Track

Rolling a wheel along a prepared track or 'way' is an old

idea, the Babylonians carved ruts in stone paved roads to guide wagon

wheels along. This technique was also used by the ancient Greeks and

after them the Romans, who built some roads in Britain with ruts at

their standard wagon wheel spacing or 'gauge' of about five foot

(1.5m).

In the early seventeenth

century wooden tracked railways used wooden wheels with

flanges running on rectangular section rails (technically called

'edge rail') appeared at British mines and reached quite high levels of sophistication. In 1992 a

short section of wooden track including a set of wooden points, was

unearthed at the site of an old iron works at Bersham near Wrexham.

The track is believed to date from the early eighteenth century. The

rails were made of elm attached to oak cross-ties or 'sleepers', the

two being held together with wooden pegs, the gauge or distance

between the rails was just over four foot (1.22m). The word 'sleeper'

in this context dates from about 1789 and comes from Newcastle (where

many local terms are based on old Norwegian words), it has the same

root on Old Norse as the word 'slab'. The word 'rail' was

already in use for things made from lengths of wood and this is

probably the origin of the term railway (first recorded use 1681) or

rail-road (first used as a description in 1702).

The term

railway and tramway both mean the same thing, rail comes from the

French 'raille', tram from the Germanic 'traam', both meaning a

length of timber or plank. In Britain the term tramway became

associated with light lines operating on or beside conventional

roads, the tracks being commonly in-set into the normal road surface.

The term 'wagon way' was used to describe some early lines but from

about 1850 the British only used the term wagonway for light lines

using horses or men to move small wagons and settled on railway for

anything bigger.

Generally speaking the wooden track used at

mines in the North East favoured a gauge of around three feet whereas

those further south could have gauges of up to five feet. The

difference is believed to be due to the types of coal mine, the

deeper pits of the North requiring smaller wagons with necessarily

smaller gauge.

In about the 1730's people started adding iron

tyres and even iron spokes to wheels. Casting iron wheels or tyres

with a flange proved difficult at first and an alternative was to use

normal un-flanged wheels (usually fitted with iron tyres) running on

L section iron rails. This kind of track became known as a 'plate

way' and they were favoured by Benjamin Outram, one of the pioneers

of tramways in the late eighteenth and early nineteenth centuries.

Plate ways were initially used to transport goods short distances

from mine or quarry to a nearby canal but some lines were up to

thirty miles long. Outram favoured a gauge of four foot six inches,

which was also the standard distance between cart wheels in his home

area. He believed ordinary road carts could use his tramways but in

practice the reverse happened with his flat wheeled wagons being

dragged off the plateway for road delivery to the customer. L shaped

metal track was common by the 1870's, reaching the Welsh quarries and

mines in the 1890's.

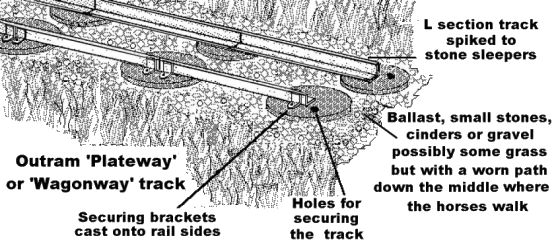

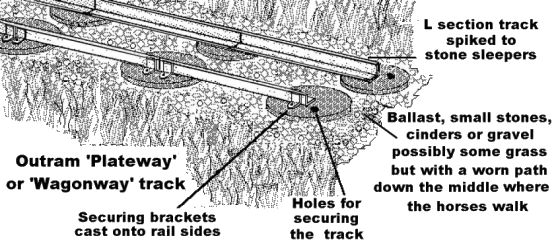

The L section plateway rails were bolted

or spiked down to wooden cross ties (or sleepers) to keep them a

constant distance apart. This was building on existing technology

developed for the wooden railways in mines and quarries.

Unfortunately untreated wood had a tendency to rot and after about

1800 various people began using stone blocks laid in rows under each

rail. There was nothing linking the two rails together but the blocks

were heavy enough to prevent the tracks moving. Generally the L's

faced outwards and the stone blocks were usually either square or

roughly circular with a hole somewhere about the centre. A wooden

plug was driven into the hole and the track was secured to this with

a metal spike.

This L section track is of relevance to the

modeller because it remained in use for 'wagonways' into the 1940's.

