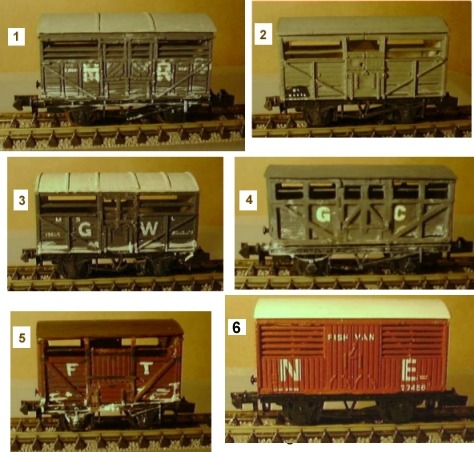

Fig___ Models of cattle

wagons

(1) Farish van in MR livery with added roof strips. (2)

Peco cattle wagon in unfitted BR livery. (3) Peco cattle wagon with added roof

strips and doors modified to represent the standard GWR design. (4) A Graham

Hughes whitemetal kit of a fitted GCR cattle wagon (mounted on a Minitrix

chassis as I made a mess of the kit chassis - This should have clasp brakes).

(5) A small cattle wagon made for a light railway layout, a shortened version

of a standard NER design (this appears to have been a commercial vehicle, used

by several companies). (6) The Graham Farish fish van looks like a goods wagon

but in practice this would most likely be part of a rake of fish vans or

possibly attached to a passenger train. The model is accurate but really should

have vacuum brake pipes on the ends and a vacuum brake cylinder mounted

underneath, it was actually a Great Northern design, to back date it just

replace the N E with G N. More information on fish traffic is included in the

section on 'Operations - Non Passenger Coaching Stock'. Horse boxes, which were

designed to run in passenger trains, were similarly classed as Non Passenger

Coaching Stock, as were 'prize cattle vans', which tended to broadly resemble

horse boxes but tended (from what I have seen) to be slightly larger.

One sometimes sees pictures of cattle wagons with white interiors and white stains on their sides caused by `lime washing' the insides of the wagons as a way of disinfecting them. The interior of these wagons should be all white and the liquid leaked out between the planks as well as through the built-in openings. There would be patches of white all over the body but mainly where there were gaps such as the openings at the bottom and around the open upper sides. This practice was banned in the 1920's, so the stains should not appear on Big Four or British Railways stock.

Perishables traffic in goods trains

Perishables, as

the name suggests, need to be transported quickly and efficiently. Milk and

fish are classic examples of this kind of traffic but as noted above these were

normally transported in 'passenger rated' stock, discussed in more detail in

the section on 'Operations - Non Passenger Coaching Stock'.

Meat,

fruit, butter, eggs, fruit and vegetables all required a lot of ventilation to

keep them cool in transit. Ordinary ventilated vans did not provide sufficient

air flow so special vans were built for this traffic with extra ventilation in

the sides and ends. Many of these vehicles were equipped to travel attached to

passenger trains (equipped with a vacuum brake and classified as XP (express)

stock). At times of high demand, such as the harvesting of seasonal fruits and

vegetables, cattle wagons were regularly pressed into service. These were often

fitted with a vacuum brake and the openings in the upper and lower sides

provided plenty of ventilation (but a tarpaulin was usually added over the top

of the vehicle to prevent pilfering). Open wagons were also regularly used for

this traffic, the load being covered with a tarpaulin or two. Some open wagons

were fitted with a raised framework to enable them to carry bulky but not very

heavy loads such as vegetables. My model, built for a light railway layout, is

a slightly modified Peco seven plank wagon kit. The model is loosely based on a

wagon built by the Great Northern railway, the GN wagon was rather longer.

Making the frame and modelling the GN wagon (without the frame) are discussed

in the section on Kit Bashing.

Fig ___ Wagon fitted with

slatted frame for vegetable traffic

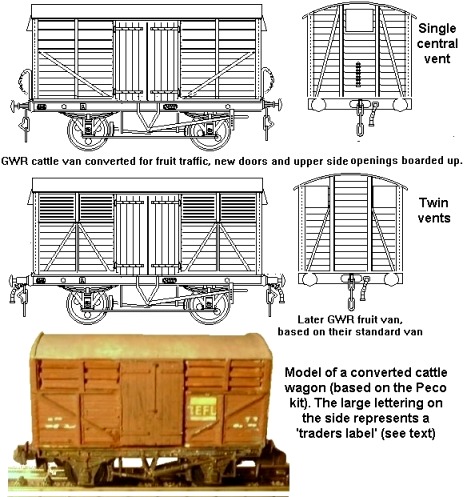

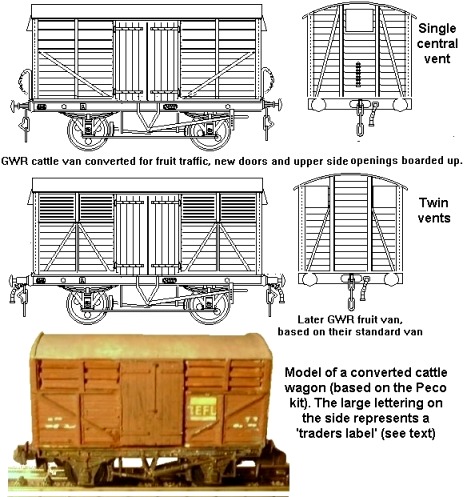

As the pattern of traffic changed over the years most

companies converted redundant rolling stock to cater for new traffic. Cattle

traffic had been in decline since the mid 1930's and the LNER and GWR had

experimented with converting cattle wagons for fruit traffic. The GWR

conversion involved boarding up the gap at the top of the side and fitting

standard vertically planked hinged doors, similar to the doors on the Peco

ventilated van. This was a successful conversion and further examples were

built by British Railways, still based on the standard cattle wagon but built

from new as fruit vans. Modelling details for this vehicle will be found in the

section on 'Kit Bashing'. The example shown is a GWR conversion in early BR

bauxite livery as it was fitted with a vacuum brake.

Fig ___ GWR/BR

fruit van conversion

The model represents a converted cattle wagon with simple 'boarded

up' upper sides, the later versions had louvers (much harder to model) and

slightly different side strapping. An example is shown in the section on Post

Nationalisation wagon development. The model is based on a Peco cattle van with

a set of doors left over from another conversion of a Peco van (actually a BR

'tin can van' conversion discussed in the Section on Post Nationalisation wagon

development). The rectangular sign on the side is supposed to represent a

'traders label', this one was actually cut from the thin paper wrapper on a pot

of herbs. Traders labels are discussed in the section on Livery.

The photo below, courtesy of Dapol, shows their OO scale BR fruit van.

Sugar

beet was produced in considerable quantities after the First World War and at

harvest time it was standard practice to ship the beets in any available open

wagons, including coal wagons, to get them to the processing plants in time.

These wagons were not sheeted over when carrying beets.

By the end of

the nineteenth century steam power was having an increasing impact on

international shipping and live beef was brought in from Ireland and the

Americas. These animals were slaughtered at abattoirs close by the ports, the

meat being forwarded by rail. Ventilated meat vans were introduced in the

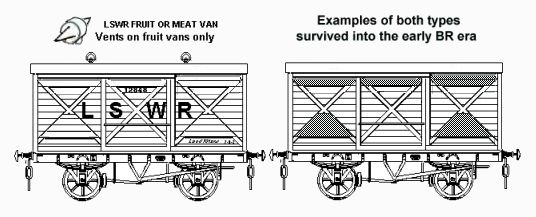

1870's and shipments of meat soon began to replace movements of live cattle

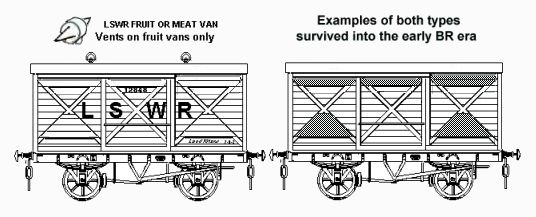

into the towns. The LSWR used a single basic ventilated van design for meat

vans and fruit traffic, both requiring similar handling. These outside framed

vans had gaps in the planking on the upper door and upper and lower sides but

these were covered by planked covers that were flush with the framing. The

fruit van had two roof ventilators, mounted on the centreline of the roof, but

did not always carry the word FRUIT on the door. These vans had lower than

normal roofs, which adds interest to a rake on a layout and some survived into

the early years of British Railways.