These light lines were used for moving stone blocks from a quarry to

a railway loading bank and for small trucks carrying coal or ore from

minor mines to a nearby railway. Some of these lines used steam or

petrol engined locomotives but most used men and horses to move the

wagons. This kind of track can be represented using Plastruct

'fineline' (polystyrene) L section but this is really rather too

heavy and it is better to build up lengths from Slaters 10x20 thou

microstrip glued into an L section. Typically the rails would be

perhaps three foot (1m) long, often with the stone supports only at

their ends. The stone sleepers or setts were usually of fairly

regular shape, typically a foot or so (30 cm) across and one option

is to use a leather punch to obtain small discs from ten thou plastic

card.

Note you cannot use long strips and form them into a

curve, the rails were straight and curves were formed from a series

of 'dog-leg' bends, presumably using rails of slightly different

lengths. If you do make the rails from long lengths bend them at the

'joints' to form the curve. Normally, judging from photographs, on

long straight sections the sleepers seem to have been set in pairs

directly opposite each other.

Fig___ L shaped track on

stone sleepers

In

the early 18th century a firm in Shropshire produced cast iron

flanged wheels for use on wooden rails. In the 1760's an iron

foundry, again in Shropshire, started laying iron bars along the top

of their wooden rails partly to protect the rails and partly to

stockpile the iron plates. The men who did the work were called

'plate layers', a term which remains in use today for staff employed

in laying and maintaining railway track.

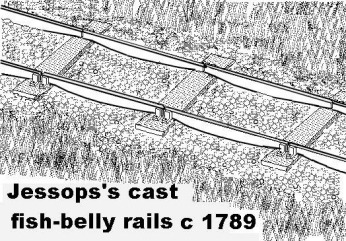

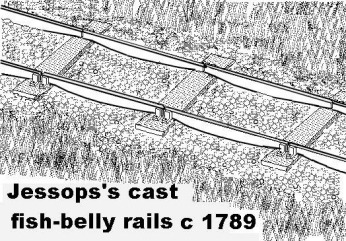

Crude cast iron

rails were first used by Richard Reynolds in 1762 but the ancestor of

the modern rail was devised by William Jessop in 1789 (Mr. Jessop

also introduced the first workable iron points at the same time).

Jessop favoured the flanged wheel with flat topped 'edge' rail over

Outram's L shaped rail and although he was in partnership with

Benjamin Outram the two seemed to have agreed to differ on this point

and their firm produced both types of track depending on who was in

charge of a particular project. Jessop's iron rails were made in

three foot (1m) to six foot (1.8m) lengths, there were side plates

cast onto the rail through which bolts secured the rail to stone

sleepers and the centre of the rail was of deeper section than the

ends. This is called 'fish-belly' rail and it was used for a number

of light wagonways from the 1780's.

Fish bellied rail was not

as common as the L shaped rails on minor tramways and wagonways

feeding full-size railway loading points but it remained in use in

some remote locations up to the 1940's mainly carrying horse drawn or

man-pushed mineral wagons. It is less easy to model than the L

section type and probably not a practical proposition in British N

although you might manage to glue short lengths of 10x10 thou strip

to the bottom edge of 10x20 thou strip. These rails were only made in

straight lengths so again if laying a curve from a single length of

strip remember to put it down in a series of 'dog legs'.

Fig___

Fish-bellied rail laid on wooden sleepers

This sketch taken from a short length of preserved tramway

track, each rail is only about four foot long (1.3m).

In 1797

edge rails were cast with no built-in feet or fixing holes, these

were mounted in cast iron brackets called 'chairs' and the early

examples used wooden sleepers. This system of rails and chairs became

the norm for railways built after the beginning of the nineteenth

century.

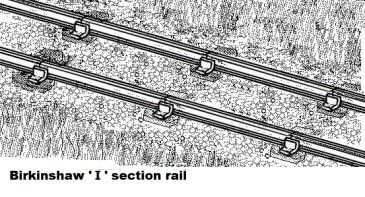

In 1820 an ironmaster called John Birkinshaw

patented an improved rail with a thicker section at the top and

bottom, forming an I shape and this basic design became the norm for

railway track. The rail lengths were laid in the brackets secured to

either stone slabs or wooden sleepers and a wooden wedge was driven

in to hold the rail in place. In early days the wedge was driven in

on the inner face, after about 1900 everyone changed to driving it

into the outer gap. This shape of rail and method of fixing became

the norm on British railways. In the 1970's the wooden chocks were

replaced with spring steel chocks.

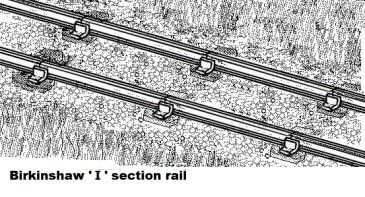

Fig___ Light ' I '

section rail

At the rail ends Birkinshaw added special chairs

to hold the rails together but in the 1840's someone came up with the

'fish plate', these comprise two short lengths of metal bolted across

the join at the end of the rails. The plates are just over a foot

long (30cm) and have four bolts passing through them. Two-bolt fish

plates were tried in the late 1930's so that the sleepers could be

placed closer to the rail ends and provide greater support, this did

not prove to be a success however.