Modelling the more common version of

these vans (without the side ventilation, was described in Railway Modeller Jan

2002 (traffic for Tickling Article 7). To produce a meat or fruit van you

simply need to fill in the areas as shown on the sketch with Milliput and

scribe these to represent planking. The model described has a single end vent,

some of the fruit and meat vans were similarly equipped but other had up to

five vents on each end.

Fig ___ LSWR Meat/Fruit Vans

Ventilated meat vans equipped with hooks on which the fresh meat

was hung were built in some numbers, even small companies would often have a

couple of these.

With the arrival of chilled meat brought in by sea in

the later nineteenth century insulated and refrigerated meat vans appeared. The

frozen sides of meat were wrapped in Hessian cloth and stacked up inside these

vans. The GWR used a single basic design for both insulated and refrigerated

meat wagons. The N Gauge Society offer a rather neat kit of the type, complete

with transfers, but my model was made many years ago from a sanded-down Peco

'standard van' with planking scribed on the sides and end vent covers added

from scribed card bedded into Milliput. The photo was taken before the

lettering was complete.

Fig ___ GWR insulated and ventilated van

By the mid 1930's most meat traffic was carried in special

containers (coded BM) each carrying four tons of meat hanging on hooks. These

containers are sketched in the section on Unit Loads. The LNER used to see

entire trains of BM containers on special Conflat wagons travelling down from

Scotland to London, but the meat was often bruised in transit.

Bananas

became a regular cargo in the 1920's, they were unloaded from ships is an

unripe 'green' condition and shipped in specially built vans which were both

insulated and fitted with steam heating coils. The heating was applied as the

train made its way to the town and began, or accelerated, the ripening process.

The Peco ventilated van is a model of a GWR standard design dating back to the

late nineteenth century. The vertically planked doors on the Peco model were

introduced in 1927, the original design featured horizontally planked 'outside

framed doors'. The metal 'bonnet' end vents were introduced in 1912 and in 1919

some of these vans were lined with insulation to carry chilled cargo. The vents

were blanked off inside when the insulation was installed. In 1922 the vans

were modified to carry bananas which had to be heated in transit. The

insulation was retained but a new central vent was fitted to each end, and the

white spot was applied to help staff identify these converted vans. The livery

on the Peco GWR van is a hybrid, the lettering is correct for a ventilated van

but the big white spot was only applied to vans converted to carry bananas. For

a ventilated van the white spot needs to be scraped off but the remainder of

the lettering is fine. For a banana van the word 'ventilated' on the lower left

of the body needs to be changed to read 'banana van' (small white dots will do

for this).

The Peco 'Ventilated' van makes a passable BR banana van,

which was itself based on an LMS standard design insulated van derived from a

pre-grouping design which seems to have been used with minor variations by

several companies. BR banana vans had a yellow disk, eighteen inches in

diameter, with the vehicles tare weight on it in black in roughly the same

position as the GWR's white disk. The pre-grouping vans had only the top and

bottom hinges on the doors, but removing the middle pair without this being

obvious is difficult. The LMS vehicles were originally refrigerator vans with

roof hatches but with the change from water ice to carbon dioxide 'dry ice' the

roof hatches were removed. Similar vans but with a ventilator in each end were

built for banana traffic. In BR days the end ladders were removed.

Modelling the GWR and LMS/BR banana vans was discussed in Railway

Modeller Jan 2002 Traffic for Tickling article 7.

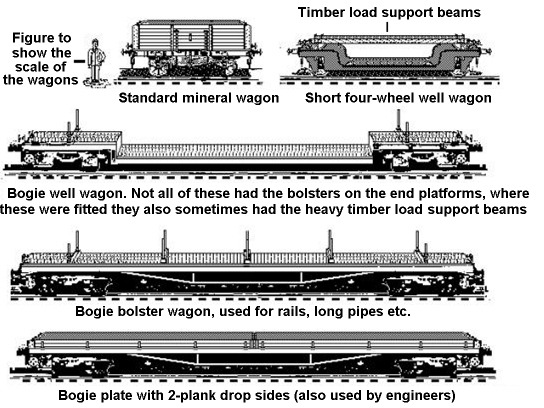

Long & High Load Wagons

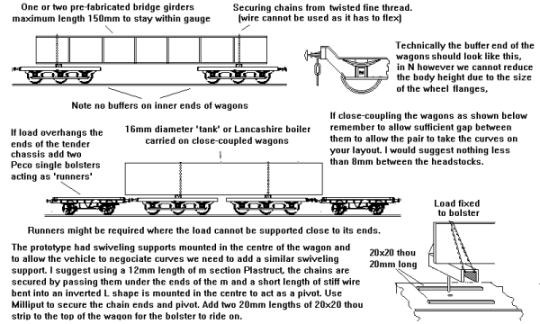

As noted above the

first solution to transporting long loads was the rake of small wagons fitted

with bolsters. Introduced in the 1850's they were still being built in the

early 1960's but fell from favour soon thereafter. As iron and steel technology

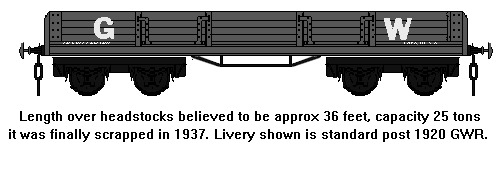

improved wagon size was generally increasing and by the 1890's longer loads

were becoming more common, among them long rail lengths for which long wheel

base and bogie bolster wagons were built. 'Long rail' and 'Plate' wagons were

low sided long wheel base vehicles, designed to shift thirty foot lengths of

rail, large metal sheets or bundles of rods. They were also often used to move

agricultural machinery and smaller road vehicles as the drop sides meant they

could be relatively easily loaded from the side and did not require special

end-loading facilities. There is a photograph in R. J. Essery's book 'Midland

Wagons Volume One' showing a Rolls Royce motor car chassis being crane lifted

onto such a wagon in about 1920. The Peco range includes a long wheel base

plate wagon based on an LNER/LMS design dating from the early 1940's. The

chassis requires some work to improve this model but it can also serve as the

basis for a number of older designs, details will be found in the section on

'Kit Bashing'

The four wheeled plate wagons were often fitted with

bolsters and put into service to augment the existing single bolster wagons and

permanently coupled single bolster pairs. Again these can be modelled using

existing RTR wagons or kits, most of mine have been made using the Peco plate

wagon as the basis.

Fig ___ Peco Plate wagon converted into a Great

Northern twin bolster wagon.

Modelling this vehicle was described in Railway Modeller March

2001 (Traffic for Tickling Article 12). The 'chains' are made up from two

strands of 5 Amp fuse wire twisted together.

'Pipe' wagons were

built to carry clay drainage pipes (packed in straw). These were long four

wheeled wagons with four or five plank sides and a wheelbase of about twelve

feet. Parkside Dundas offer a kit of a 12 foot wheel base pipe wagon, a pre-war

LNER design which remained in service into the later 1980's. Some were still in

use in departmental service in the late 1990's.

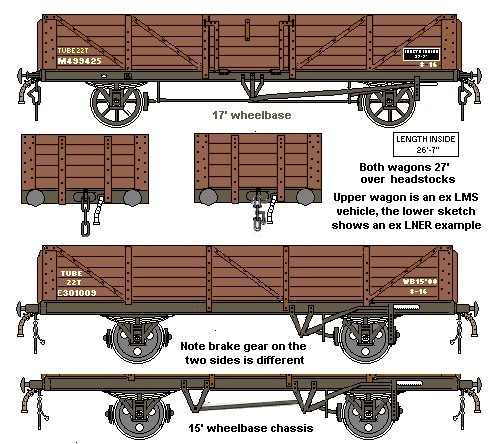

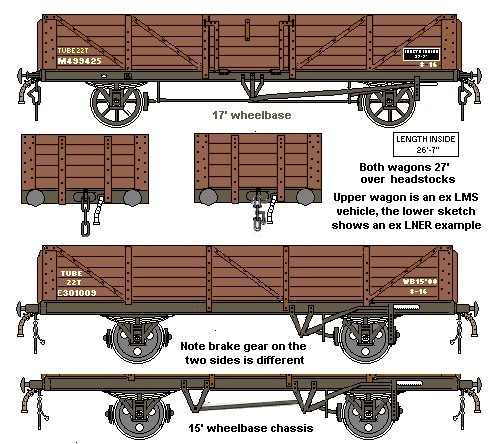

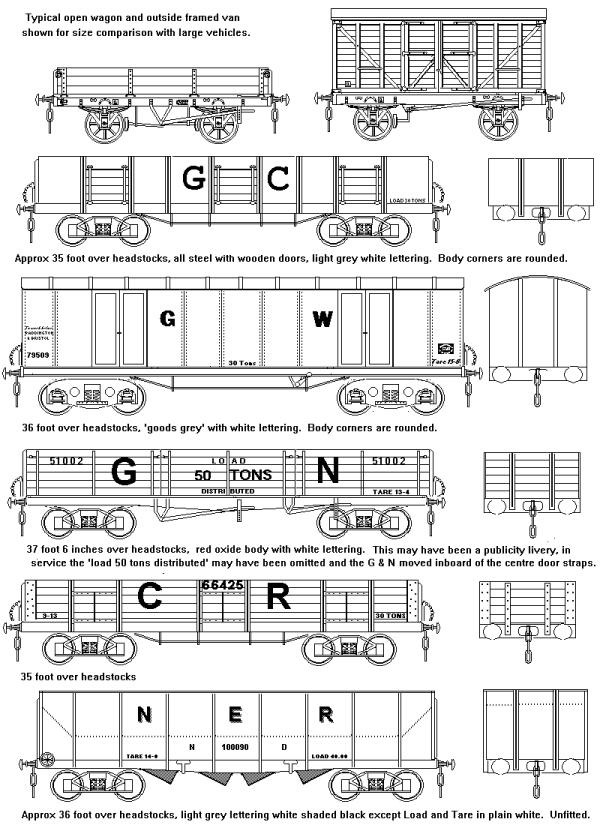

Even longer high sided

wagons were built after the First World War with wheelbases of up to twenty

foot. These were usually called 'tube' wagons (the Peco 'tube wagon' is a model

of a British Railways wagon built in the 1950's for use on train ferries to the

continent). The GWR 'tube' wagon, coded Open C, was a four plank design on a

fifteen foot wheel base, the LMS had a five plank wagon on a seventeen foot

wheel base with a central door and the LNER built some wagons on a fifteen foot

wheelbase with no side door. Modelling notes for GWR, LNER, LMS and British

Railways (steel-ended) tube wagons have been included in the section on 'Kit

Bashing'. Note the asymmetric brake gear shown on the ex LNER wagon was their

standard design for vacuum braked stock and was adopted by BR.

Fig

___ Pre-war tube wagons in BR liveries

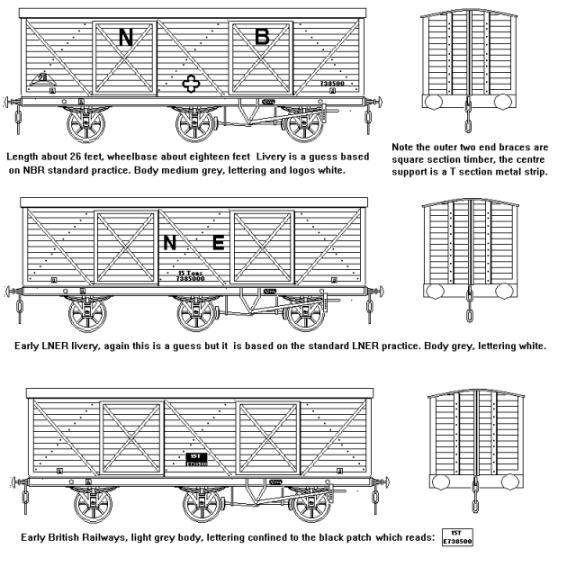

Where long wagons were required to carry heavy loads a six

wheeled chassis was used although these were never really common. I have

described my way of modelling these chassis in the section on Kit Bashing. Some

of these six wheeler vehicles had surprisingly long lives, and a few of these

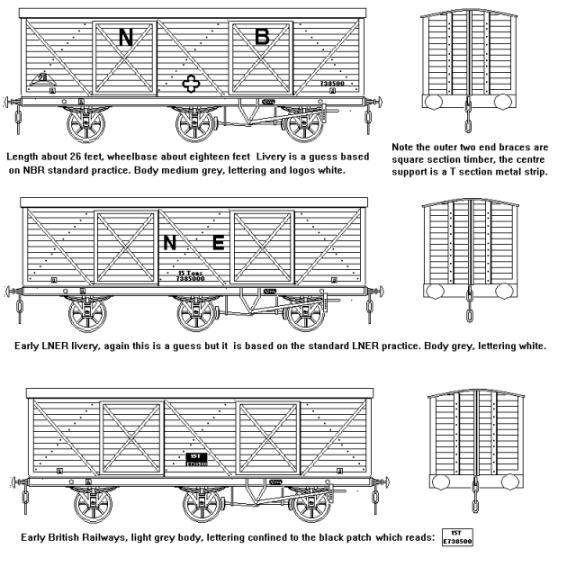

older vehicles survived into the 1950's. The six wheeled van shown was built by

the North British Railway before the First World War and lasted into the early

years of British Railways fifty years later.

Fig ___ North British

Railway 15 Ton Van

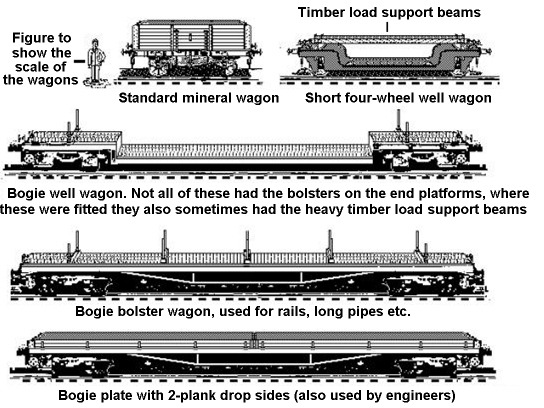

For carrying items that were more than about thirty feet long

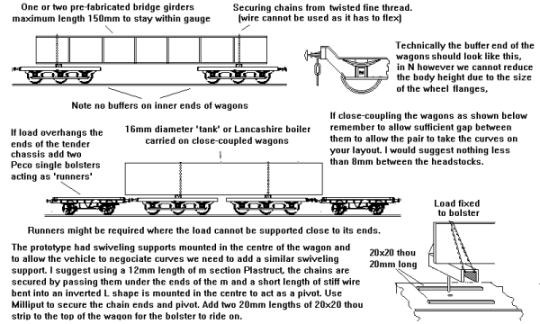

bogie wagons were required. Most common were the bogie bolster wagons,

generally these carried four or five bolsters. These long wagons were in use by

the early twentieth century and bogie bolsters were built with up to seven

separate bolsters mounted on a single body. Usually the bolsters were removable

and there were often more mounting points than bolsters, allowing different

arrangements for different loads. Bogie bolster wagons were built in some

numbers just before the First World War and a number of fairly standard lengths

were established. Shortest were the twenty ton wagons which were typically

thirty five feet long, the thirty ton wagons were generally about forty five

feet long and forty ton wagons tended to be fifty to fifty two feet long. The

GWR built a few seventy foot long bogie bolster wagons in the pre-grouping era

but these were of course very restricted in routes due to their length. British

Railways built a number of sixty two foot long bogie wagons for carrying

lengths of rail coding them Borail. These were always assigned to the

departmental stock and were not used for commercial loads.