The joints are where the

most problems occur in track and the unsupported 'fishplate'

joint suffered greater wear than Birkinshaw's joining chairs but

fishplates and bolts remained the standard system for joining rails.

Welded rail (discussed later) is now standard for all main line

tracks but fishplates are still used in yards or where points or

other complex track is joined.

Fig___ Photo of

bullhead I section rails joined with fishplates

Most of the wear on a rail happens on the top surface

but experiments with 'reversible' rails that could be turned over

were not a success as the 'chairs' which hold the rail wore on the

underside in use. This lead to the development of 'I' section rails

with a thicker section at the top called 'bullhead rail' which became

the standard in Britain until after the Second World War.

The

design of rails has evolved quite slowly as technology improved. Cast

iron tends to fracture and there was much debate as to the best

cross-sectional shape. One of the pioneering railway engineers, a

chap called Vignoles, designed an I section rail with a flat bottom

and a thickened top edge for the Liverpool & Manchester line in

the 1830's. Vignoles wanted to bolt the flat bottomed rail down onto

to timber strips running along the under-side to support it with

wooden cross sleepers to keep the rails the correct distance apart.

This arrangement for supporting the rail is called 'baulk road' and

in the South West I. K. Brunel used the baulk road idea for the Great

Western Railway. Brunel used an inverted U shaped rail called 'bridge

rail' for his track.

By the 1840's most British companies

were using bullhead rails carried in cast iron 'chairs' but in many

parts of the world the Vignoles flat-bottomed rail was preferred,

held down with spikes hammered into the sleepers.

The

very first steel rails used in the UK were laid at the Midland

Railway's works at Derby in 1857 but they were thrown away after

sixteen years service. There was some initial doubt about using steel

for rails because although it lasted much longer at the time it had

no 'scrap' value. This soon changed however and from the 1870's

rolled rails of 'Bessimer' steel had become the norm for all new

track.

Rail is supplied to the railway company in straight

lengths and is transported in this form through the system. The

standard rail length stabilised at about thirty foot (9.1m) until

after the First World War when forty foot (12.2m) and forty-five foot

(13.7m) rails appeared as steel rolling technology improved. By the

1930's sixty foot (18.3m) rail lengths were standard on main lines

and rails of up to a hundred and fifty or so feet were supplied to

the LNER and LMS companies. With Nationalisation the sixty foot rail

was adopted as the standard. Longer rails required longer wagons to

transport them and bogie designs were introduced by several companies

as rail lengths increased.

Rail taken from Peco or other

track is not suitable for representing rail loads on wagons as it is

way over scale. The best option is to use the finest 'I' section from

the Plastruct range (reference BFS-2), do remember that all the rails

would be of the same standard length and take care when cutting.

Where curves and complex track such as points and crossings

were needed they were made on the spot from standard rail lengths.

Teams of men cut the rail with hacksaws and bent the rail with

levers, chocks and pulleys, power tools did not exist so every hole

had to be drilled in the metal using hand drills.

As the

train passes through the curve the most wear occurs on the inside

face of the outer rail. To help reduce the wear on very tight curves

some companies added a felt pad, laid against the rail and with its

bottom edge sitting in a trough of oil. As the wagons passed they

pressed the felt, picking up some oil on their flanges as they did

so. An alternative system employed small plungers, operated by the

wheel flanges, which squirted grease onto the rail side. Even with

the lubrication the rails tended to wear and standard practice was to

exchange the inner and outer rails every few years to even the wear.

Rails are defined by their weight per foot or per yard and

the weight of rails has risen steadily over the years. Early lines

used iron rails of as little as forty pounds per yard, quite soon

steel rails of eighty pounds per yard appeared and by the turn of the

century everyone was using ninety odd pounds per yard for new rail.

In the early twentieth century, following an accident at a major main

line junction, it was found that rails ranging down to forty pounds

per yard were still in use, prompting the companies to check and

replace the older track. In 1921 the Government laid down a national

standard of ninety four and a half pounds per yard plus or minus half

a percent (this was in fact slightly lighter than the GWR's standard

rail at the time). These days the rail weight is not nearly so

standardised I contacted Railtrack on this in 1999 and they advised

me that although they could quote for specific sections the data for

the heaviest and lightest on the network was not directly

available.

I enquired on the newsgroup uk.railway regarding

the actual weight of rail and received the following replies:

I

thought Railtrack standardised on UIC60 rail (60 kg/m) some years

ago, at least for new main-line schemes. However, I don't know

whether they continued to buy earlier specs for replacements on other

lines.

Roger

UIC 60 (60kg/m) only seems to be used

on the higher speed main line routes, the only places I've noticed it

is on WCML renewals, although it may be used elsewhere. Otherwise

most renewals I've seen still seems to be using Flat Bottom 113A (113

lb / yd) on F 40 sleepers or EF 28 sleepers on Southern Region. (It

seems the use of "zone" has been discontinued)

All the

UIC 60 I've seen has been laid on G 44 sleepers with pandrol fastclip

fixings, but as I've never actually re layed any I couldn't say if it

can be laid on F 40 type sleepers for standard re railing or whether

its use requires G44 sleepers and therefore is only practical for use

on renewal projects. (There may also be load gauge issues associated

with its use for re railing as it is a deeper profile.)

HTH,

Kevin

To put these comments in context with

the earlier figures 60kg is 132 lbs and 1m is 1.09 yds so UIC60 track

weighs in at 121 lbs per yard. UIC60 rail is a heavy duty rail and

has been approved by the International Union of Railways (UIC) for

use on high-speed lines throughout Europe.

The payload of

goods vehicles has increased steadily since the Second World War, in

1948 the maximum weight per axle was seventeen and a half tons. This

was increased in 1962 to twenty two and a half tons giving rise to

the 'big' forty five ton wagons such as the Peco long wheelbase tank

wagon. In 1966 the axle weight was again increased, to twenty five

tons, but initially this was only on specific routes. By the 1990's

most of the network was allowed to carry twenty five tons per axle

and on some routes greater loads are permitted, allowing the very

large one hundred and two ton bogie tank wagons to operate.

In

the days of steam hauled trains the heaviest element in the train was

normally the locomotive, differing weights of rail and the strength

of viaducts and bridges under the track all contributed to

restrictions on the use of the heavier locomotives. Each line was

classed in a table of 'route availability' (usually abbreviated to

RA) on a scale of one to ten. The locomotives were similarly

classified and were allowed to operate only on lines which were able

to bear their weight. Typically the locomotive would have a coloured

disk painted on it to indicate the minimum RA class on which it could

safely operate.

Post privatisation Railtrack retained the RA

classification system, although it is normally the freight vehicles

these days which push the limits of the per-axle weight.

Track

rated at RA1-6 is the most common and can carry up to 20.3 tonnes per

axle, RA7-9 allows axle weights of up to 24.1 tonnes and RA10 can

carry up to 25.4 tonnes per axle. in the 1990's RA7-9 was used

for a network of freight lines around London, for the West Coast Main

Line up to Carslile and in areas where there are industries which

generate heavy freight flows. RA10 was confined to a couple of lines

in Scotland, a similar number in Wales and a number of short sections

which regularly handled very heavy freight.

As noted above

the joints in a track are where most of the wear occurs to both rails

and wheels, nearly half the work done on conventional track is in

maintaining the joints. Modern practice favours the use of long

lengths of welded rail, made up of standard sixty foot (18m) lengths

with their ends welded together to create continuous rails of up to a

mile or so (1.6 km) in length. Welded track offers not only a

smoother ride but also, thanks to the reduced number of joints,

requires much less maintenance.

Welded track was originally

developed in America in the late 1930's, notably on the Delaware &

Hudson Railway in 1937 where it was known as the 'Velvet Track'. In

America they tried welding lengths of line up to half a mile long

then transporting this on a fleet of wagons to the site, they found

the long rails curved easily to follow even quite severe reverse (S

shaped) curves. In Britain some long rail sections were moved on long

rakes of redundant long wheelbase twin bolster wagons (similar to

those offered by Peco), purpose built rail carrying wagons have always been used by the railways, where long lengths of welded track are used these are carried on specially designed bogie wagons. The photos below show such a train comprised of JZA wagons passing through Manchester on a rather dull winters day in 2005.

Fig___ Photograph of a welded rail train

I understand that lengths of up to 230 yards

can be supplied from the steelworks these days (thanks to continuous

casting methods) but in N the rails would not bend so this is not

really an option.

Most welded rail in Britain has been welded

on-site using a special train which lifts the track, runs it over a

series of wagons where it is welded and ground smooth, then re-lays

it behind. Once welded and laid on the sleepers the rail is heated

and the securing clips banged into place, as the rail cools it tries

to shrink but it is held by the clips to the heavy sleepers. This

pre-tensioning of the track eliminates, or at least greatly reduces,

the danger of the rails expanding too much in hot weather and

buckling. In the mid to late 1990's a new technology called 'flash

butt welding' was introduced, this employs a machine able to run on

road or rail which can rapidly weld plain rail ends together very

quickly. This technology allows shorter rail lengths to be welded and

hence allows for track with fewer joints even close to points and

crossings.