By the late

1960's bolster wagons of all types were used almost exclusively for steel

traffic. The single bolster wagons and pairs were phased out by the mid 1970's,

the four wheeled bolster wagons lasted only a few years longer and by the late

1980's only the bogie types remained in service. On modern stock steel bolsters

which fold down into the floor have been provided in some cases, these also

help to dissipate heat from freshly milled steel ingots.

The same

chassis were also used for bogie plate wagons although these were not so

common. Most bogie plate wagons were built with drop down sides, typically two

planks high and arranged in two half-length sections. Some of the bogie

bolsters were subsequently converted to plate wagons and on these the sides

were usually fixed. The N Gauge Society offer a plastic kit of an LMS

five-bolster bogie wagon which saw service into the 1970's. Several of these

wagons were converted to plate wagons with fixed sides two planks high by both

the LMS and British Railways.

Any items larger than about fifty foot

long or over eight feet wide were classed as 'special traffic' because of the

danger they might foul stock on adjacent tracks when in transit. These items

were rather rare in practice and would usually be worked through the system

during a low traffic period, usually over a weekend. Anything wider than about

eight foot presented a real problem on the railways, laid flat it would be

likely to foul stock on adjacent tracks and line side equipment, on end it

would foul bridges. To allow larger sheets of metal to be carried some four

wheeled and bogie plate wagons were fitted with a wooden trestle so the load

could be supported diagonally. This allowed loads of up to about 12 feet wide

to be carried.

Fig ___ Peco plate wagons converted to trestle

wagons

Modelling the BR and four-legged NE trestle

wagons was described in Railway Modeller March 2003 (Traffic for Tickling

Article 14). The model of the three-legged type shown here was an earlier

attempt and not quite up to the same standard. It was based on a drawing in

Peter Tatlow's book on LNER wagons (see Bibliography)

One

option for carrying tall loads was of course to lower the centre of the vehicle

and drop centered or 'well' wagons were built on both bogie and four wheeled

chassis One specialised variant on this theme were the wagons built to carry

road vehicles, these are discussed in more detail below.

The more

general purpose drop centre vehicles usually called 'trolley wagons' by

railwaymen. Unfortunately a lot of these wagons had an open framework with no

floor in the centre well, making a model of an unloaded vehicle a rather

difficult proposition. Most of the official photographs of these wagons are

taken from the side, so the floor is not visible, a little research is

therefore required when selecting a prototype.

Fig ___ Long and Low

Centre Wagons

Fleishmann offer a continental drop-centred four wheeler in

their range which, although it does not resemble any particular British design,

can be pressed into service. Filing the sides of the floor plates so they are

parallel helps and for a British wagon the hinged side stakes should be

removed.

These vehicles are not impossible to model, especially if one

take a freelance DIY approach rather than trying to produce an accurate scale

replica of one of the prototypes. On the plus side they were often fitted with

removable longitudinal beams, mounted on raised bolsters on the end platforms.

Adding these beams gives a box structure which should cope with the average

model railway handling. Modelling drop centre four wheeled wagons is considered

in the section on Kit Bashing.

My model is based on the smallest type I

could find, a 1930's LMS design, as I wanted the look of the thing but did not

want it to take up a disproportionate amount of room on the layout. The

prototype was equipped with two heavy longitudinal baulks, as shown in the

sketch above, although these would not have been carried if, for example, the

load was a caterpillar tractor of some kind. My model was built with removable

timber baulks, one pair loosely wrapped in chain (set solid with glue), the

other pair with a ships propeller mounted between them. This was never a great

success as an idea as I failed to make provision for mounting the baulks using

locating pins and holes in the end supporting timbers, as a result the load

tended to wander off to the side as the wagon vibrated. I intend to repaint the

model in early BR grey and will probably just glue a pair of timbers in place.

Fig ___ Relatively short well wagon model

In the 1930's large steam powered and later diesel

excavators and bulldozers appeared. The railways had already built bogie and

four wheeled wagons with a very low dropped centre section to carry very large

loads such as boilers. The centre was dropped as low as possible, so it was not

practical to add ramps for end-loading but they could be used for the new

machines as their caterpillar tracks allowed them to be loaded from the side

and turned on the wagon itself. The low centred bogie wagons were called

Weltrol (well-centred trolley wagons) by British Railways and when fitted with

a trestle they became 'Trestrol'. Fleetline offer a kit of a bogie well wagon,

resembling a GWR design dating from the 1930's but running on Graham Farish

diamond frame bogies. They also offer the same wagon fitted with a trestle for

large plate loads. The N Gauge Society offers an excellent plastic kit of an

LMS bogie well wagon and the kit includes an set of etched brass trestles. In

the Bachman range is a 'fifty two foot' bogie well wagon which scales out at

about forty eight foot in British N. This model was originally supplied with a

'rocket load' but it is now also (I believe) available empty. This model,

although a few millimeters short, resembles a British 'Warwell' built in the

Second World War to carry tanks. These vehicles survived well into the British

Railways era, some being converted to carry steel by fitting them with raised

bolsters in the centre well. Parkwood models have now released kits for both

the Warwell and Warflat wagons (the latter are discussed below).