Fig___ Photograph of a joint used with

welded rail

Even with the pre-tensioning allowance has to be made for

expansion in hot weather and contraction in the cold. Welded rails

therefore have special 'expansion joints'. As the lengths

of rail involved are long the cumulative expansion is large so at the

joint the ends of welded rail are cut to wedge shape and a special

chair is fitted to hold the ends together.

The joints are

only about eighteen inches long and quite difficult to spot, the

give-away is that two lengths of old bullhead steel rail are bolted

across the four sleepers bridging the joint, note these sleepers are

wooden even if the remainder of the track uses concrete sleepers. The

old rail is only about two-thirds the size of the running rail, but

even so it might foul the coupling pin on an N Gauge model. The best

option would be the finest rectangular I section Plastruct Fineline

(reference BFS-2) and sand the bottom sides almost flat before gluing

the two lengths in place. Welded rail has no joints in the old sense

of the term and hence eliminates the clickety-clack noises of the

older tracks.

The Liverpool & Manchester Railway of

1830 settled on fish-bellied rails some fifteen foot (4.5m) long and

each supported in seven cast iron chairs. They experimented with both

wooden sleepers and stone blocks but with the development of

effective wood preservatives they found the wooden type preferable

and this became the norm. Porous wood is used as this absorbs more

preservative (the average sleeper soaked up about three gallons of

creosote) and wooden sleepers can last up to twenty-five years in

service. Where there was a danger of fire, such as on the great

timber 'fan' viaducts built by Brunel, the wood was not soaked in

creosote but instead treated with a more expensive mercury based

liquid.

The LNWR tried iron sleepers but this was not a

success and various companies including the LNWR and GWR tried steel

sleepers, but again these did not catch on in the UK. Everyone

settled on Baltic Redwood timber sleepers, originally nine feet

(2.7m) long, reduced to about eight foot six (2.59m) with the

shortages caused by World War One. With the advent of the Second

World War, and after that the Iron Curtain, Baltic timber became

unobtainable, Canadian Douglas Fir was tried but this proved less

than ideal and interest focused on concrete sleepers.

The

earliest reference to concrete sleepers I have found was on the

distinctly different Weston, Clevedon & Portishead Light Railway

who used them from about 1909. The sleepers were unconventional in

design, rectangular concrete blocks linked by transverse iron rods

similar in appearance to the old stone block sleepers. These proved

something of a success on the WC&PLR but other companies had

little success with concrete sleepers of more conventional design as

they tended to crack in service.

The first general

introduction of concrete sleepers on main lines took place in the

late 1930's. These were of conventional design, direct replacements

for the timber type, and were fitted to carry chairs and bull-head

rail. Concrete sleepers weigh more than wooden types but last fifty

years instead of the average twenty-five for the wooden type, and

with mechanical handling (introduced due to wartime manpower

shortages) the weight was less of a problem. The problems of the

concrete cracking in use have been resolved and concrete sleepers are

now standard for plain track but to date wooden sleepers are still

used for point work. Modern practice favours the use of hardwood

sleepers as these last much longer than the soft wood types. Steel

sleepers, imported from the USA, are in place on some limited

sections of track in Britain but they are extensively used in Europe,

mainly in Switzerland. Steel sleepers are not solid blocks, they are

formed rather like an inverted pie plate with a dished under side,

this saves weight and cost and helps the sleeper bite into the

ballast. They are not ideal however as they lack weight, which is an issue when using pre-tensioned welded rail (discussed below), so they are not suitable for main lines. I have only seen steel sleepers once, stacked by the track side awaiting use. These were 'rust' coloured and had the track fixing clips built-in.

Currently (later 1980s) the railways are replacing about a million

sleepers every year, over half of which are concrete. Old wooden

railway sleepers had a ready market, used for everything from

building heavy fencing to building up flower beds in peoples gardens.

Creosote is distilled from coal tar and contains something called

benzopyrene, in 2003 new research suggested that even the trace

amounts of this material remaining in old sleepers represented a

health hazard. In 2003 the European Union sponsored legislation

banning the sale of old wooden sleepers. Network Rail is therefore

faced with a problem of what to do with them, one option being

considered being to build a special furnace that can use chipped

sleepers as fuel (examples of which are already operating on the

continent).