Heavy Loads

In the early days of the railways two

tons was a substantial load. By the 1840's eight ton loads were not uncommon

but anything over about fifteen tons was really too heavy for the track. By the

1850's solidly built six wheeled 'boiler trucks' were built to carry loads of

twenty tons and by the mid 1860's eight wheeled boiler trucks were built that

could carry forty tons. By the 1890's the use of armour plate in battleships

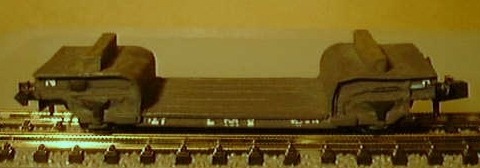

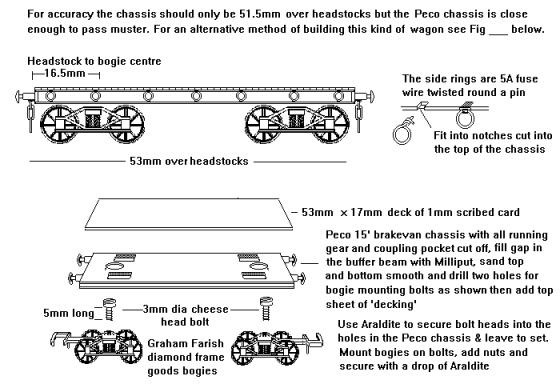

and heavy castings in industry had increased for which the railway companies

built increasingly heavy wagons. The example shown below was built by the Great

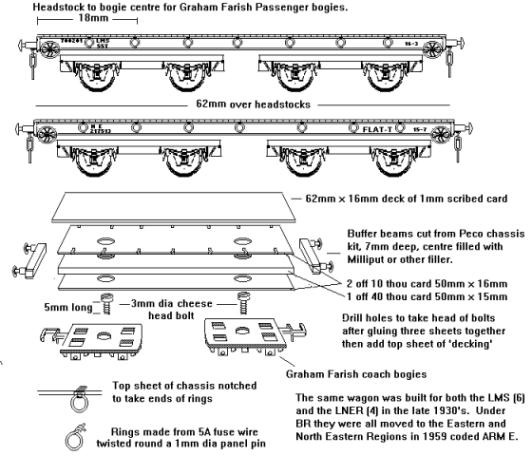

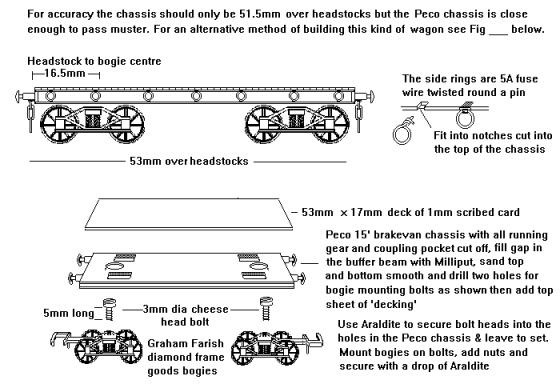

Central Railway at about the time of the First World War. This vehicle is a

practical proposition for the novice model maker, the chassis is a Peco brake

van chassis with the foot boards, running gear and coupling pockets removed.

The decking is a sheet of 1mm scribed card and the wagon runs on standard

Graham Farish diamond frame goods bogies.

Fig ___ Great Central/LNER

Armour Plate Wagon

For larger heavy items the railway companies built articulated

sets of heavily framed wagons with a total length of up to fifty foot. These

could be separated into individual wagons and used to transport longer loads,

but used in that way they would run as special traffic to avoid the risk of

accidents to line-side fixtures or stock passing on an inner curve. They were

usually called 'boiler trucks' by the railways but different companies had

different telegraphic codes (the GWR called the Pollen for example). No models

are commercially available for these wagons but a pair of Graham Farish tender

chassis could be used to produce something essentially similar. If you wish to

work the pair empty I suggest making up a couple of heavy timber beams mounted

on and chained down to the pivoting supports. Beams such as these were

sometimes fitted to these wagons to support a boiler or similar load.

Fig ___ Heavy Boiler Trucks

From the middle of the First World War the Army required railway

wagons to transport their new tanks but driving one of these over the end of a

standard design wagon in an end loading dock would exceed the maximum permitted

axle loading. To cater for this traffic the railways built, with Government

financial assistance, a number of bogie vehicles with supporting jacks built in

to the ends. These are usually referred to as 'rectanks', their standard

telegraphic code name. These wagons had a slightly dropped centre section with

the ends angled upwards slightly to the buffer beam. This makes them difficult

to model. Another military design from this era which ended up in general use

was the 'warflat', which did not have the dropped centre. During the Second

World War the tall American tanks presented a problem so a new design was

introduced. This was the warwell, a drop centred wagon with ends that curved up

to a flat section over the buffers. The Parkwood models range includes a kit

for the warflat and warwell wagons but I had a couple of Roco fish-belly wagon

(reference number 2352S) which I used to represent the warflat vehicles.

Warwell and Warflats remained in service well into the British Railways era.

Some of the shorter warflat wagons, only thirty four feet over headstocks, were

eventually converted to heavy strip coil carrying wagons, coded Coil K.

In 1926 the Electricity (Supply) Act was passed, which lead to the

development of the National Grid. This brought a requirement for large

electrical transformers and the railway companies built several special wagons

to transport these. The early transformers were of moderate size and the wagons

built to move them were roughly the same size as standard wagon. They usually

had a well or dropped centre section to accommodate the tall transformers

within the loading gauge. The size of transformers kept increasing, and in the

years before World War Two increasingly larger vehicles were built to move

them. Some of the later designs were heavily built contraptions with heavy I

girders running between six wheeled bogies, similar to the earlier wagons

developed for large naval guns and the like. These would be rare and as far as

I am aware there are no kits or suitable ready to run models available.

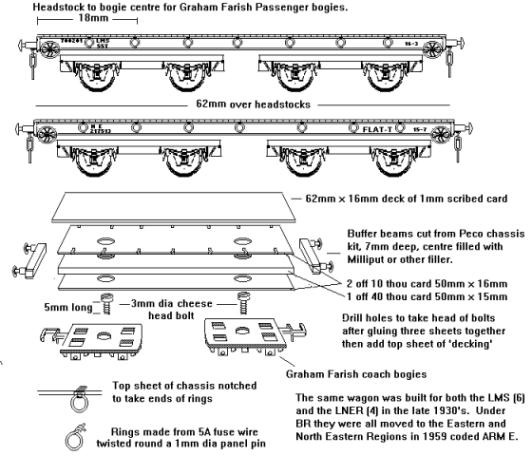

As the rearmament of the later 1930's gathered pace more armour plate

carrying vehicles were required. The LMS and LNER shared a common design twenty

four foot over headstocks and running on six foot wheelbase bogies. Introduced

in 1937 these fifty five ton wagons also carried billets of steel, heavy

castings and the like. British Railways built more wagons to this design and

also built a number of similar but longer wagons. These were still rated at

fifty five tons but they were thirty foot over headstocks and ran on eight foot

wheelbase bogies. These longer wagons were fitted with oval buffer heads.

Both types had a flat planked wooden deck and a simple I section steel

frame running on six foot wheelbase bogies. You could build the chassis using

two strips of Plastruct I section for the sides, glued to the underside of a

rectangle of 1mm scribed card for the floor, this however makes fettling the

buffer beans slightly more difficult. The generic coach bogies offered by

Graham Farish can be used at a pinch. The approach shown below works (I have

built bogie wagon chassis in the same way in the past) and results in a

stronger joint for the bogie mountings.

Fig ___ Armour Plate

Wagons

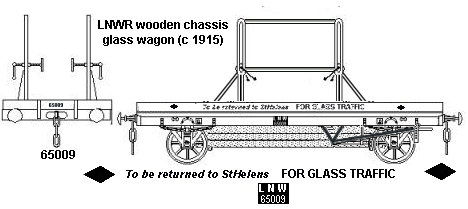

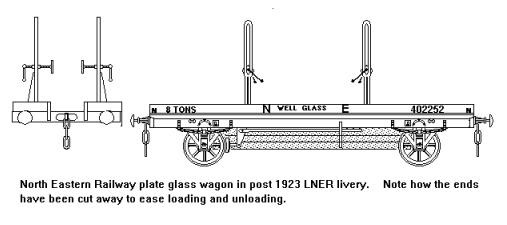

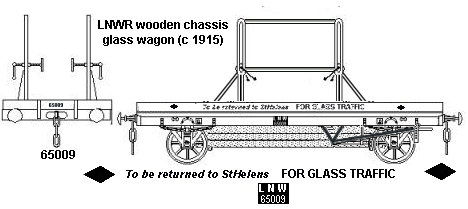

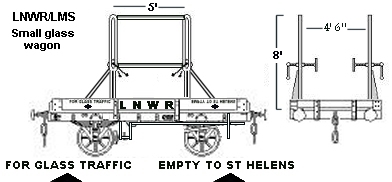

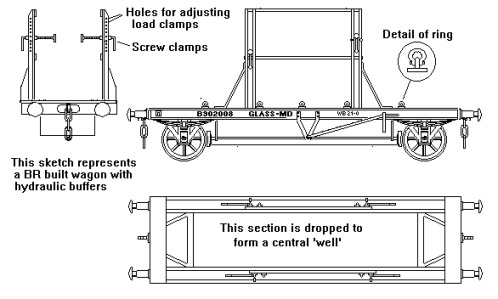

Glass Wagons

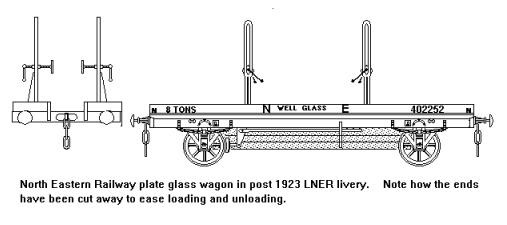

Special wagons with lowered centre

sections or 'wells' and supporting side frames used for carrying large sheets

of plate glass and larger ships propellers appeared in the 1880's. These wagons

were never very common but being little used they tended to have a long life.