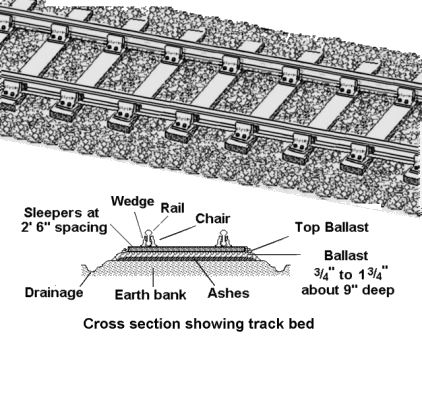

Railways require a stable base or track bed,

after rain the earth softens and the track becomes uneven. The

wagonways of the North East were mainly built to carry coal and ore

to the ports, the ships arrived filled with a 'ballast' of broken

stone and gravel and this was taken and used by the railways to form

a path on which the track was laid. This allows rainwater to drain

away giving a more stable surface and the term 'ballast' has remained

in use ever since to describe the broken stone path along which the

railway runs.

In the 1870's there were several derailments

caused by rails breaking, the railway companies blamed the quality of

the steel used for the rails and suggested it had been weakened by

exceptionally cold weather. The British scientist Joule decided to

experiment to test this idea. He used nails and needles for the

experiments, this was the first time someone conducted such an experiment where the materials used were scaled down and there was much debate about the validity of scaling

things down in this way. He found that the steel was actually

strengthened by cold weather, when most of the accidents had

occurred, and that the problem lay in the design of the track bed.

This lead to further experimentation by the railway companies and the

development of a standard method for ballasting track.

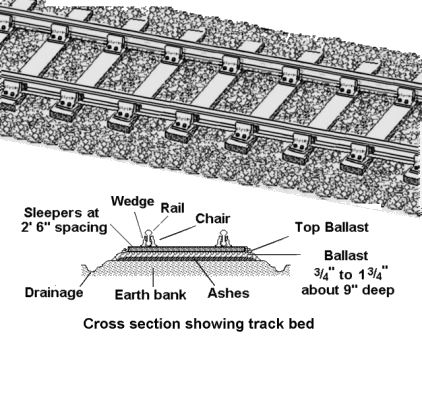

Fig___

Bullhead track and cross section of track bed

Most lines used crushed stone ballast, limestone and granite

were both common. These materials start off white but soon develop a

coating of brown or rust coloured brake dust and black sooty deposits

from the steam locomotives. Since the introduction of diesel power there has been a steady

deposit of oil along the track between the rails darkening the

ballast to almost black in stations where trains tend to loiter. From observations on my local line it has

taken three years to turn the fresh laid white ballast to a patchy

brown.

Other ballast materials were also

used, depending upon what was available locally, in Wales broken

slate was common in the North and the dark waste from lead mining was

common in the South.

Some ballast had high levels of toxic impurities

(such as the lead mine waste) which inhibited weed growth, where this

was not the case it was (and remains) necessary to treat the track

with weed-killer to prevent the plants clogging up the ballast and

reducing the drainage. Where track was laid in goods yards,

marshalling yards and industrial premises where speeds were slow and

uneven track was not such a threat a simple bed of ashes and cinders

was laid. The track in these areas was not on a raised earth bank and

this is clearly visible when you look at a yard area beside a main

line. If you are using cork strip under your track do not use this in

yard areas and paint the ballast and surrounding ground black.

On

quiet branch lines ash ballast was also sometimes used for the

running lines, although this would be laid on a conventional earth

bank to assist drainage. Ash ballast tends to allow the track to sink

deeper in than broken stone, often it crept up to the sides of the

rail and its finer appearance is relevant to the modeller. Fine sand

serves for conventional ballast, for ash something rather finer is required, I have had success with Chinchilla sand (from the pet shop). I use this for conventional broken stone ballast as well but it can be smoothed down with a wet finger after the glue has been added, producing a much flatter surface resembling ash and cinders. Ash and cinder ballast was (certainly in sidings remembered from my youth) almost black, presumably when freshly laid the ash would have added shades of lighter greys. When gluing the

finer material down using the usual syringe of diluted PVA glue I

have found it tends to contract and crack when drying so I add a thin

coating of undiluted glue over the top and sprinkle on additional

material in the affected areas.

One variation on standard

track is 'inset track', where the track is set into the surface of

road or yard area. The first use of this kind of track was in 1852

when Frenchman Emile Loubert used it for tram rails in the street.

Inset track became the norm for trams running in city streets

but it was not common on railways. A few areas in goods yards might

have inset track, and where light railway or industrial siding lines passed along public roads the track

was set into the road surface, but their main use was in industrial

locations and docks. In dock areas inset track was common but it costs more to lay and is more difficult to maintain so it was avoided where possible. As an example in the Trafford Park industrial estate in South Manchester the rail lines were all conventionally ballasted track beside the roadways, only being inset where they crossed roads.

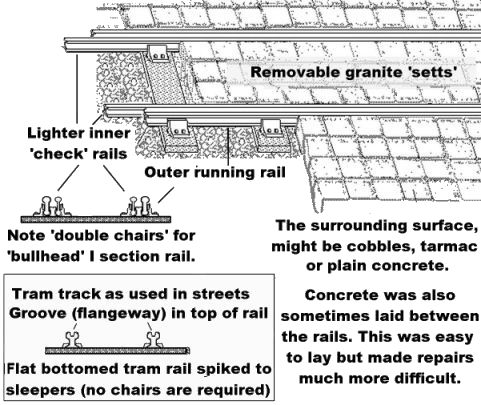

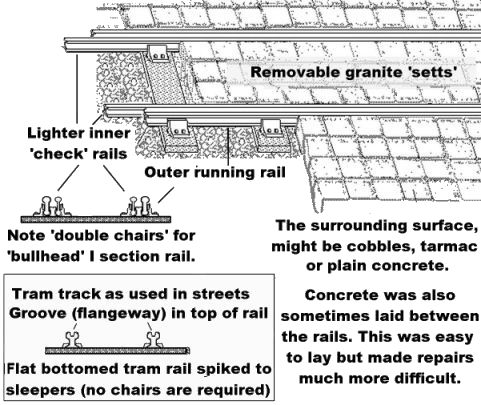

Inset track could be laid using either

pairs of standard rails (with one laid as an inner 'check rail') or

specially rolled 'tramway' rail as shown in the drawing below. Note

the 'tram' rail is actually a single rail with a groove in the top

for the flange of the wheel. This flat bottomed rail is secured

directly to the sleepers with steel spikes. Tram rails were not

suitable for railway rolling stock as the groove was too shallow (the

flange on tram wheels is much smaller than on a railway wheel).

Specially produced inset rail suitable for railway wagons was used in

some locations but as the railways had a plentiful supply of standard

bull-head rail requiring only double versions of standard chairs the

twin rail arrangement was common.

Fig___ Inset track

Where the lines handled normal railway traffic the surrounding

road or yard surface was built-up to the height of the rails and the

gap between the inner rails would then be filled using stone setts

which could be removed for track maintenance as required. The

surrounding area was generally concreted after about 1920, and after

about 1930 a top coating of tarmac was often added. From the later

1930's, particularly on dockside lines, the ground was excavated, the

track was laid, then concrete was put down to build up the level. The

disadvantage of concreting in the track in this way was that

maintenance became a lot more difficult and in goods yards it was not

uncommon to have the road surfacing built up to either side of the

track but with the sleepers exposed between the rails. This open kind

of track is much easier to model in N, especially where the lines are

curved, and short inserts can be provided where road traffic might be

expected to cross the line. The illustration below, based on a photo taken in the 1930s, shows some inset track in a goods yard, note that the point switch rails are cut and hinged, the excavated area shows how long the hinged sections were. The point lever sits in a stone block, so it will not be damaged by passing road vehicles or trip up horses, in use the lever is lifted slightly, dragged round through 180 degrees, then folded back over and into the slot. The metal drum in the rear left is a 'capstan', discussed further in the section on turntables points and slips. By the 1970s the in-fill between the rails was no longer there (the stone road surface outside the rails was still in place) and more conventional points were in use in this yard although the capstans remained in place until closure in 1975.

Fig___ Inset track in a goods yard, note the design of the point blades

Inner 'check rails' were also

fitted to normal track where curves were tight as they helped prevent

derailments. They were first used as far back as 1729 on a horse

operated wagonway in County Durham and they were used on the steam

hauled railways wherever the curves were less than about six hundred

foot (183m) radius. That is equivalent to over four foot radius in N,

or 1.2m, which gives some idea of how tight model railway curves tend

to be. Check rails are still seen today on tight curves, note that

the check rails are only laid with the inner rail on the curve.

Abroad many railways settled on flat bottomed rails (Vignoles

section rail) spiked directly to wooden sleepers, this meant that the

heavy cast iron chairs were not required which saved on transport

costs. In the event however it was found that it was necessary to add

a steel base plate to the wooden sleepers to carry the rail.

In 1949 British Railways changed to using flat-bottomed

Vignoles section rails. The rails were spiked to wooden sleepers or

bolted down to concrete sleepers with special clamps but in 1957 a

Norwegian engineer invented the Pandrol clip. This uses a simple flat

plate with cast-in loops, the Vignoles section (flat bottomed) rail

is laid in the chair and a twist of metal, the clip itself, is

hammered into the loops to hold the rail in place.