The Great Eastern built only two glass wagons, one in 1899 the second in 1914,

but both survived into British Railways ownership. Plate glass was an expensive

item, shipped packed into flat wooden cases. The NER glass wagon shown below

dates from 1896 but remained in use for many years, the supports stood about eight feet above the top of the chassis solebars, the sketch shows the vehicle in its post-1923 LNER livery (for modelling details see the section on

Kit Bashing).

Fig ___ Great Northern/North Eastern Railway glass

wagon

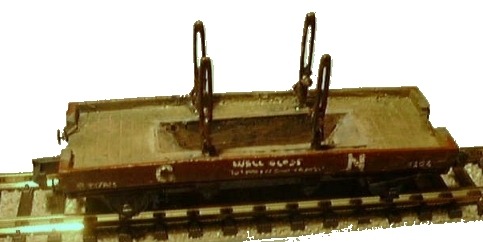

In transit a chain was added over the top of the load, secured to the side supports, when not in use these chains were left across the ends between the frames. As the load on the models were to be removable the chains were attached to the case. My model was made for a kiddie and had a removable load, as a

result I did not take as much care as I might have when making the well. On the

model shown the well is rather short, to make sure it did not foul the axles,

if care is taken, and the floor of the well is either sloped or stepped at the

ends a more accurate well can be made.

Fig ___ GN glass wagon

model

The LNWR operated some essentially similar wagons, although the brake gear was different (still operating on a single wheel on each side) and there was no cut-away at the ends. The supports were again about eight feet tall from the solebars (just over seven and a half feet above the wagon floor), and I believe they were closer together than on the GNR wagon (I could be wrong on that). On the LNWR wagon the supports had L section cross-bars at the top and bottom of the loops and diagonal supports at the base of the loops leading toward the wagon ends. As my model was for a child I felt these would be too vulnerable so he got the GNR version. The only photo I have seen of these LNWR wagons was captioned that they were withdrawn shortly before the grouping but I think that was a particular batch and similar wagons with a metal 'well' may well have been built after that time.

Fig ___ LNWR glass wagon

The LNWR also adopted a useful conversion of a one plank wagon, fitted with the same design of frame (again with cross bars at the top and bottom of the loops) and this represents a simple conversion to a Peco bolster wagon. The original design used a long-lever brake, operating on one wheel on each side, however as some of these short glass wagons, first introduced in the 1890s, survived into the LMS era you might get away with unaltered Peco brakes for a refurbished wagon. As I understand it the standard glass case was eight feet high and up to three feet thick (although most would be only about a foot thick), so these wagons had a thinner than normal floor to keep within the loading gauge.

Fig ___ LNWR short glass wagon

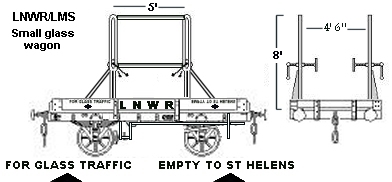

The LMS/LNER selected a joint standard design of unfitted glass wagon,

following established practice these had a sunken well in the centre section

and metal frames fitted with adjustable screw-clamps to the sides to support

the load. The British Railways plate glass wagon design was identical to this

twenty foot wheel base LMS/LNER vehicle.

The design of this

LMS/LNER/British Railways glass wagon makes it tricky to model but I have

included some ideas on this in the 'Kit Bashing' section. Glass wagons were not

numerous, but one on a layout would be acceptable, more if you have a glass

factory on or near your line (see Volume Two - Glass Works for details of

modelling these establishments). They were also used for occasional unusual

loads where their dropped centres were an advantage, such as steel sections and

coal mine pit-head winding wheels. There are photographs in various books of

British Railways wagons being used to move large metal rings with gear teeth on

the outside edge as part of a special train, this was actually a dismantled

cement kiln being moved from one location to another.

Fig ___

LMS/LNER/British Railways glass wagon

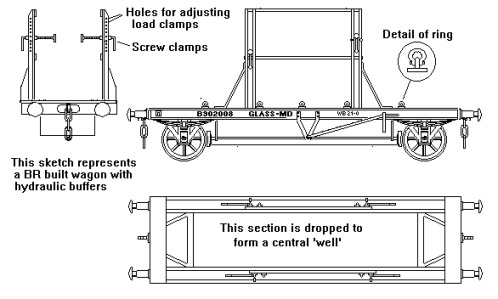

Wagons for Road Vehicles & Farm Machinery

Standard horse drawn delivery wagons and the like could be moved on any

open vehicle long enough to accommodate them. Most were shipped singly and

carried on flat wagons of typically of ten to twelve foot wheelbase. When for

example the army needed to move a number of such wagons bogie flat wagons were

used.

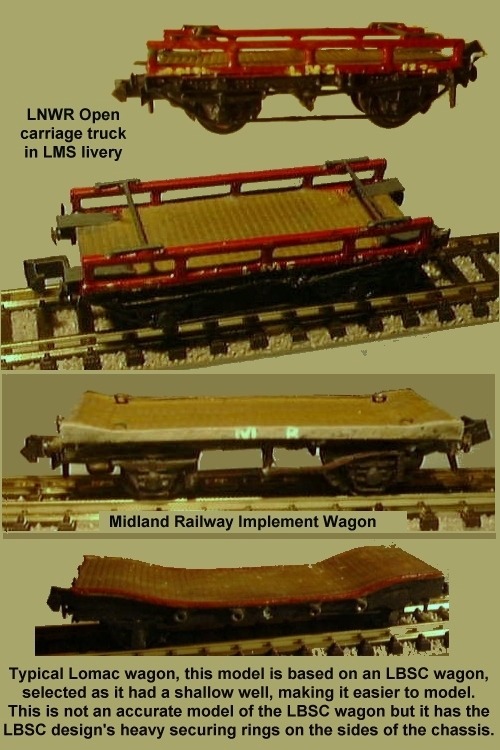

Wagons with low centre sections are generally called 'trolley

wagons', they first appeared in the 1870's and were used for carrying larger

road vehicles, farm machinery, boilers and other large loads. Depending on the

intended load these were called carriage trucks, implement wagons, machine

trucks, road vehicle wagons, furniture van trucks and boiler trolleys.

In practice those intended for commercial wheeled vehicles and

agricultural machinery were used on an as-required basis, depending on the size

of the load. Those intended for private carriages, and later motor cars,

usually had bars across the vehicles. In many cases these consisted of a timber

beam with a steel rail running along the top. The carriage or car was secured

to this bar using leather or heavy webbing straps. The example shown below is

an LNWR vehicle and this was slightly different. The loops that look like hand

rails on top of the side rails were ratcheted guides, in which moveable

brackets were fitted, to which the straps were attached. The cross-bars on the

model are tucked under the loops for strength, on the prototype these were bent

down at each end and fitted into holes on a steel plate. The steel plates were

fitted at each end of the side rails and extended for about a third of the body

length. The plates were therefore rather longer than the ratchet loops. The

securing straps are not modelled, partly because I was lazy but partly because

the wagon usually runs with a small car (from a Christmas cracker) as a load.

The straps could be represented using narrow strips of paper (about 0.75mm

wide), on this prototype they were a very pale colour, possibly white.

Machinery trucks in contrast relied on chains or ropes attached to heavy metal

rings attached to the floor, or occasionally to the sides of the solebars. Fold

down flaps were often fitted which bridged the gap over the buffers, so the

load could be manoeuvred onto the wagon in a special 'end loading dock' or

'carriage shoot' (discussed later under Railway Company Goods Facilities). On

some vehicles the buffers were covered by a fixed metal hood serving the same

purpose.