Fig___

Flat bottomed rail and Pandrol Clips

The Pandrol clip

tightens under vibration, which prevents the problem of trains

dragging the track along when the brakes are applied. Pandrol clips

save a lot of time and effort, the clips can be hammered in by a man

with a big hammer or by a rail-mounted machine, they are now in use

in over sixty countries. Pandrol clips appeared in the UK in 1959 and

they are now the standard rail fixing throughout Europe and in many

other parts of the world. The latest (late 1990's) designs of Pandrol clip use a

flatter profile.

In the 1980's a new system called paved

concrete track (commonly abbreviated to PACT) came into play. This

uses a continuous ribbon of concrete onto which the rails are usually

secured using Pandrol type clips. PACT track is widely used in

railway tunnels and for 'rapid transit' passenger rail systems and

the Japanese have used it for their new high speed lines.

In

1998 the European Union arrived at a basic understanding on a set of

international standards for track. This agreement covers the rails,

sleepers, design of points or turnouts and crossings and the method

of securing the rail to the sleepers. The Pandrol clip is the

standard fixing, Pandrol are now a British based company but supply

most of the European railways.

Noise pollution is nowadays an issue and there is a Europe wide initiative to

reduce the noise and vibration cause by passing trains. There were

three separate lines of enquiry; Silent Freight (looking at ways to

make freight vehicles quieter), Silent Track (looking at ways to make

the track quieter) and Eurosabot (developing reliable methodology for

designing tread brake blocks that would result in smoother wheel

rolling surfaces). The European Rail Research Institute (ERRI) in the

Netherlands is the co-ordinating body and the research has covered

the shape of the rail, the use of rubber pads between the rail and

sleeper, the wheel profile, modified bogies fitted with 'noise

guards' and the materials used to make the brake shoes used with

'clasp brakes' still fitted to much of the goods stock. Of these

modifications to the wheels, track and brake blocks produced the

least improvement and interest has focused on damping the wheel

vibration and developing the bogie shrouds. It is believed that a

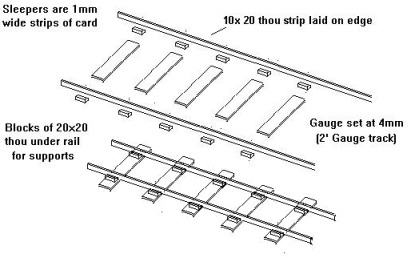

noise reduction of up to 50 percent is possible.

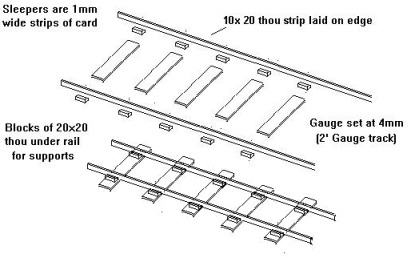

Prefabricated

(portable) Track

In the late nineteenth century an

all-metal prefabricated track was developed for light lines in

quarries and the like. Called Jubilee track it was supplied in

straights and curves with pre-fabricated point units and lasted in

use into the 1940's. The rails were held quite high on Jubilee track,

with daylight often visible beneath them when in use. Jubilee track

can be modelled as shown in Fig___ above using strips of 10x20 thou

strip (laid on edge) with sleepers of 10 or 20 thou 1mm (40 thou)

wide. I would suggest using a simple jig to get the sleeper spacing

constant as this is very noticeable when the track is stacked in the

wagon. Ideally you should add 'feet' under the track to raise it

clear of the sleepers. 1mm lengths of 20x20 thou strip would serve

well, but this would be fiddly and may stretch your patience.

Fig___ Modelling Jubilee Track

On

the horse operated tramways a smaller version of Birkinshaw's rail

was sometimes used in the form of short lengths bolted down to stone

or wooden sleepers. This type of rail was not as common as the L

shaped or fish belly type on these wagonways but it has the

advantage of being much easier to model. Having made two lengths of

track as shown in Fig___ above you then need to draw the line of the

rails onto the baseboard, light railways using this kind of track

ranged from two foot to four foot gauge. Next glue the lines of rail

in place over your drawn lines, making the necessary 'dog-legs' at

the 'joints' and when these have set add a thin coating of fine sand

to represent the ballast. The ballast could be white (limestone or

granite), black (cinders or lead ore), or grey (slate) depending on

what was available cheaply in the area. Add some weeds from teased

out (used) pan scourer between and to either side of the rails and

build up the ground cover along the line.

^

Go to top of page

International Good Guys ~Queuing, patiently, since 1971 ~ Site maintained by

All material Copyright © Mike Smith 2003 unless otherwise credited