These vehicles sometimes had smaller than normal wheels and a

lower than normal floor, however they had to buffer and couple with standard

wagons so the ends were of normal height and the floor sloped down forming a

'well' in the centre. Where the intended load was not particularly large, such

as most farm machinery, the dip in the centre of the wagon was not very

pronounced. Modelling these vehicles is not difficult providing one is prepared

to accept a slight compromise in the design and this is discussed in detail in

the section on Kit Bashing.

Where the dip required was greater a longer

wheelbase was employed, allowing the ramped ends to be at a suitably gentle

angle. Models of these long wheelbase low centred vehicles (usually called

Lowmacs as an abbreviation for Low Machinery Wagons) are available from

Fleetline (a white metal kit) and N Gauge Society (a plastic kit). The

Fleetline 'Lowmac' is a British Railways built wagon but closely resembles

Great Western Railway and Southern Railway vehicles dating from the 1930's

(basically similar vehicles were in use from the 1890's). The N Gauge Society

kit represents a one-off vehicle built by a pre-grouping Welsh company.

Building a model of an LSWR vehicles of similar appearance is discussed in the

section on Kit Bashing

Fig___ Carriage truck, 'implement wagon' and

Lowmac models

The photo below shows a

Cheshire Lines Committee 6 wheeled furniture van truck carrying its intended

load. Note the van is actually horizontal when loaded, the apparent dip to the

rear is due to distortion caused by using a macro lens on a cheap camera (I

didn't have the model to hand to re-photograph).

On the model the

sides are a constant height, forming a distinct well in the centre. This was

common practice up to the early part of the twentieth century but later designs

had the sides cut down following the contours of the floor and forming a slight

lip at either side of the well. This model was based on a drawing which did not

make it clear which kind of side was used, however as it required a removable

load, the higher sides were more appropriate. Modelling the van load is

discussed in the section on Cargo & Wagon Loads.

The floor of these

wagons was usually fitted with securing rings along the sides, examples were

built with four, six or eight such rings, and set into either end was a pulley.

Horses cannot push using standard harnesses so to load the van onto the wagon a

rope was taken round the pulley at the far end of the wagon, allowing a horse

to be used to pull the van onto the wagon.

From about 1900 smaller road

vehicles and private motor cars were moved in vans fitted with doors at the

ends, these were usually called 'Covered Carriage Trucks' or CCT's. These CCT's

were intended for private carriages and motor cars and hence would often be

required to travel attached to passenger trains. They were therefore often

classed as 'non passenger coaching stock' and as such were painted in

simplified coach livery. Some of these were quite small, the Midland Railway

and later the Great Western Railway both built CCTs with a ten foot wheel base.

The small pre grouping vehicles lasted in service into the late 1930's, the

later Big Four designs remained in use into the early years of British

Railways.

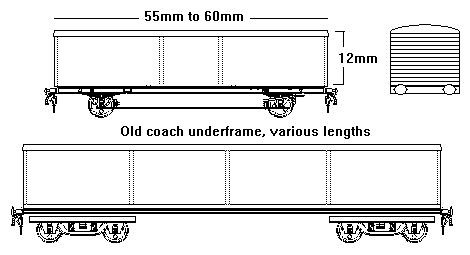

With the increase in motor car production in the 1920's more

Covered Carriage Trucks were built and the wheelbase tended to increase. The

GWR built some longer wheelbase vehicles which they called Damo B (ten built in

1925, twenty foot over headstocks), Damo A (fifteen built in 1925 with another

twenty in 1929, thirty foot over head stocks) and Asmo (one hundred built in

1929/30, thirty three foot over headstocks). Although all three could be seen

in passenger trains not all were piped for vacuum brakes and they were classed

as goods stock by the GWR. P D Marsh offer a white metal kit of an SR utility

van which fits onto a modified Peco long wheelbase chassis. The kit is supplied

alternative end doors for the CCT version. Modelling various CCT's is discussed

in the section on Kit Bashing.

Fig ___ Covered carriage truck

models

The GWR 'Mogo'

motor car wagon (built from 1933) was a standard GWR van fitted with new ends

comprising two hinged doors and a drop-down section at the bottom, this can be

easily modelled using a Peco or P D Marsh ventilated van kit. My model is based

on the Peco kit, I carved and sanded the ends flat, scribed in planking detail

and added strapping from 10x20 thou strip. The P D Marsh kit can use new ends

made up from 1mm scribed card and microstrip details. Mogos were also used for

conventional traffic the vehicle securing equipment being stored inside the

van. The Midland Railway covered carriage truck started life as a Peco

'standard' van kit, new sides were added, recessed to allow the framing to be

added using strip.

During the First World War the railways moved

numbers of new aeroplanes in kit form. The fuselage would be shipped separately

from the wings and usually without the engine. The railways built and converted

a number of vehicles for this work including flat wagons on redundant four or

six wheeled coach chassis and CCT type vans. The vans were often marked

Aeroplane Van although they could also be used as CCT's. My aeroplane van model

was made for a 1920's light railway, it is based on an NER design but I needed

it in a hurry so I simply modified a Hornby Minitrix long wheelbase van, this

has the correct roof profile but is rather too long. A more accurate model can

be made using a cut-down Peco pallet van with the ends sanded flat and detailed

with strip and new sides from planked card.

Fig___ Aeroplane van

(freelance but based on an NER design)

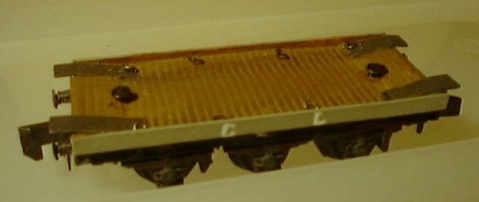

Where cars and light commercial vehicles were moved

in bulk, for example van chassis being shipped to the factory where the body

was added, the pre-war companies used old coach underframes with the body

removed and a simple wooden floor added. The LMS converted a lot of old Midland

Railway coach underframes to this use in the later 1930's. These vehicles offer

a possible use for Lima Mk.1 British Railways coaches which were under scale

length (about 57 foot instead of 62 foot)). You need to cut away the battery

boxes from the underframe trussing but this is not too difficult. If you have a

spare Farish 'suburban' coach underframe the job is even easier. The battery

boxes need to be cut from the underframe (this is easy as the frames can be

removed and the plastic is soft). I have not yet found a good illustration

showing the deck of these vehicles but I understand from correspondence with

members of the uk.railways newsgroup that the deck was made up of wooden

planking and securing lugs were fitted to the sides. These lugs were used for

straps which were passed round the axles of the cars (this was back when cars

had axles of course) Later BR built examples had channels in the deck and no

apparent lugs for securing the cars in place. All that is required for the body

is some Slaters 1mm scribed card for the floor and plastic card for the low

sides, for the later types with the channels in the deck three strips of

planked card laid onto a sheet of 10 thou card would serve rather well.

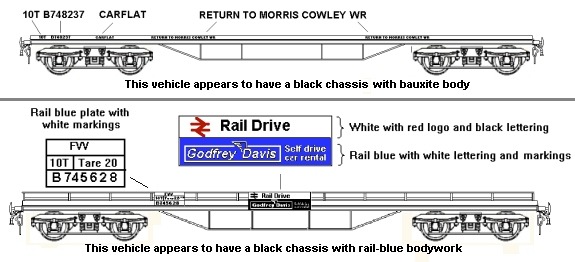

The Big Four had various telegraphic code names for these wagons but from about

1952 they were all coded Carflat and BR built further examples both for

transporting new cars from the factories and for moving private vehicles (ie

the Motorail service). Motorail services allowed people to take their car with

them on the train to save driving long distances. These latter services are

discussed in the section on Freight Operations - Non Passenger Coaching Stock.

The Motorail vehicles had a low side rail, this can be modelled using

brass rod or (if feeling lazy) by using thin brass rod for the rail and OO

scale brass handrail knobs for the supports. In the early 1980's Geoffrey Davis

rent-a-car also used carflats built for the Motorail service to move their cars

about the country (I was not able to find out when this traffic started or

ended however).

Fig___ Bocar for new cars (coded carflat) and a

Geoffrey Davis rent-a-car carflat

In the 1960's, 70's and 80's British Railways and the rolling

stock leasing firms built a range of specialised vehicles for transporting new

motor cars going to dealerships, these are described in the section on Air

Braked Rolling Stock.

Up to the 1970's there was a great deal of

inter-factory traffic in components. Some of these components were rather

large, for example it was quite common for one factory to build the chassis and

another to add the body. The chassis or the bodies were often moved by rail. In

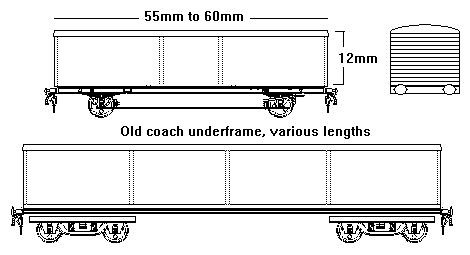

the 1920's the GWR built some special vans with tarpaulin sides for carrying

car bodies from Oxford to Coventry. These were originally built on forty five

foot long 'Macaw' bogie flat wagons with characteristic heavy under trussing

and coded BOCAR but the loads were too light to justify using such heavy

vehicles. In 1934 a number of four wheeled coach underframes with lengths

ranging from about twenty nine foot to thirty two foot were converted for this

work (BOCAR B) and some thirty two foot bogie coaches (BOCAR A) were also

re-bodied for this traffic. More of the bogie A type were built just after the

Second World War and they continued in use into the early British Railways era

carrying car bodies from the Pressed Steel Company works at Swindon. The ends

on all types should be about 12mm high for an N Gauge model.

Fig___

GWR BOCAR

Modelling these vehicles is not too difficult, the chassis

for the four wheeled GWR vans presents the biggest problem but a Peco fifteen

foot brake van chassis with the foot boards removed and extended with a short

length cut from a similar chassis could be used. The Graham Farish fifty seven

foot coach chassis can be used with the battery boxes removed as described

above. The ends can be made from 1mm scribed card and the sides can be made

from paper or plastic card with a covering of crumpled and smoothed out

cigarette paper. The roof represents the biggest problem, you can roll one from

thin metal or for a plastic strip round a tin can using hot water but the easy

option is to beg a second hand Venetian blind and cute strips from that.

The LMS also built a number of Bocars, I believe these were broadly

similar in appearance to the bogie GWR types, but I am unable to confirm the

date of introduction or exact dimensions. Some LMS bocars were open car

transporters as described above, again I cannot confirm their date of

introduction.

There were also a number of air braked vans built for

components traffic, these are discussed in the section on Goods Rolling Stock

Design - Air Braked Stock.

High capacity vehicles

Railway vehicles up to

about thirty foot long could run on a single chassis with four or six wheels,

although the tight curves in some locations meant there were often restrictions

on the longer stock. Where heavier loads were expected or where the vehicle was

longer than this the body was mounted on separate swivelling trucks, called

bogies. Usually these bogies were four wheeled but where exceptionally heavy

loads were anticipated six wheeled bogies were built. One of the early large

dining coaches actually had eight wheels on each bogie.

In the 1880's

there were experiments with larger vehicles, interest having been provoked by

the success of large rolling stock on American railways. Several companies

built large bogie wagons for minerals, mainly for moving locomotive coal. The

GWR and the Great Central for example both used forty ton bogie coal wagons and

the Caledonian Railway built some bogie iron ore wagons with a thirty ton

capacity. The GWR Loco Coal wagon is sketched under Available Models, Graham

Farish, the GC and CR wagons are sketched below.

The large bulk mineral

wagons were relatively successful, but large general goods stock was restricted

to movement between major centres. Prior to the Second World War about ninety

percent of the freight traffic carried by the railways (other than bulk

minerals) involved large numbers of small consignments being shipped to many

different destinations. General goods took too long to load by hand into the

big vans and open wagons and it was impractical to hold a vehicle until it was

full. The four wheelers had reached an average twelve tons capacity a typical

wagon load was only about six tons, for which a fleet of smaller capacity

wagons was more efficient. In America where the bogie wagon had been developed

the pattern of freight movement was different, journeys tended to be longer and

the large capacity wagons were of more use.

Few general merchandise

vehicles were actually put into service at the time (the GWR built a single

bogie open wagon) but the small numbers of large high capacity vehicles were

built at intervals for the following fifty years. The GWR wagon ended its days

carrying paper between Penarth Docks and a paper mill at Ely (near Cardiff).

The the sketch shows its final incarnation as a four plank wagon with two doors

per side, suitable for periods from about 1920 to 1937. The bogies were a plate

frame type similar to the old style coach bogies but with a shorter wheelbase,

these would be difficult to model.

Fig ___ GWR bogie open wagon

Thirty ton bogie open general merchandise wagons were also tried

by the Lancashire and Yorkshire Railway and Great Northern Railway.

Some traffic such as fish was by its nature suited to larger than

average wagons although these had relatively low payloads due to the way the

fish had to be carried to avoid crushing. Both the Great Central and North

Eastern railway built some very large fish vans, including some bogie stock.

The other disadvantages of large bogie stock were that it usually

required a locomotive to move it, the all-up weight was more than a lot of

industrial tracks could carry and clearances on curves in some locations were

too tight for them. Railway locomotives are expensive machines, steam engines

were relatively labour intensive and temperamental, men and horses were

generally readily available and considerably cheaper.

Even the bulk

minerals side had its problems with large wagons as the facilities for wagon

handling had been built with smaller vehicles in mind. A good example is the

coal hoists in the Welsh docks. These lifted wagons up a tower and emptied the

coal by tipping the wagon over a chute. The largest wagons the hoists were

designed to take were the GWR twenty ton four wheeled coal wagons and could

they not handle the much larger bogie wagons. In Britain the high capacity

vehicles remained very much the exception rather than the rule and it was the

1970's before larger vehicles became commonplace. They do however make

attractive models.

Fig ___ Large capacity vehicles

The sketch of the GC bogie open is from an illustration in a

book by O. S. Nock. This was a thirty ton all steel mineral wagon built by the

Great Central Railway around the turn of the century. Note the body overhangs

the sides of the chassis and the T section external straps are continued down

at an angle to the bottom of the solebars.

The iron bodied bogie van is

a Great Western Railway design, the first examples were built in 1904. These

vans were used for high speed goods trains from Bristol and Avonmouth docks to

London and Cardiff.

The Great Northern Railway open wagon was

introduced in 1921 specifically for the carriage of bricks from the brick

fields near Peterborough to the London market.

The Caledonian Railway

30 ton 'ore' wagon was used to supply the iron and steel works around Glasgow.

The North Eastern Railway bogie hopper was used to carry coal from a

colliery to Blyth docks, where it emptied into ships via a raised wooden

'staith'. There were about a hundred of these unfitted NER hopper wagons built

but they were run in short trains to suit the way the colliery worked. It is

worth pointing out that the Gross Loaded Weight of the impressive looking NER

hopper wagon was about fifty six and a half tons but the load carried was

smaller than the modern and much smaller PGA four wheeler 'aggregates' hopper

wagons.

^

Go to top of page

International Good Guys ~ Making the world a

better place since 1971 ~ Site maintained by

All material Copyright © Mike

Smith 2003 unless otherwise credited